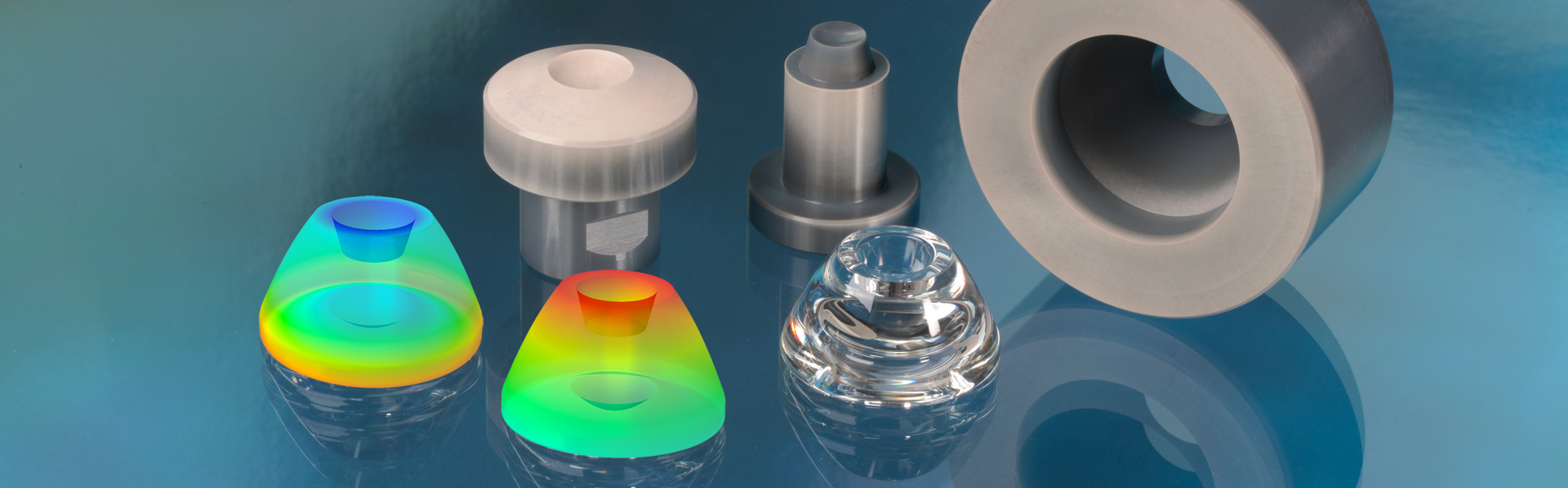

Precision glass molding is a well-established, efficient manufacturing operation used in the replication of glass optics with complex geometries. As a result of thermal and material-related influences, however, it is not uncommon for form deviations which fail to comply with the tolerance specifications, to occur in the glass components. These require subsequent compensation in the form of costly, time-consuming iterative loops in the tool manufacturing operation and in process control.

