From traditional mechanical engineering to the digital, networked world

Process and product understanding are the two cornerstones of modern mechanical and plant engineering. While traditional mechanical engineering still worked strictly with a view to firmly defined, rigid requirements, flexibility in production is now moving forward as the predominant development principle.

Products and services are subject to ever shorter development cycles and the diversity of the product spectrum is constantly expanding. Mechanical and plant engineering can respond to these requirements by linking product and process knowledge more closely and using digital concepts to further increase efficiency.

The use of self-learning algorithms to monitor process and plant states and the networking of all production data within a digital infrastructure pave the way for making production predictable and transparent. High product quality, low scrap and maximum machine utilization remain the goal in mechanical and plant engineering. New technologies and materials as well as the demand for climate-conscious and sustainable production require new recycling and material cycles. Last but not least, politically and socially motivated goals such as the energy turnaround are also shaping the development of new production technologies.

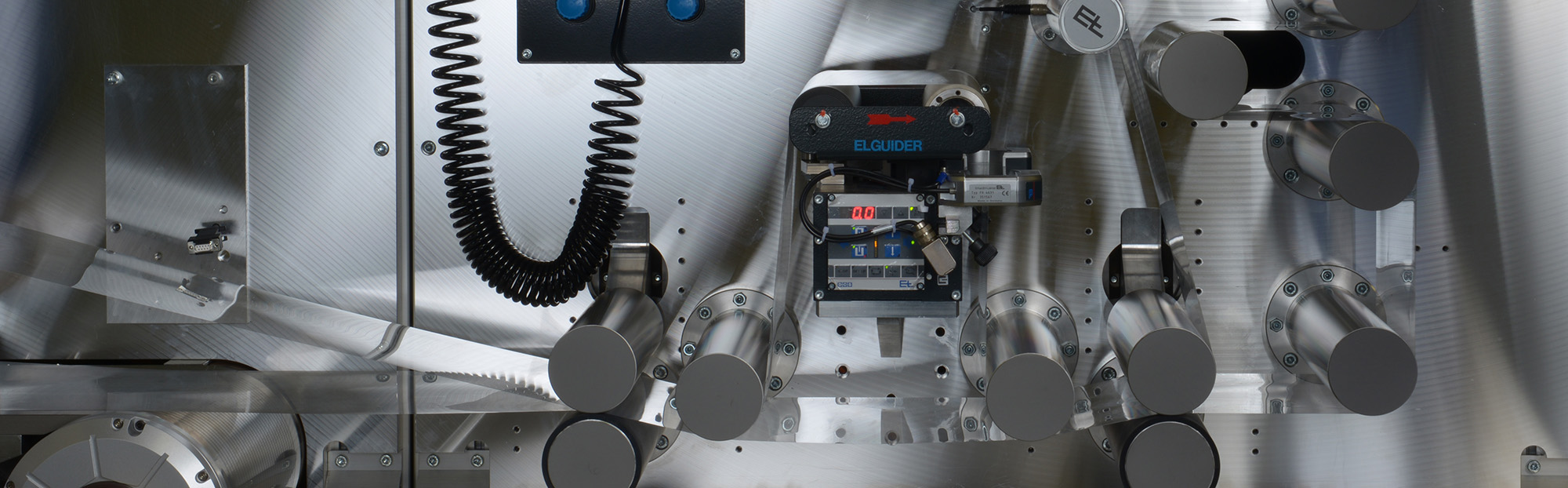

Always at the cutting edge: modules and systems for the digital process chain

Fraunhofer IPT has more than 40 years of research and development experience – both in classic mechanical and plant engineering and in the development of individual and high-performance special machines and system components. We develop and accompany our plants and systems throughout their entire service life. For the complete process chain, we develop individual modules and components in overall responsibility or in cooperation with industrial system integrators. This applies not only to technical development, but also to communication between the parties involved, risk management, and also contractual arrangements, for example in the form of licenses or contracts for work and services.