Surprise! Crises and disruptive incidents often strike suddenly and unexpectedly. However, with well-thought-out strategies, companies can prepare themselves: good preparation creates room to maneuver in emergencies and helps maintain the ability to act during a crisis. This not only provides security and stability in challenging situations but can even offer opportunities in the form of disruptive innovations.

With strong and robust processes, you can approach important and sustainable decisions more calmly and confidently than many competitors even in times of crisis. This keeps your eyes open for new opportunities, even when turbulence hits.

Not all crises are unforeseeable, but their consequences often are. Recognizing what is happening early and responding quickly must therefore become part of day-to-day operations. Adaptive and dynamic processes that are regularly reviewed and adjusted can provide critical support here.

Together with our industrial partners, we develop customized approaches that cover all areas of the business. With the right strategies and processes, you can improve your ability to continuously adapt production and build a resilient company well prepared for disruption.

For example, we work with manufacturing companies to develop strategies that reduce supply chain dependencies and enable early detection of technologically relevant developments.

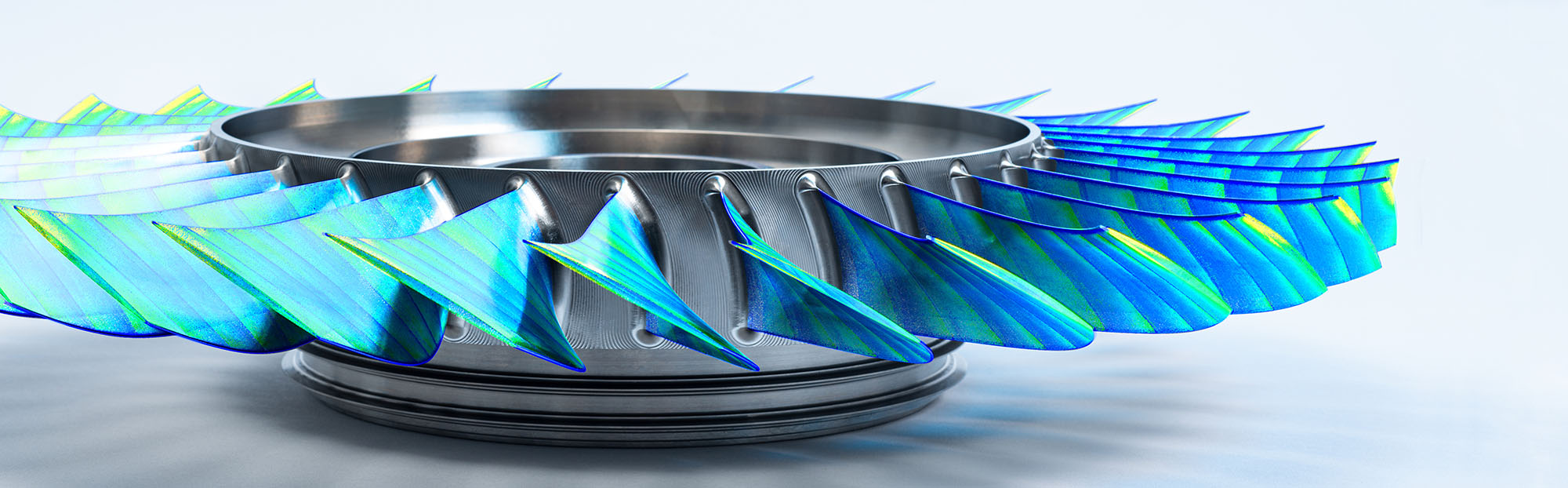

For the evolution of your production systems, we develop modular platforms that allow you to respond to changes, new conditions, and customer needs with agility and cost efficiency. By digitalizing and networking your systems and equipment, we help you enable self-regulation and self-correction key elements of a truly resilient operation.