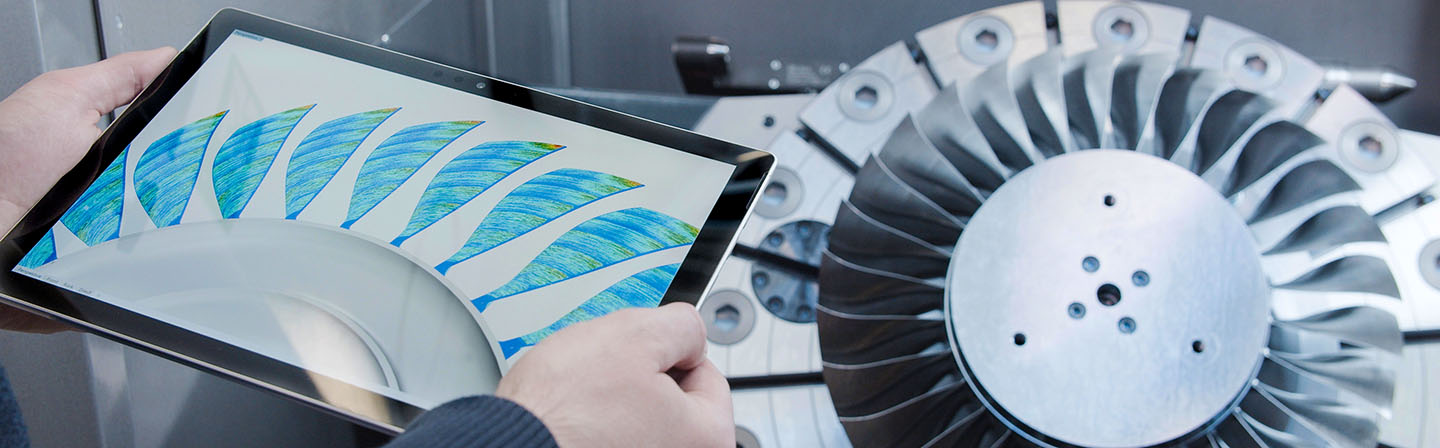

Fraunhofer IPT develops machines, modules, tool technology, manufacturing processes and process chains for cutting with a defined and undefined cutting edge. For turning, milling and grinding, we not only lay out manufacturing equipment and process design, but also gain valuable insights through real-time data acquisition during production, which we incorporate into our project partners' prototype manufacturing. With a sound scientific background and many years of practical experience from a large number of research and development projects on behalf of industry, we are now increasingly relying on digitalization technologies and plant networking in our modern machinery to ensure the competitiveness of our customers and research partners.

State-of-the-art machinery and individual further developments

To ensure that extreme precision and stable processes can be reliably achieved and industrial production can be flexibly designed, we optimize existing machines and systems and produce prototypes of new machine concepts and individual modules for machining. We are continuously expanding our machinery in line with Industry 4.0 norms, integrating sensors, networking machines and components, and working with artificial intelligence and machine learning algorithms to further improve the results of machining production processes.

Broad technology portfolio for diverse fields of application

We focus our work on simultaneous multi-axis milling and turning of geometrically demanding components made of superalloys, high-hardness steels, lightweight and composite materials, and special materials. Our technology portfolio also includes automated fine machining, diamond cutting, ultra-precise grinding, polishing, and micro- and nanostructuring. For high accuracy and the smallest tolerances in the range of a few micro- and nanometers, we develop special machines and systems for high-precision applications. Typical fields of application are found, for example, in turbomachinery, aircraft and tool making as well as in medical technology.