CO₂ fleet targets, global competitive dynamics, and declining demand in Europe are changing the rules of the game in the automotive industry. For OEMs, suppliers, and the machine building industry, this means that strategies, structures, and technologies must be rethought.

We propose to spit in our hands and start change together. We are convinced that smart minds and the right methods will give the European market a new boost. Industry and research working together provide the key to this.

Beyond the production line: How OEMs become pacesetters again

OEMs face the challenge of maintaining their technological leadership and setting the pace of development despite the currently challenging framework conditions.

Our technology managers and production experts are targeting innovation fields such as driver assistance systems and vehicle digitalization and identifying technologies that will give you a competitive edge: We are focusing on modular, digital production that enables automotive manufacturers to act flexibly even in dynamic times. And even though public funding is currently decreasing, we are developing strategies and production techniques for the expansion of battery and hydrogen technologies in direct cooperation with our partners in the industry.

Suppliers in structural change: Time to change the playing field

The transformation of the automotive industry is forcing suppliers to reinvent their business model. We support you in opening up new markets through targeted diversification and identifying promising applications for your products and production facilities – both in adjacent industries and in upstream or downstream stages of the value chains.

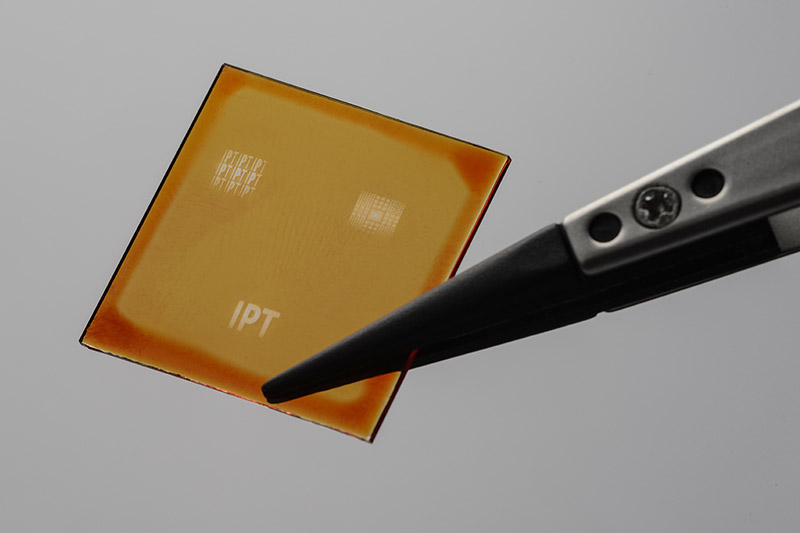

We use technology due diligence procedures to factually and independently evaluate new technologies and start-ups in terms of relevance and investment potential. We also identify untapped markets, such as those emerging in battery and storage technologies related to recycling and circular economy.

Our goal is to work with you to find the right markets, choose the right technologies, and develop sustainable business models – for a stable future beyond traditional supplier business.

Decoupling mechanical engineering: How to break away from the old automotive world

The decreasing demand in the vehicle market is also affecting the order books of the mechanical and plant engineering industry. We help mechanical engineering companies break free from their reliance on traditional drivetrains.

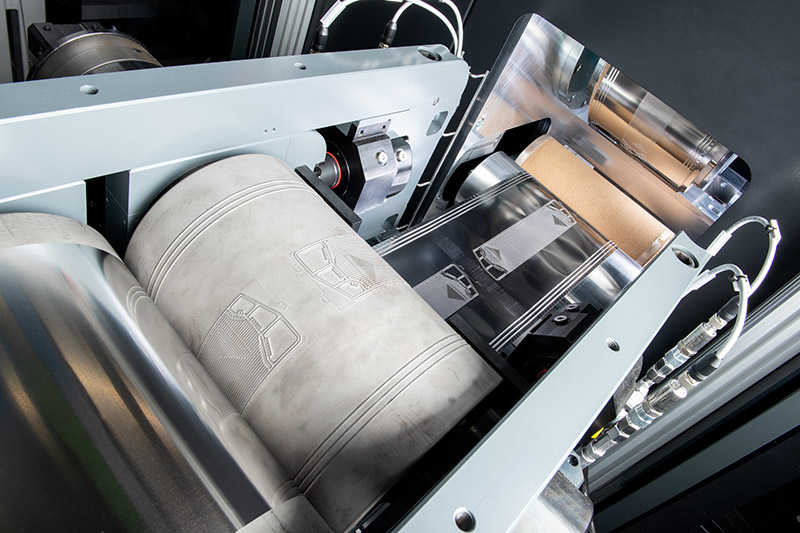

A promising approach is the development of modular and platform-based machine and plant technologies, which allow you to respond more flexibly to different customer needs.

We also promote the targeted development of technological expertise within the company. For understanding and knowledge about central topics such as automation, sensor technology, and software integration are the first steps on the way to new solutions. We work closely with your teams to design training programs that impart technical knowledge and strengthen the internal innovation culture.