There is a direct relation between the precision of the machine tool and the quality of the work piece, which is why calibrating machine tools is essential – both for manufacturers of machines as well as for users. In addition to linear axis errors, like positioning and straightness, many other imprecisions can arise when working with 5-axis machine tools. If at all possible, these errors can only be eliminated with a significant amount of effort due to the great complexity of the rotational and linear axes. Although careful calibration is absolutely necessary in order to ensure the quality of the work pieces, the high costs associated with it often cause companies to skip it in a misguided attempt to save money.

Increase machine tool precision with the R test

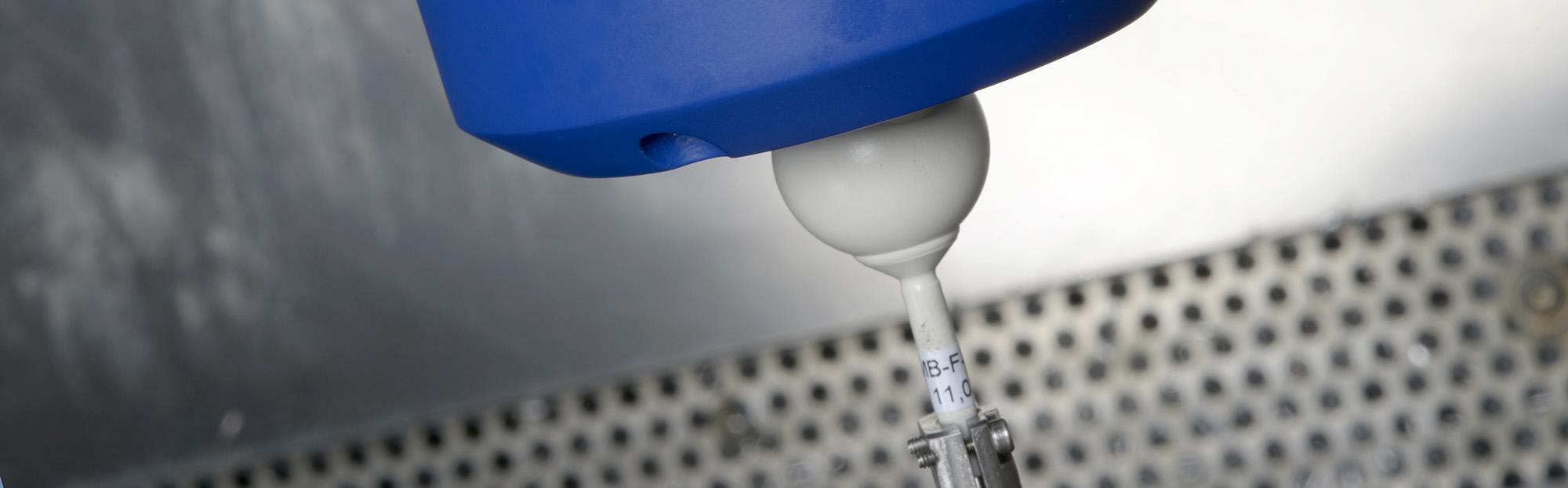

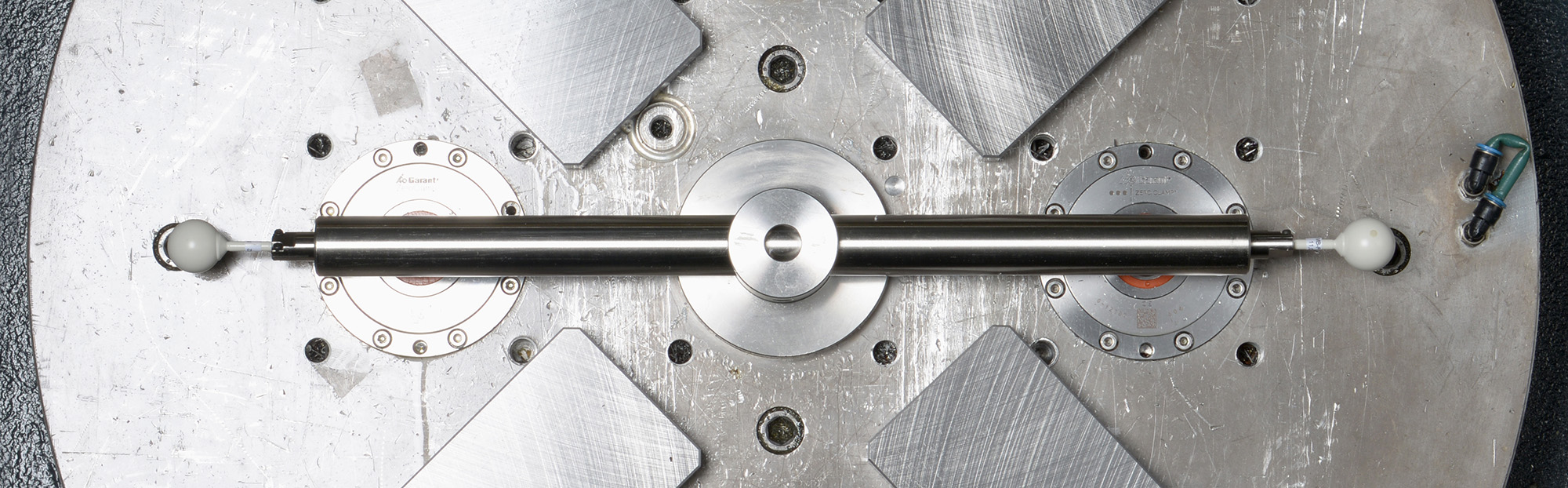

The Fraunhofer IPT has thus set out to develop an efficient low-cost solution that makes it possible to quickly and easily identify all the relevant geometrical deviations of 5-axis machine tools. To do so, we utilize the R-test (a.k.a. chase-the-ball calibration), in which a 3D distance sensor is mounted on the tool holder and a calibrated ball is mounted on the machine table. The displacement of the ball relative to the sensor is measured during synchronized movements, enabling the identification of all machine errors at once. We employ various methods to compensate identified errors according to each individual case.

Push-button measurement process

This new method makes it possible to fully calibrate a 5-axis machine tool at a maximum time of two hours. Our special calibration software enables push-button calibration. Complete automation is possible thanks to a wireless sensor that serves as the sole measuring device. The new calibration process thus represents a fast, affordable and automatable alternative to current processes.

An overview of the most important advantages of our calibration process

- Direct measurement and optimization of 5-axis precision

- A single tool for measuring all deviations

- Enormous time savings compared to current processes

- Easy automation and tight integration into your machine