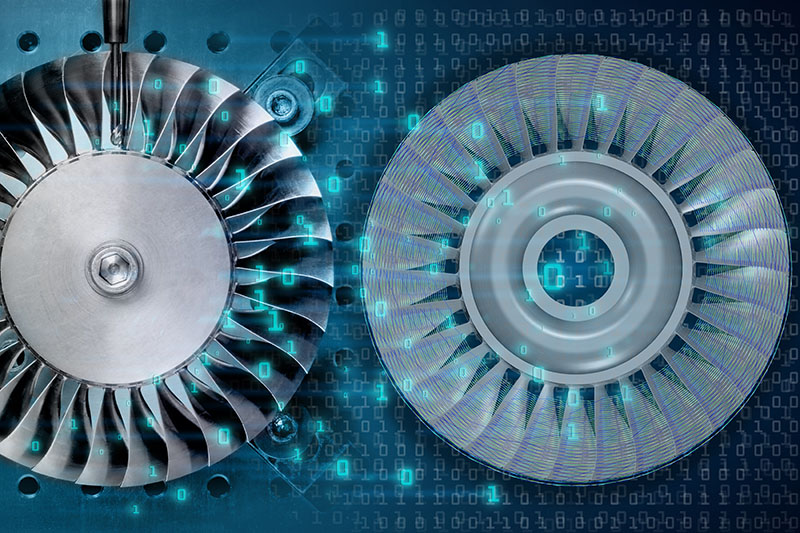

We enable the digital twin to be used in production: product data, supplemented by models, operating and process data, provides a comprehensive and dynamic image of a real product. It creates the basis for carrying out retrospective analyses as well as making statements about the future of a product.

By enriching the digital twin with more and more current (measurement) data, a detailed digital image is created that enables even more reliable statements and forecasts. For example, services for tracking products can be developed, usage analyses can be carried out or predictive statements can be made for better and more timely maintenance.

Industry and research - ready for use with the digital twin in production

Fraunhofer IPT is working on numerous projects to further develop the digital twin in production and make it usable for a variety of products and tasks in different industries.

We not only support companies in identifying the right tools and suitable sensor technology for data collection: With powerful methodology, suitable analysis tools, our technological expertise and our own high-performance IT and production infrastructure, we enable you to collect, secure, process and analyze huge amounts of data and prepare it to derive suitable measures.

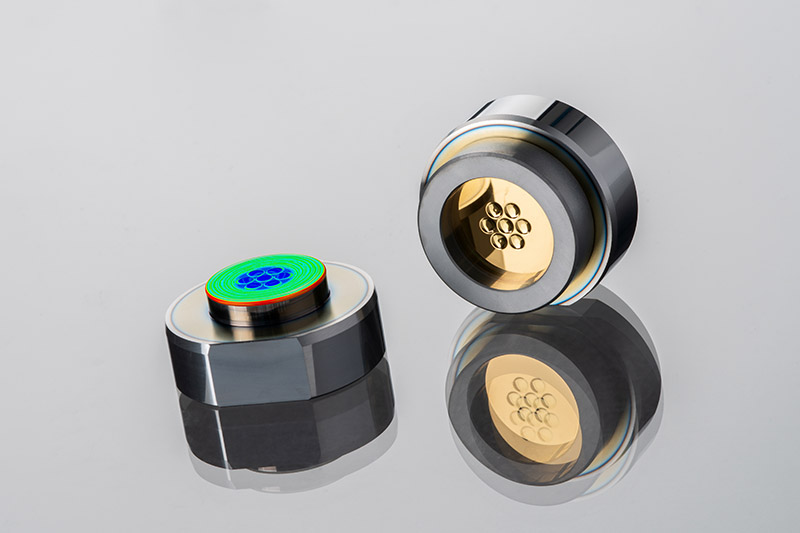

From knowledge to benefits: Digitaler Zwilling.NRW competence center

With the DigitalerZwilling.NRW competence center, the Fraunhofer IPT is building a state-of-the-art infrastructure together with four research partners and nine associated partners from industry, business and educational institutions: The aim is to offer companies, research institutions and schools simple, interactive access to digital twin technology and to make the technology tangible. From the beginning of 2028, inquisitive minds will be able to discover the benefits of this technology for themselves at learning stations using digital twins of real components and production processes as well as in application-related scenarios and simulations. Understanding this will form the basis for their own innovative solutions.