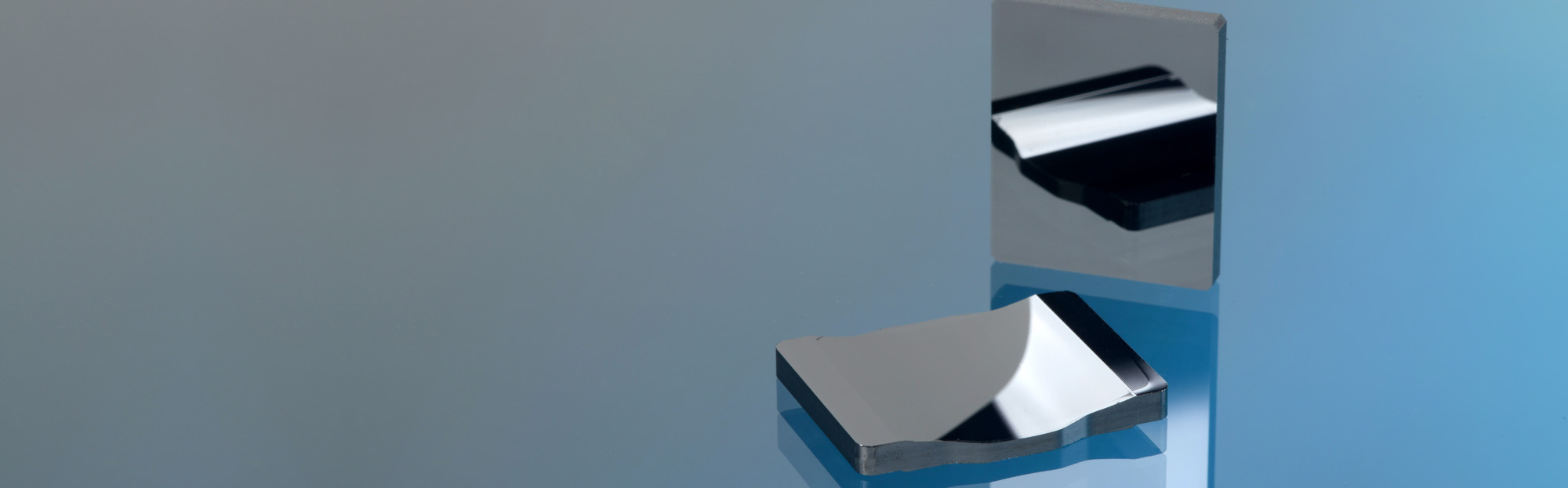

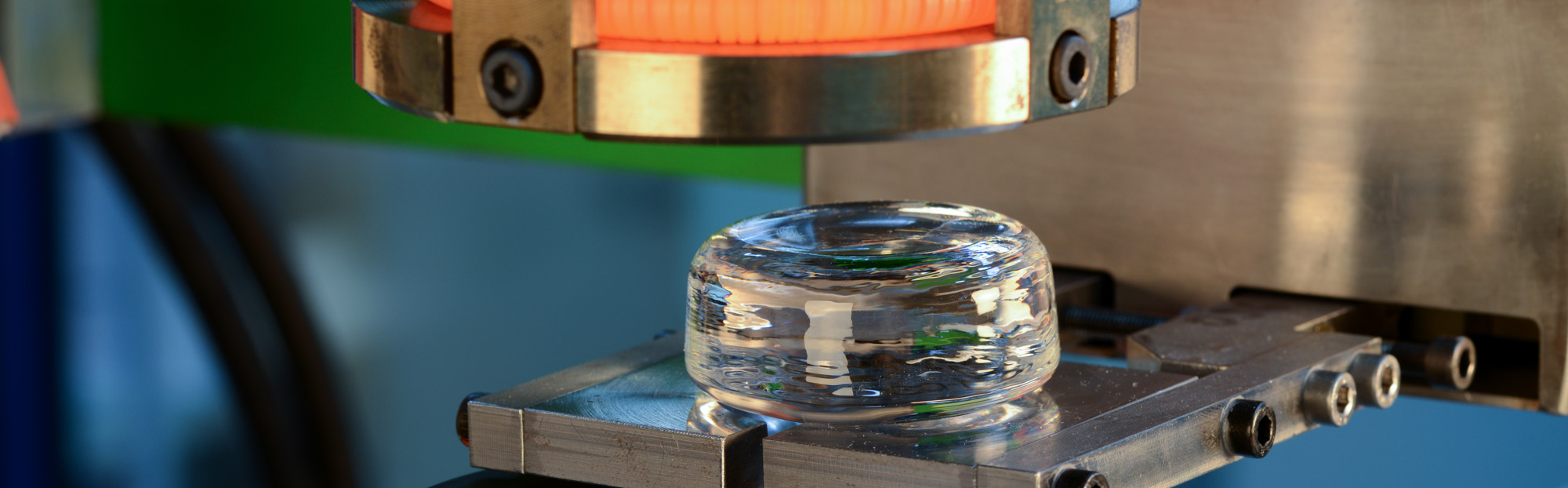

High-precision glass optics with complex shapes are key components of many new products used in a number of industrial sectors. For example, demand for complex yet cost-effective components made of glass is growing in lighting technology, the automotive industry, laser technology and renewable energies.

However, the trend toward increasingly complex geometries coupled with rising cost pressure is presenting companies with major challenges. At Fraunhofer IPT, we research different types of forming for the efficient production of complex geometries. In addition, we are active in the fields of simulation and tool coating.