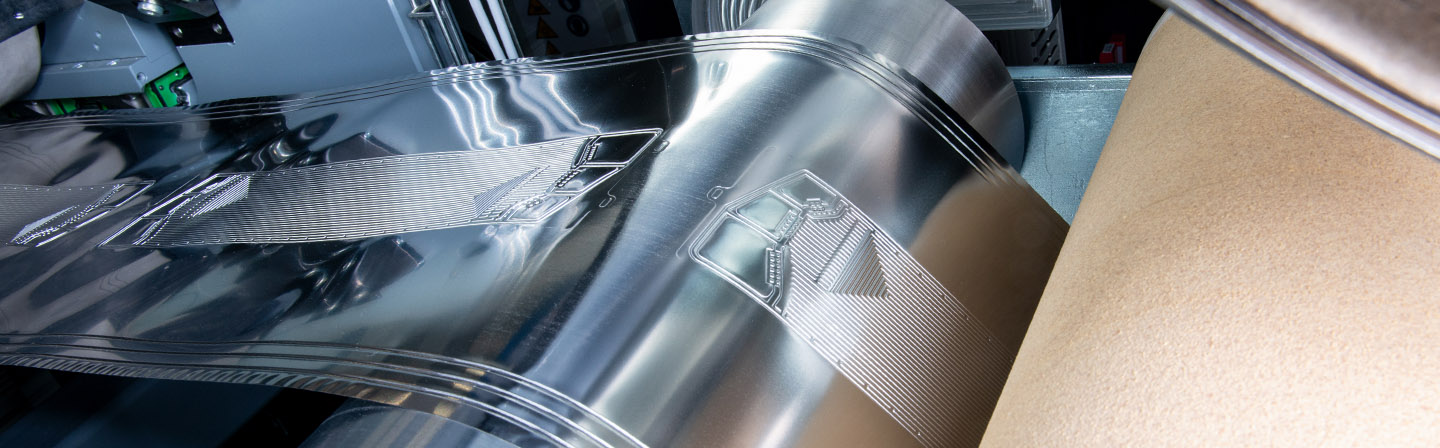

Fast and efficient: functionalizing plastic and metal foils in a continuous process

Applying electrodes to metal films or structuring of plastic films. These two processes have one thing in common: They run continuously via rollers. The so-called roll-to-roll technologies (R2R) are a particularly cost-effective way of producing film materials at high process speeds. In various process areas, the film substrates can be functionalized using structuring processes. In order to test new technologies or manufacturing approaches in continuous production, Fraunhofer IPT is developing modular R2R small- to midscale production lines for plastic and metal films. This enables companies to react quickly and adequately to changes in production, as the modules can be flexibly designed and the system concept can be adapted to different conditions – even after commissioning.

Metal films are used in the production of components for energy storage systems, for example in the manufacture of electrodes for lithium-ion or solid-state batteries or in hydrogen technology as the base material for bipolar plates in fuel cells or electrolyzers. Plastic films are often used for optical, microfluidic or electrochemical applications, for example for the membrane electrode assembly (MEA).

The production of these components offers great potential for applied research into continuous processes. Innovations in R2R technology, therefore, establish important foundations for marketable products.