The mass assembly of microsystems requires automated handling and alignment of the components. With its wealth of experience for industry-ready solutions, Fraunhofer IPT draws on existing components from micro assembly, as well as in-house developments, to efficiently develop solutions for automated assembly.

Automated assembly systems for medium to large quantities

We develop and test prototypes of individual production systems and machine components for the automated assembly of miniaturized laser systems, cameras and optical sensors in medium to large quantities. Our expertise ranges from individual technologies to the development of complete solutions, which we bring to market hand in hand with industrial cooperation partners.

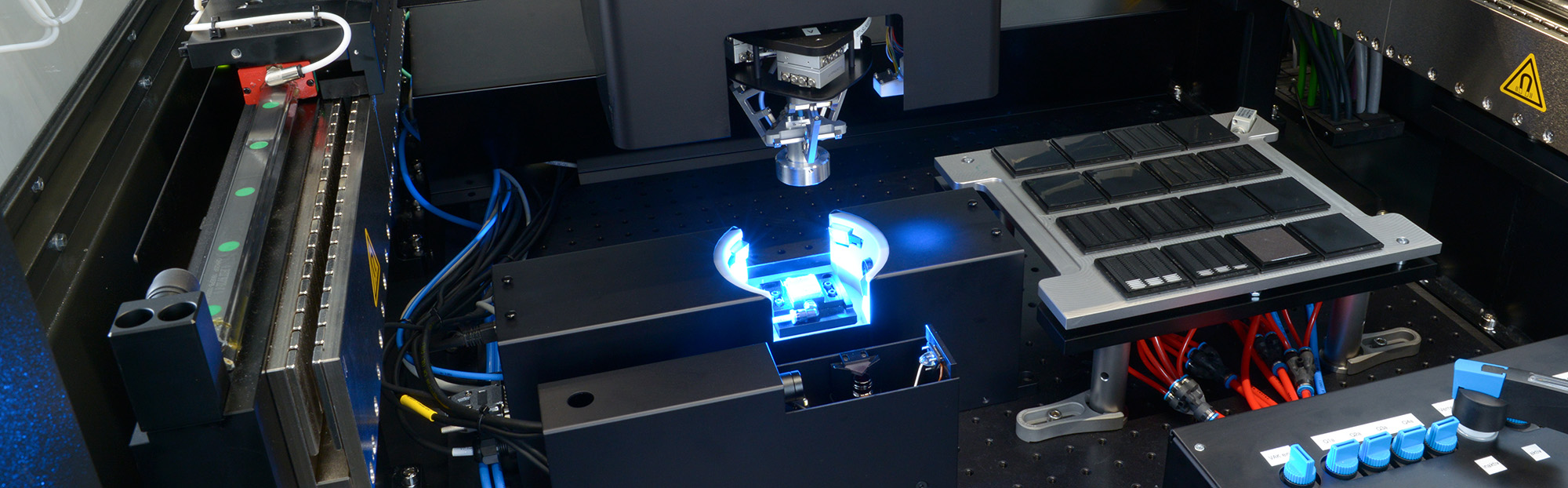

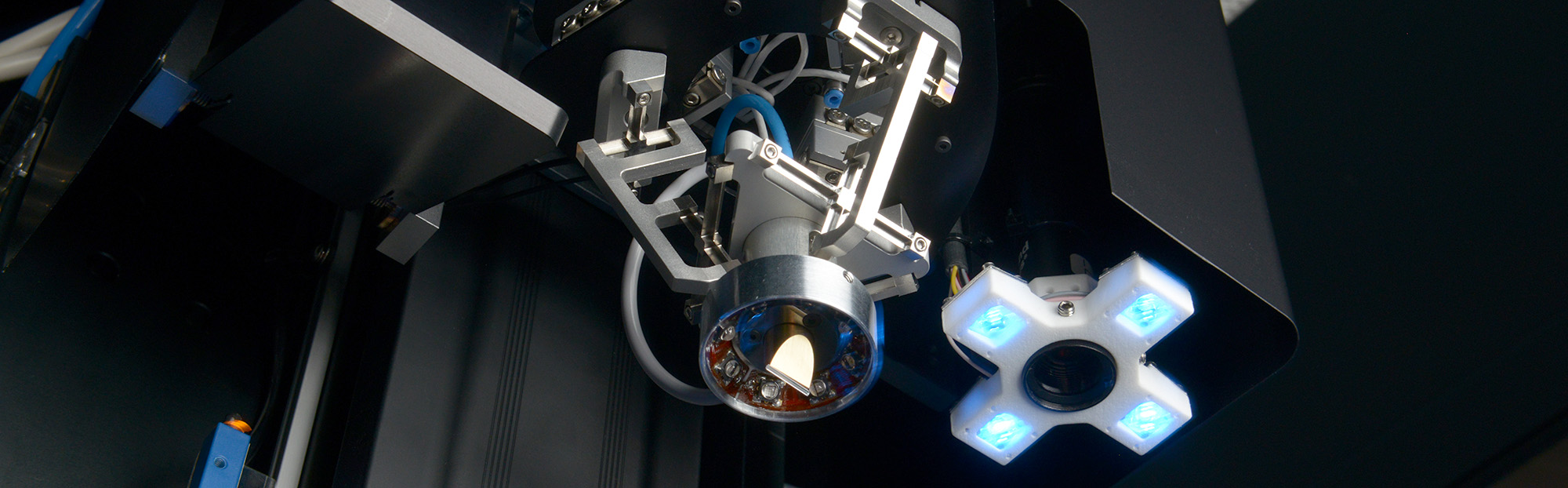

Modular system for precision and micro assembly

To automate assembly, we use a modular micro assembly platform consisting of standard modules and software modules for sensor-based process control and networking within an Industry 4.0 environment. One of these standard modules is the C6 micromanipulator, which we have provided with an expandable user interface and which efficiently supports individual micro assembly systems.

We will be happy to check the feasibility of automation for your assembly tasks and develop the necessary machine components and processes. With our development and sales partners, we create a sustainable solution with the usual service. Machine safety, radiation protection and CE certification are a matter of course for us.