Optical coherence tomography (OCT) is a non-invasive imaging technique that can be used to tomographically examine transparent and semitransparent materials. The operating principle of OCT is similar to that of ultrasound imaging. However, unlike ultrasound, OCT works with light rather than sound waves. OCT provides depth-resolved cross-sectional images and volumetric images with a penetration depth of several millimeters and a resolving power in the single-digit micrometer range – about ten times better than ultrasound.

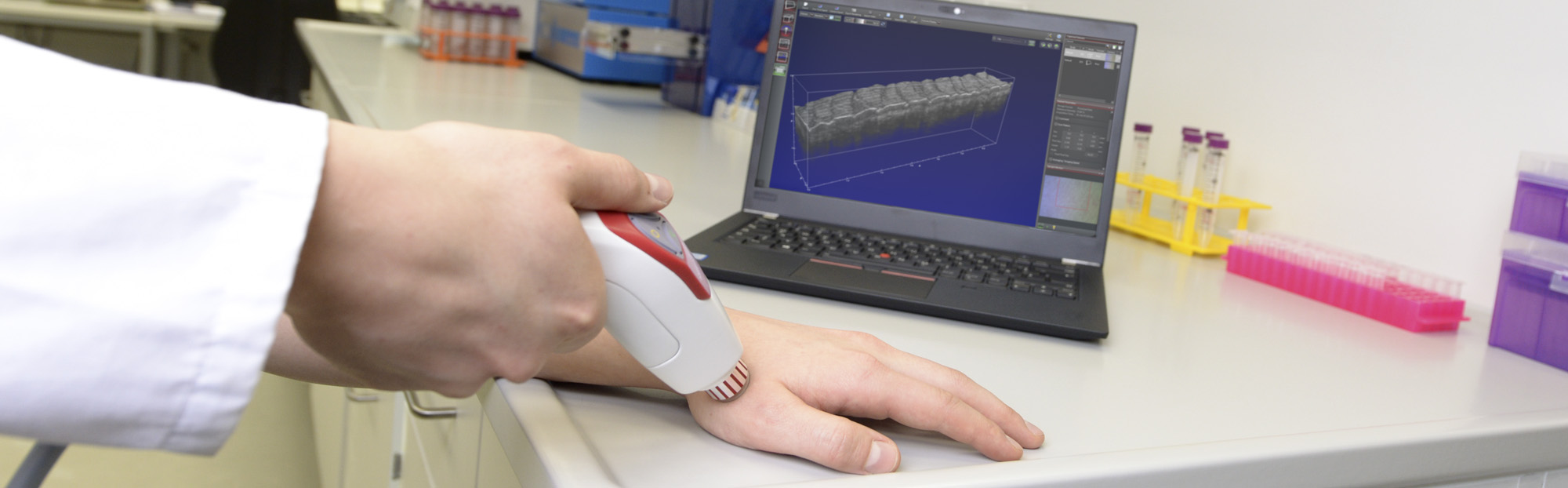

OCT has so far been used mainly in non-contact biomedical diagnostics. The measurement method is based on short-coherent interferometry and allows the diagnosis of the fundus of the eye within seconds using high-resolution cross-sectional images or the volumetric imaging and differentiation of tissue layers. The advantages of OCT can also be exploited in numerous industrial production applications.

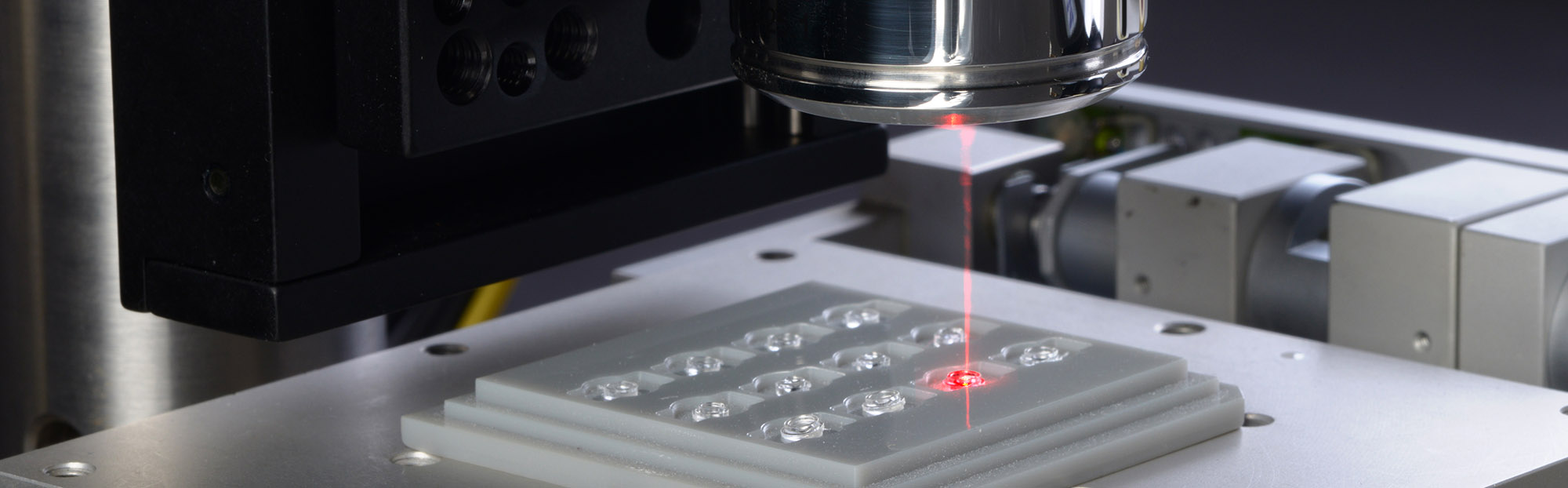

In numerous research and industrial projects, Fraunhofer IPT has explored and developed the potential of OCT beyond biomedical diagnostics: Whether it is the high-resolution measurement of thin layers in the printing industry or the in-line integration of OCT for coaxial process monitoring of laser processes. In (semi-)transparent materials such as plastics, films or paints, OCT allows insight into deeper layers and thus opens up the inspection of application quantities as well as the detection of air inclusions or other defects. In metal processing, surface features and shape deviations can be detected during the process.

Our services at a glance

- Development of individual OCT systems

- Implementation of individual signal and image processing algorithms

- System integration

- Sensor system automation