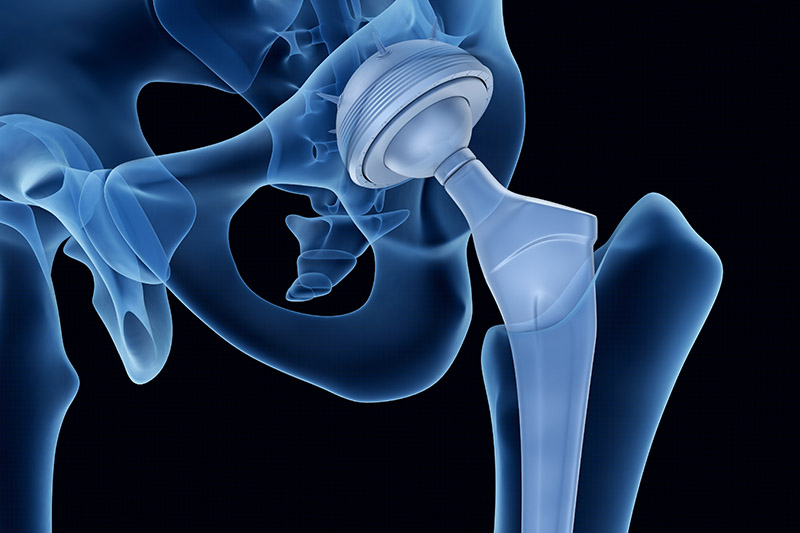

Medical progress requires not only innovative ideas, but also the right production processes, technologies and software to turn them into reality efficiently and cost-effectively. As soon as the “Proof of Concept” has been achieved and prototypes and small series have successfully passed the initial research studies, cost-effective and scalable production processes must be available for the market launch at the latest. Our aim is to accelerate the market launch of your products by integrating them into your development processes at an early stage. In doing so, we always keep an eye on regulations and safety criteria.

The trend in medical technology towards smaller, lighter, intelligent and personalized medical devices is benefiting from software developments, the use of artificial intelligence, device communication and automated production technologies.