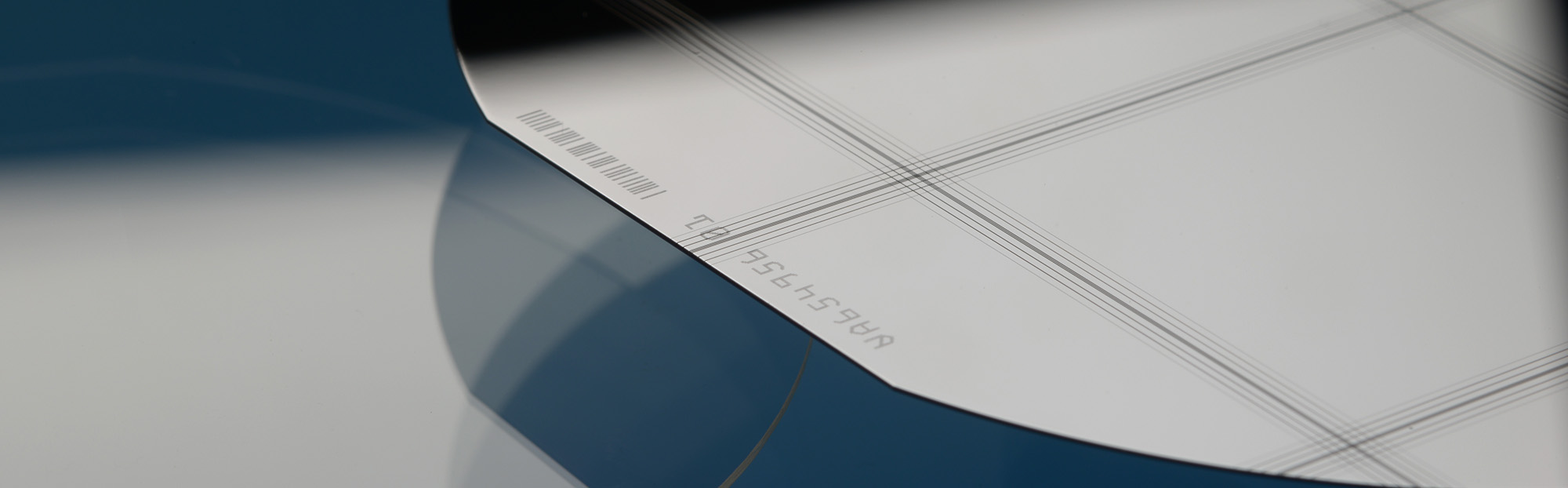

The strong demand for products with ever smaller optical systems presents optics manufacturers with the difficult task that conventional manufacturing technologies such as grinding and polishing can no longer keep pace with batch size and quantity requirements. An efficient alternative to conventional manufacturing technologies is precision glass molding at wafer level.

