Durable tools and robust optical components reduce costs and minimize downtime. Our coatings extend service life, lower friction, and protect against environmental influences – ensuring efficient and sustainable production processes.

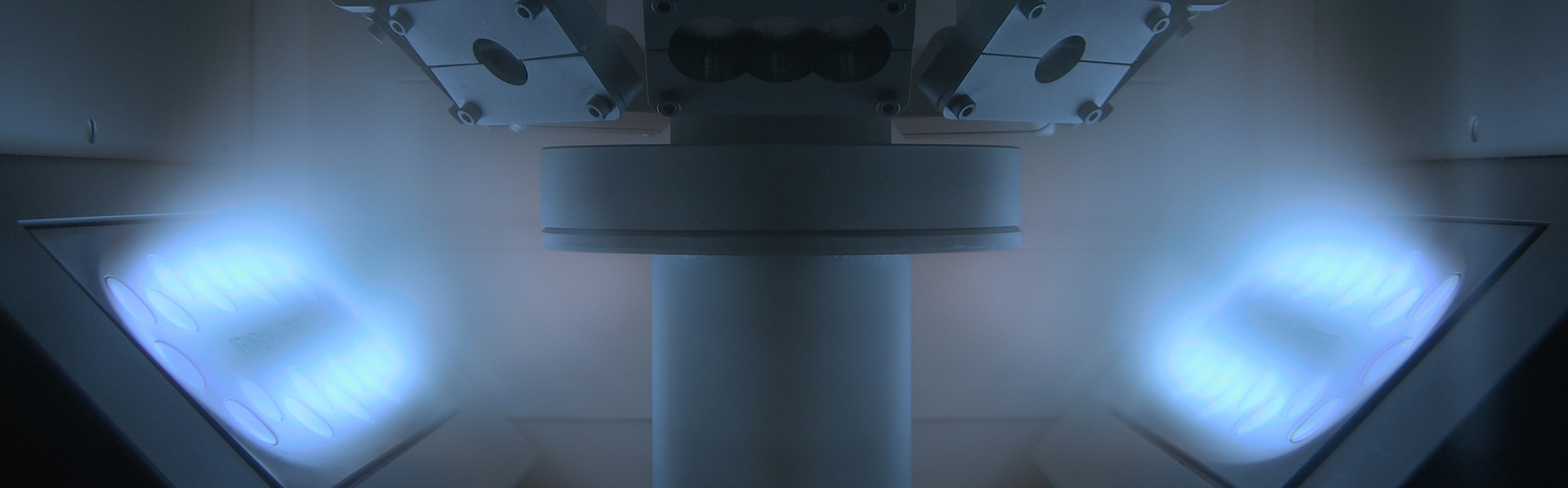

Using state-of-the-art coating technologies, we develop tailor-made solutions for demanding applications –from high-performance molding tools to sensitive optical components.

We focus on precisely adapting coating systems to specific stress factors. By analyzing failure mechanisms, we systematically optimize coatings for maximum performance.

Our services at a glance

We offer customized solutions designed to meet your specific requirements:

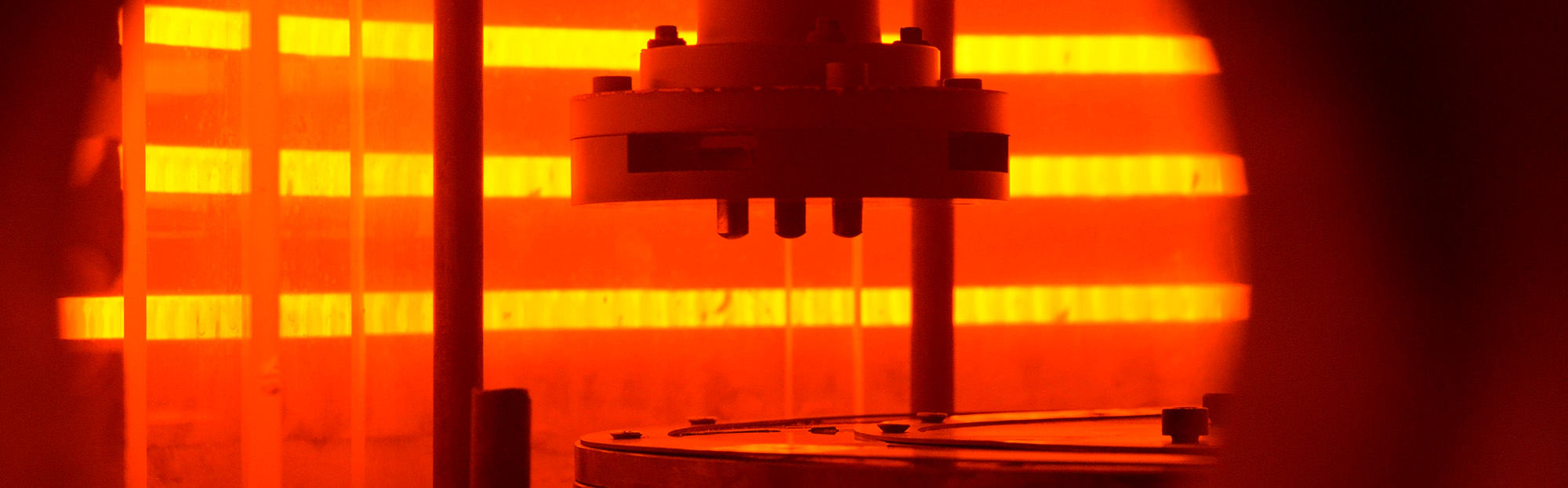

- Analysis and characterization of wear-resistant coatings for glass forming and plastic injection molding tools

- Development of functional coatings tailored to your processes—improving service life, reducing downtime, and enhancing process stability and cost efficiency

- Service life testing of new coatings