Regardless of whether special reflection properties of a replicated optic are desired, lower adhesion of injection-molded plastics to the wear-resistant metallic tool, or minimized friction through better distribution of lubricant in the gearbox: Fraunhofer IPT offers the appropriate manufacturing process for very different areas of application and implements it in your production.

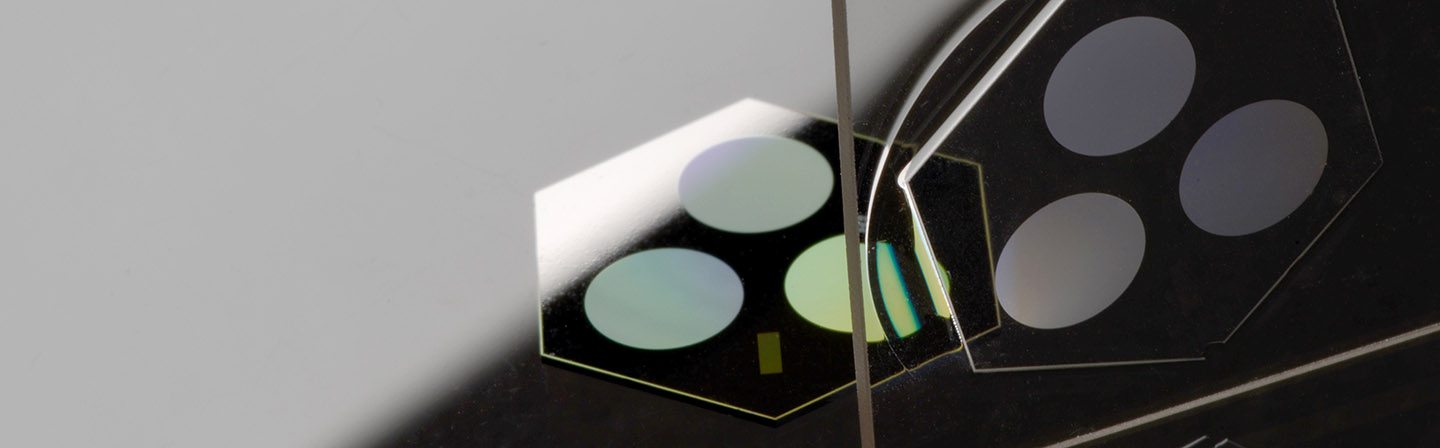

Our technology portfolio includes automated fine machining, diamond cutting, ultra-precise grinding and polishing, micro- and nanostructuring, and pressing of high-precision glass optics. We combine individual processes of generative and replicative manufacturing methods into high-performance process combinations and chains, depending on the desired end product.