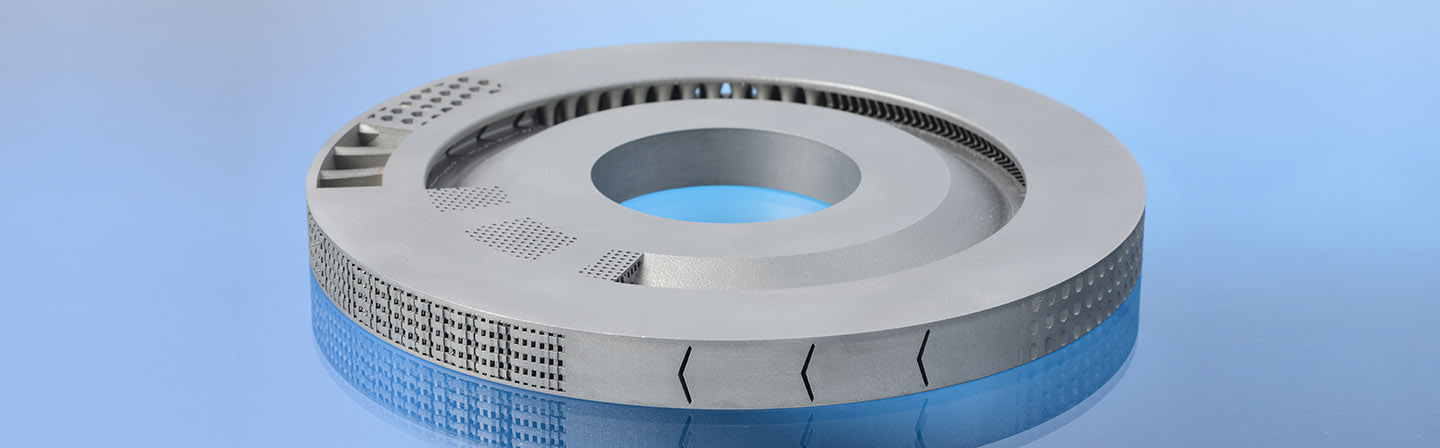

Additively manufactured grinding wheel

In a design study, concepts for additively manufactured grinding wheels were developed and implemented that enable the targeted supply of cooling lubricant through the grinding wheel body into the contact zone between tool and workpiece. Effective supply of the coolant prevents the thermal damage to the material known as "grinding burn". The design concept has been successfulmanufactured in initial tests.

Additive Manufacturing processes such as Laser Powder Bed Fusion (LPBF) expand the freedom to design and produce components for nearly every industrial sector. This makes it possible to easily and reliably manufacture geometric shapes that cannot be produced using conventional manufacturing processes, or only at great expense. This new design freedom can be used profitably in the area of tool technology, for example, to optimize weight and selectively guide gases or liquids.

Design concept enables targeted supply of cooling lubricant

Effective supply of the coolant prevents the thermal damage to the material known as "grinding burn". Sufficient cooling of the contact zone is not always ensured by the lateral coolant supply, however, particularly in the case of wide grinding wheels or the production of grooves. Within part of a design study, the Fraunhofer IPT has developed concepts that can selectively supply cooling lubricant through the grinding wheel body into the contact zone between tool and workpiece.

As a demonstrator, a grinding wheel body consisting of seven segments was additively manufactured. Each segment incorporates a different design for channeling the coolant. The designs include different channel concepts from stable columns to fine lattice structures. The internal structures were printed without support structures. In the next steps, the process will be further elaborated in terms of manufacturing technology.

Use of additive technologies planned for the production of various tools

Additive Manufacturing processes open up a great variety of possibilities that are not limited to grinding wheels for tool technology. For this reason, the Fraunhofer IPT is planning to expand the use of additive manufacturing to redesign and improve various tools – both for conventional manufacturing processes such as grinding and milling, and for non-conventional processes such as electrochemical machining (ECM). By integrating additive processes into production chains, the Fraunhofer IPT aims to help increase the performance of tools and improve their application behavior.