Microscopic structures on a large surface

For the production of microstructures, there are various machining processes that can be used to functionalize surfaces for optical, microfluidic or medical technology applications. For example, they can produce mold inserts for large-area retroreflectors or lab-on-a-disc platforms.

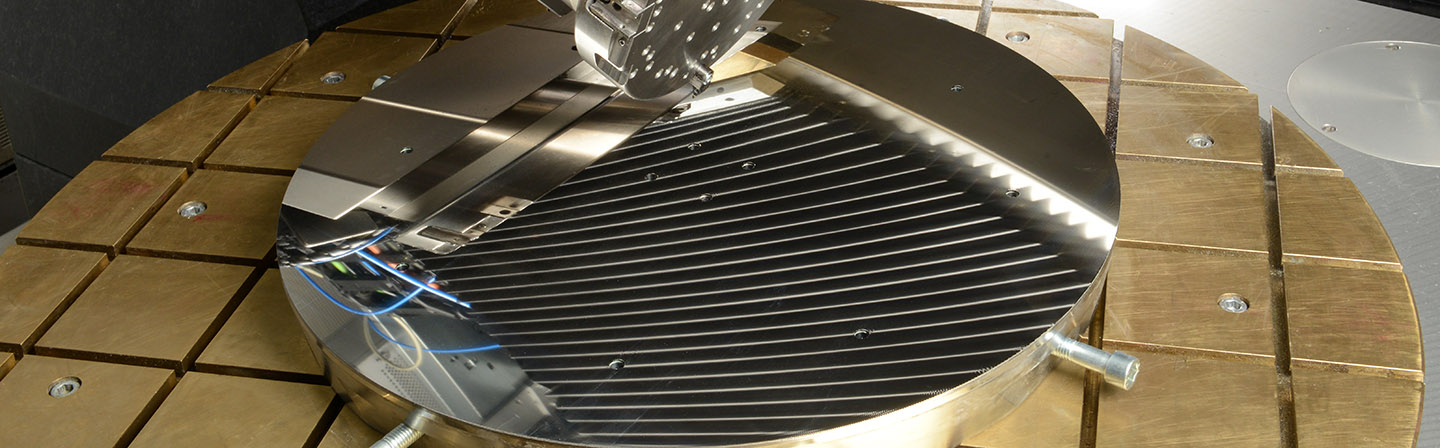

Special purpose machine from Fraunhofer IPT: Planing machine creates small structures on a large area

In most cases, the size of the machining area on ultra-precision machines is severely limited by the machine kinematics. At Fraunhofer IPT, we have developed a machine concept that allows surfaces up to 800 mm x 1200 mm to be machined: Fraunhofer IPT's ultra-precision planer is a hydrostatic ultra-precision machine with a granite bed and portal. It has three linear axes (x, y, z) and a rotary machine table with a rotary axis (c). In the future, it will be upgraded with another a axis. Only a few production machines of this type have an axis system with such large traverse paths.

Planing and fly-cutting of non-ferrous metals using diamond tools for high-precision applications.

Planing and fly-cutting processes are used to machine non-ferrous materials such as copper, aluminum, nickel silver and nickel phosphorus with a monocrystalline diamond. Different structures can thus be introduced into the surface of the workpiece. So-called V-grooves are often produced for optical applications, but other structures, such as pyramids, can also be manufactured using fly-cut or planing processes. By using special contour tools, cylindrical or non-cylindrical trapezoidal grooves can also be cut.