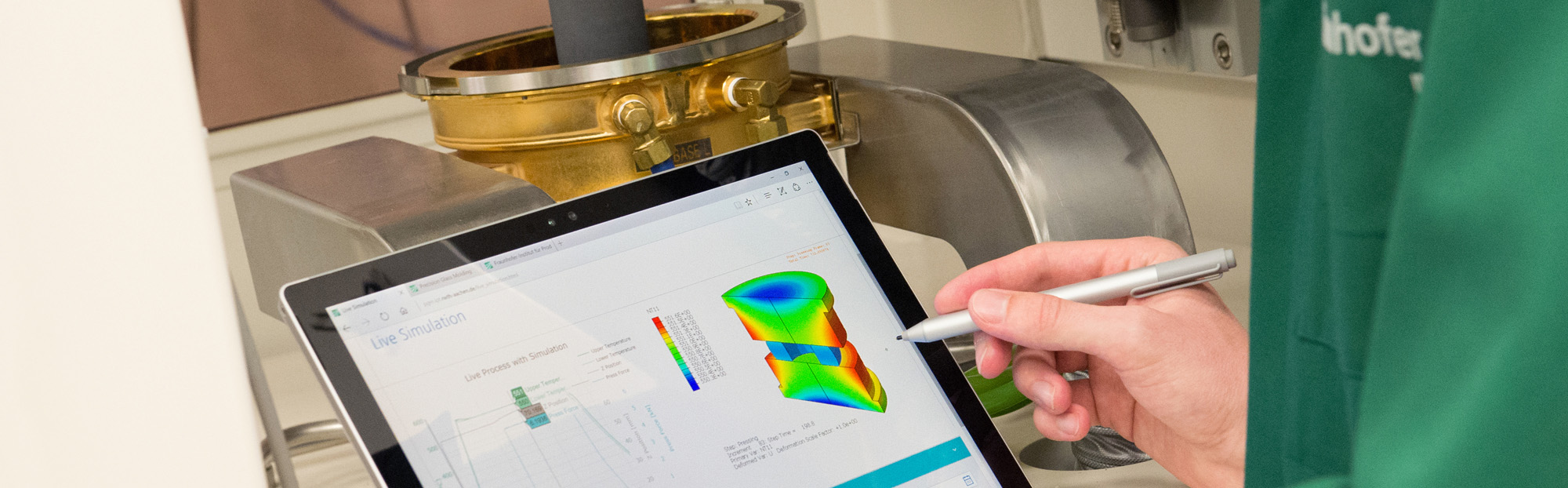

To avoid these laborious re-working cycles, the Fraunhofer IPT has developed a numerical simulation tool for precision glass molding. This simulation tool is the first to permit geometric deviations such as glass shrinkage and optical changes like "Index-drop", to be predicted reliably and the design of the die insert as well as the process control to be modelled realistically before production starts. The outcome of the glass molding process can be determined to within 1 μm accuracy in comparison with the contour measured. Thus the deployment of the simulation tool can significantly reduce the duration and cost of product development.

Comprehensive modelling to predict the outcome of the molding operation

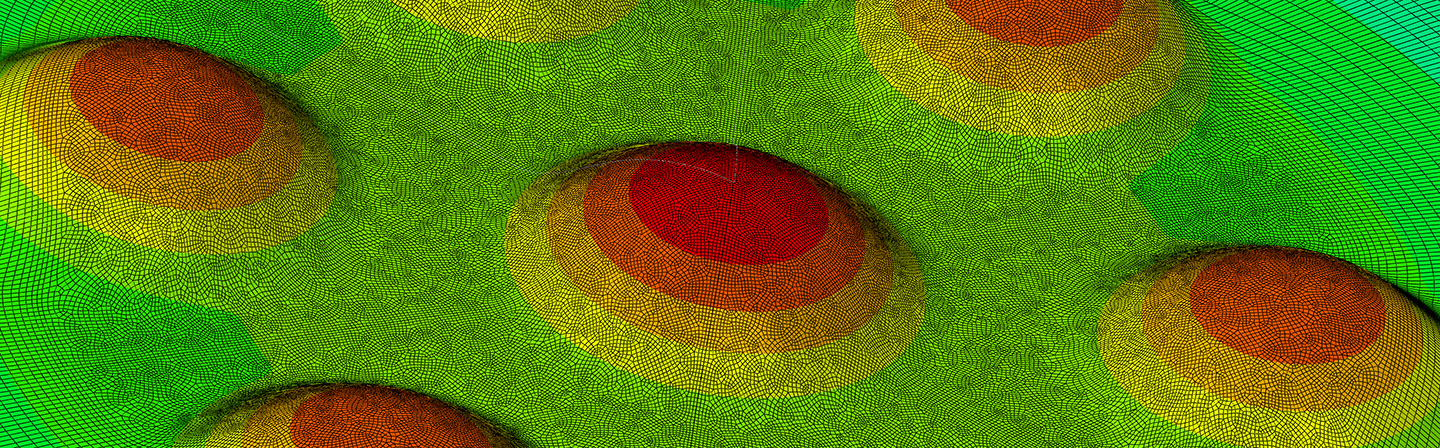

The Fraunhofer IPT has been researching the principles and application of tools to simulate glass molding for around ten years now. In order to take account of all relevant factors which influence the process as part of the simulation, the Fraunhofer IPT has undertaken extensive basic research into the structure of an all-encompassing process model. This includes implementing a visco-elastic deformation and material model as well as a thermal model describing uneven temperature distribution within the glass and the tool. In the course of a number of wide-ranging experiments, the Fraunhofer IPT has acquired precise knowledge of the material properties of optical glass and of the corresponding tool materials.

Simulating non-isothermal glass molding and thin glass

The Fraunhofer IPT has added further glass molding processes to the simulation environment in order to extend the range of applications for which the simulation tool can be used beyond non-isothermal or thin glass molding. One of the customized solutions for the glass forming process offered by the Fraunhofer IPT, is a software tool with a range of diverse functions and a user-friendly interface.

Our service

- Process and tool optimization using a glass molding simulation tool

- Feasibility studies into the simulation of alternative glass molding processes