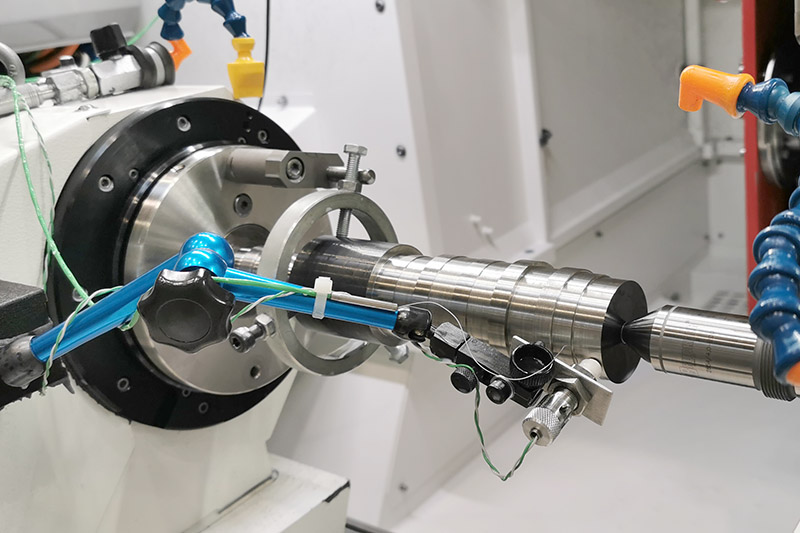

In order to increase productivity, efficiency and product quality, today's manufacturing processes and plants must be designed flexibly and adaptively. This requires the development of increasingly powerful sensor and control technology. At the same time, the manufacturing processes used are becoming more and more complex. Especially in machining, but also in robotics and distributed systems, this means even more complex motion sequences for workpieces and system components. As a direct result, highly reliable and wireless data transmission techniques are required to transfer the data of in-process sensors and control devices and meet the constantly growing requirements for transmission speed and latency.

With low latencies and high data rates, the new 5G mobile technology offers enormous potential for production: Processes can be continuously monitored and documented, and process flows can be configured adaptively in real time. Through the intelligent interaction of the 5G network with local edge cloud systems, continuous real-time applications can be implemented in a scalable manner - from the sensor to the cloud.

The Fraunhofer IPT operates a unique test environment for the future mobile radio standard 5G in cooperation with Ericsson, the Swedish provider of mobile radio and telecommunications technology. In this environment, industrial application scenarios based on the wireless transmission standard can be tested and further developed. With its short latency times of less than one millisecond, high data rates of up to 10 Gbit/s and the ability to operate numerous devices simultaneously in tightly defined radio cells, 5G technology is particularly well suited for use in networked, adaptive production systems with extensive measurement and control technology. The large variety of machines and applications at the Fraunhofer IPT offers the opportunity to use and test the technology in a wide variety of applications.