Modern micromanipulation and measuring techniques allow for the highly accurate positioning of smallest components and optics within a few nanometers. However, the bonding process sets limits to the repeatability which can be achieved in industrial and automated production of precision systems. We have acquired in-depth expertise in the adhesion process in the course of numerous projects relating to prototype assembly and fully chained assembly processes. We apply this knowledge to control the properties of the adhesives and to develop robust bonding processes for automated precision assembly.

Modules for integrated process optimization

In automated micro-assembly, controlled metering of the adhesive is essential to the quality of reproducible bonding processes. To ensure that the adhesive is dispensed with precision, the Fraunhofer IPT has developed a characterization and calibration station which can be integrated in existing equipment to determine the volume of individual drops of adhesive as they fall, down to a droplet volume of only a few picoliters. Additionally, the position of the dispenser can be determined with an accuracy level of only a few micrometers. The correct amount of adhesive can thus be delivered to exactly the right point.

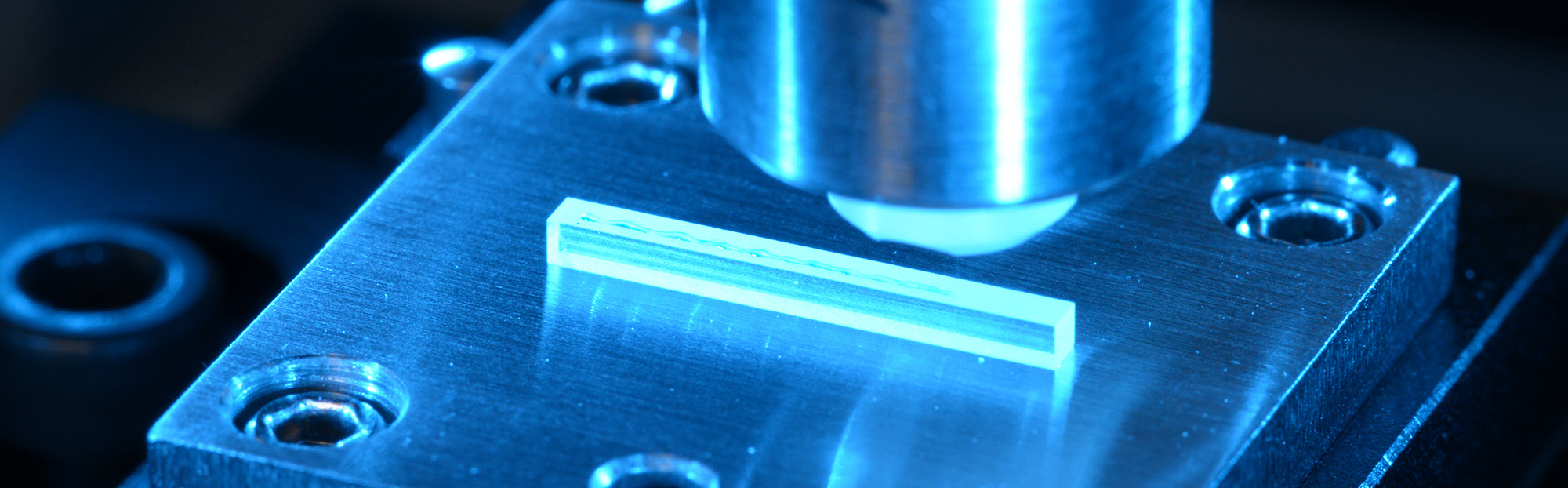

Alongside high-precision metering and positioning, curing is one of the key elements in ensuring reproducible joints with UV-hardening adhesives. To this end, the Fraunhofer IPT integrates UV-sources inside a micromanipulator. There are two benefits of this. It permits the UV radiation to be dispensed accurately in accordance with the application in hand and ensures that the adhesive is cured completely. Consequently, the effects of any misalignment are made more manageable at the same time.

Decision-making tool to help select the most suitable adhesive

Different manufacturers of adhesives use various measuring methods to determine adhesive shrinkage. As a result, it is impossible to compare shrinkage on the basis of the data provided by the manufacturers. The Fraunhofer IPT therefore analyzes samples of adhesive itself: We measure adhesive shrinkage in linear and volumetric operations, record the measurements in an internal database and compare them. Our policy of measuring the adhesive shrinkage ourselves allows us to identify the most suitable adhesive for each application. We will be happy to measure your sample – because knowledge as to the behavior of the material used makes it manageable and permits precision assembly.

Our Services

- Characterizing adhesive shrinkage

- Developing bonding processes including compensation for shrinkage

- Analyzing processes and improving existing assembly processes

- Integrating dispensing and curing equipment

- Designing, producing and integrating customized UV sources

- Developing and automated joining process

- Product design for bonding