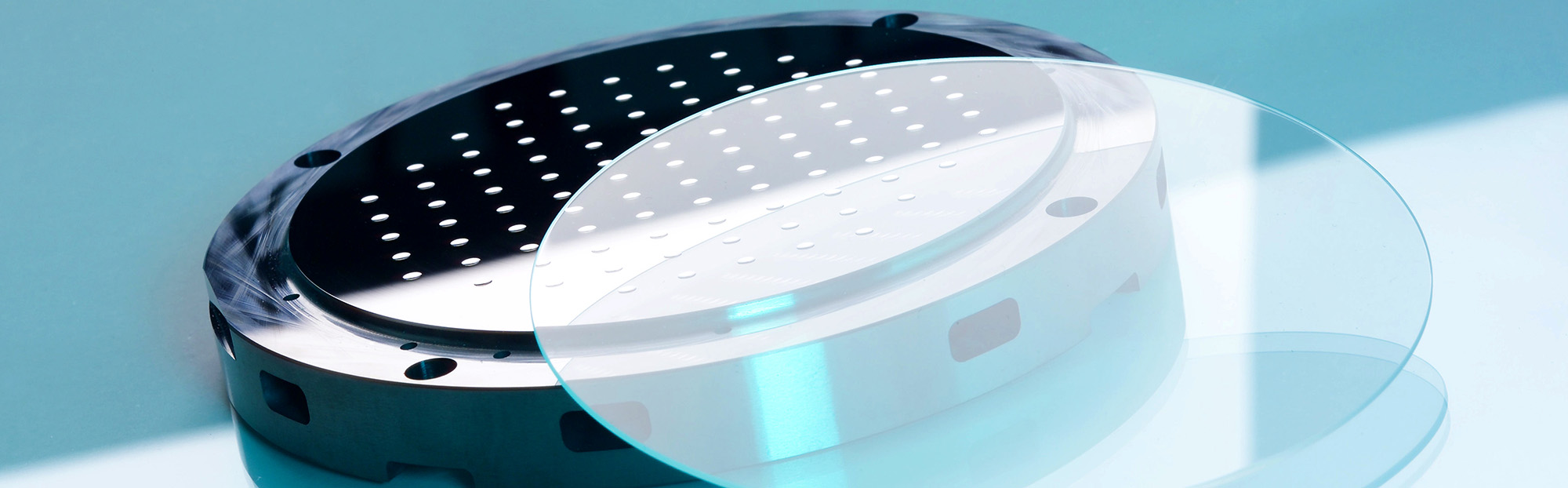

In this process, a polished glass wafer is heated and pressed into the desired shape using ceramic or metallic molding tools. This way, large quantities of high-precision elements can be produced in a single step.

In the manufacture of plastic optics, wafer-based production is already an established process in which a wide variety of micro-optics can be produced on wafers up to 200 mm in size. In the production of glass optics, the technologies are significantly more complex, since the glass and tool material chemical interaction is stronger due to the higher temperatures during the molding process and the tools wear out more quickly.

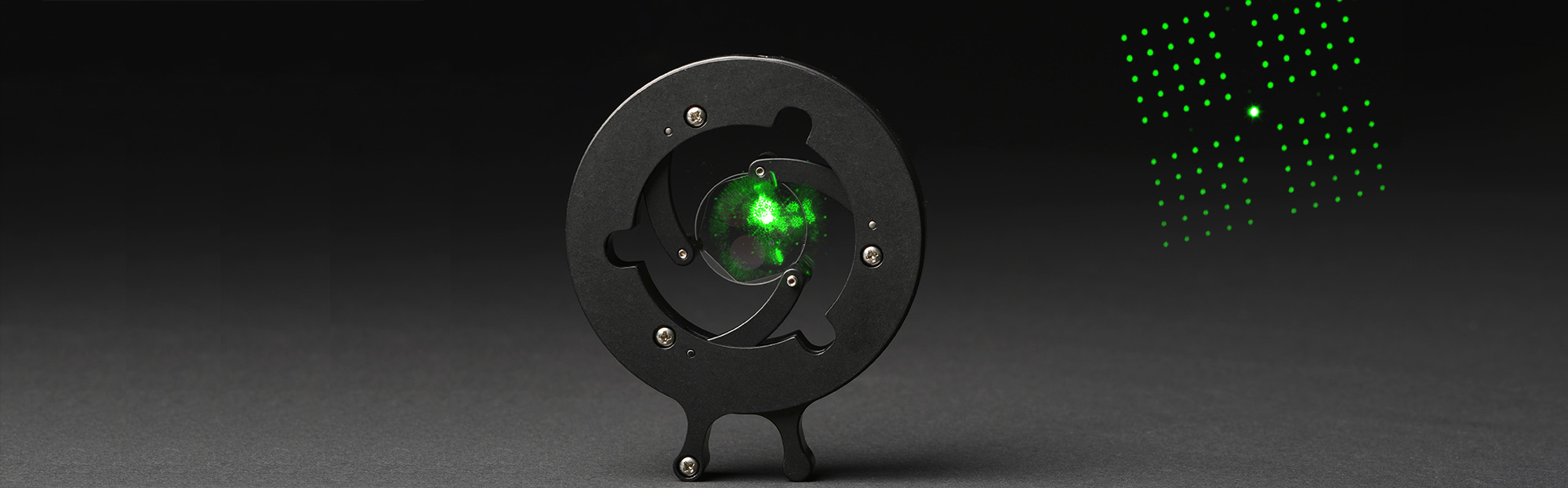

The Fraunhofer IPT analyzes and optimizes the entire process chain, from the simulative design of the tool geometry to the assembly of the optical system, in order to further develop wafer-based manufacturing.

In addition to the wafer-based production of micro-lenses, we form monolithic optics such as lens arrays for beam homogenization on wafer scale. Furthermore, wafer-level glass molding is suitable for the three-dimensional bonding of glass and silicon. Due to the electrical insulation effect of the glass, more compact power electronics can be developed, for example.

Range of services

- Process optimization along the complete process chain

- Predictive process design via simulation

- Layout and design of the molding tools

- Production of large-area, high-precision mold tools

- Implementation of systematic test series and prototyping

- Automated optics assembly