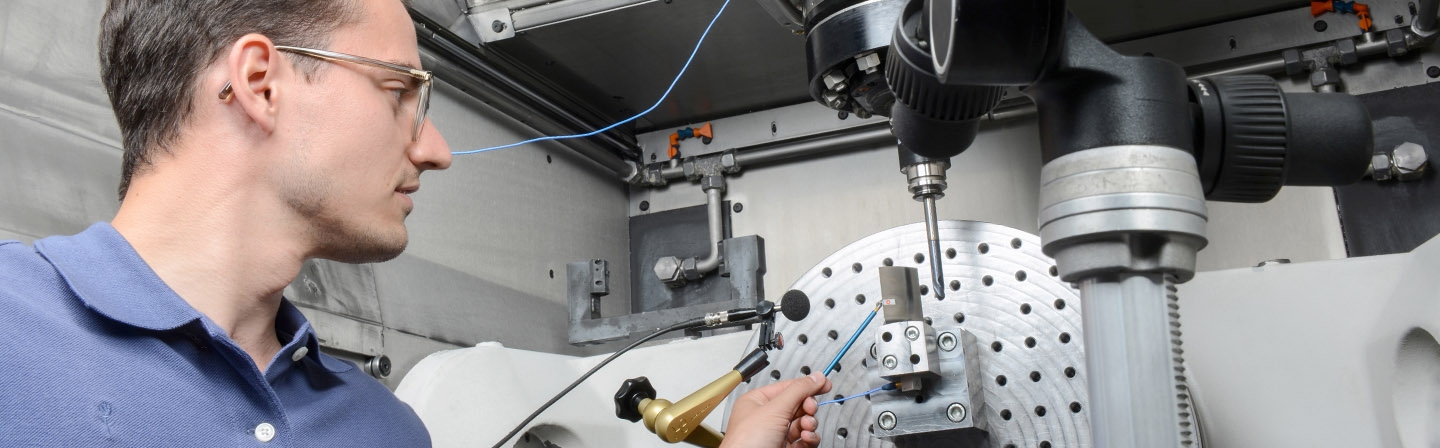

Fraunhofer IPT develops technologies and application-oriented solutions for cutting along the entire process chain – from process design and real-time data acquisition during production to consulting and prototype production. We handle research and development projects comprehensively and purposefully with technological knowledge, system expertise and our modern machinery; in doing so, we use the possibilities of digitalization to deepen process understanding and ensure competitiveness.

Our topics are in particular simultaneous multi-axis milling and the turning of geometrically demanding components made of superalloys, high-hardness steels, lightweight and composite materials as well as special materials. Typical applications come from turbomachinery, aircraft and tool making as well as medical technology.

dPart® – Framework for high-performance cutting

The dPart® digital framework enables us to create complete and data-consistent Digital Twins along the entire value chain. For planning, production, and quality assurance, we are thus creating the possibility of a cross-interface digital ecosystem for metal processing.

We are continuously developing dPart® in collaboration with the Manufacturing Technology Institute – MTI of RWTH Aachen University. We are supported by software and hardware suppliers for manufacturing systems and plants as well as edge and cloud providers who align their systems with our developments. Interested companies from the metalworking industry, mechanical and plant engineering, and providers or suppliers of digital infrastructures are welcome to collaborate with us!