A decisive criterion for the function of optical systems is the shape of the optical functional surfaces and their position relative to each other. However, standard measurement methods on the market do not yet offer enough possibilities for characterizing polymer optics with small apertures for complex geometries, such as those used for camera lenses in mobile phones, endoscopes or car sensors.

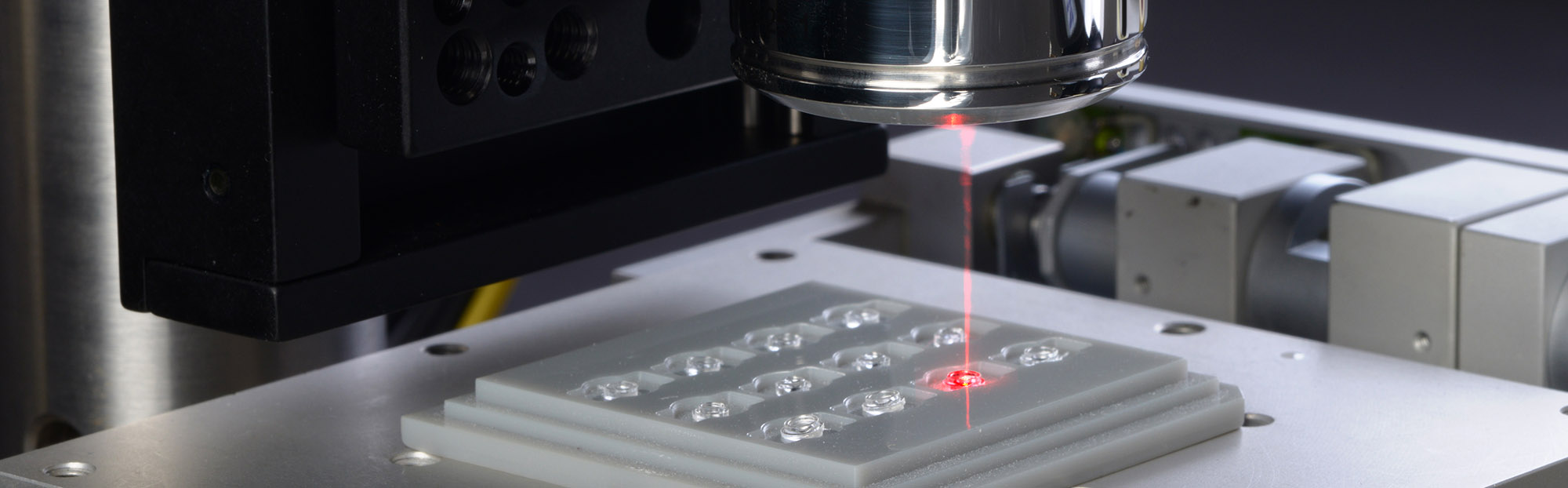

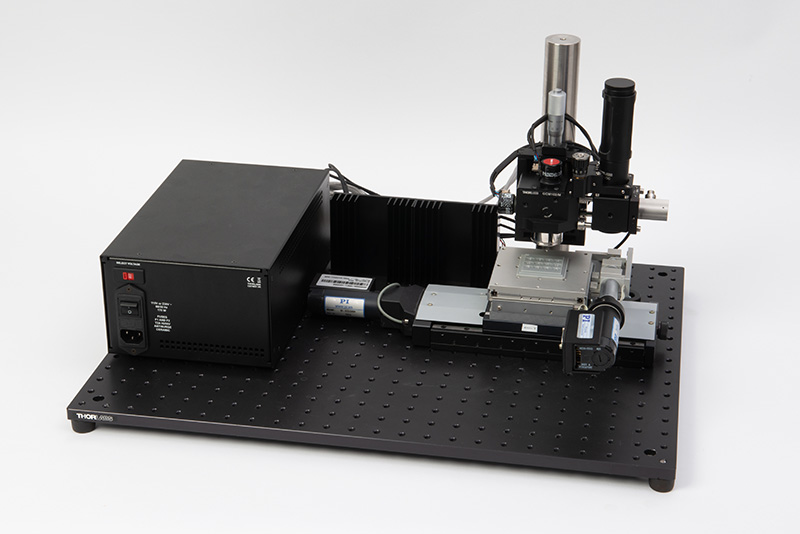

The Fraunhofer IPT is therefore developing a tomographic method for testing polymer optics with a small aperture: It is based on optical coherence tomography (OCT) and enables non-destructive measurement of the components.

With only one measurement, both functional surfaces are captured simultaneously. This not only allows the characterization of surfaces. The centring of the functional surfaces to each other can also be checked. Due to the high variability of the method regarding the geometry of the test specimen, both spherical and aspherical lenses as well as free-form surfaces can be tested. In perspective, the measuring method also offers the potential for inline integration into existing optical production lines.

Our service

- Development of OCT measuring systems for tomographic optical testing

- Testing of plastic spheres and aspheres with small aperture

- Inspection of freeform surfaces