Hydrogen is a clean and renewable energy storage medium: When hydrogen reacts with oxygen, only water is produced and no harmful emissions are generated, as is the case when fossil fuels are burned. Hydrogen can therefore help reduce dependence on fossil fuels and provide a sustainable energy supply. The necessary components for this are fuel cells and electrolyzers.

To ensure that the growing market demand can be met quickly, our research is helping the automotive, aerospace, mobility and energy sectors to overcome the existing hurdles to the widespread use of hydrogen technologies:

Reduce manufacturing costs and unit prices

Electrolyzers and fuel cells, and thus hydrogen production and use, are still too expensive compared to internal combustion engines and fossil fuels. If the manufacturing processes for the components can be automated and transferred to series production, the unit prices of fuel cells and electrolyzers can be reduced and, in addition, an increasing demand can be satisfied.

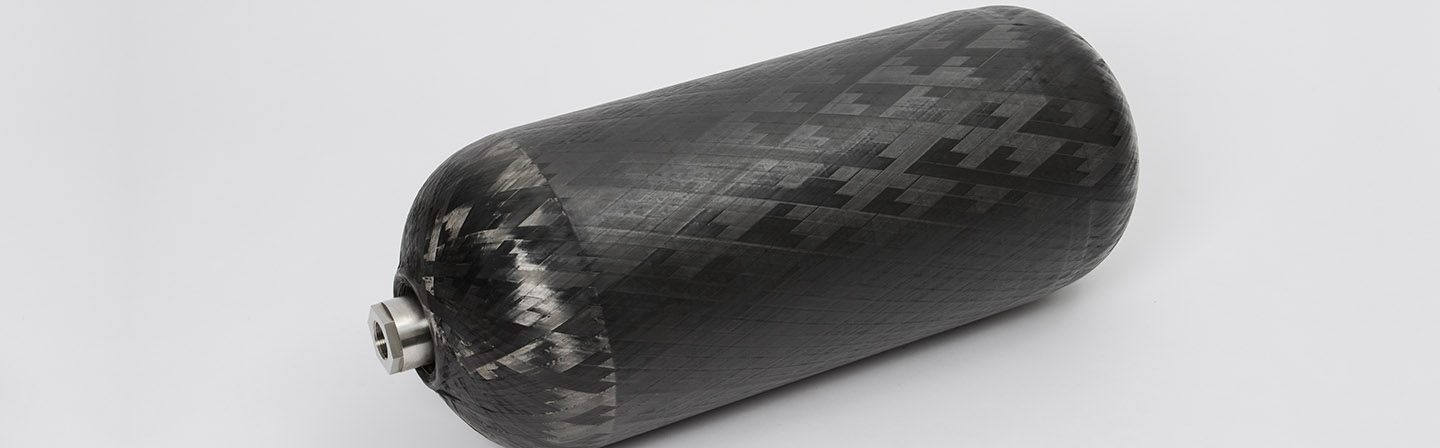

Making transport and storage safe

The necessary infrastructure for transporting and storing hydrogen is also not yet available nationwide. In addition, hydrogen carries a high risk of explosion - a challenge for safe handling and storage. This is where we come in with hydrogen pressure tanks made of fiber-reinforced plastics that can withstand enormous pressure and are corrosion-resistant despite their low weight.

Developing production technology for efficient energy conversion

Compared with other energy sources, the efficiency of hydrogen technologies is still too low to allow them to be used cost-effectively everywhere. Together with our partners from industry and research, we are therefore continuing to develop components and the processes for their manufacture at full speed. We use our understanding of processes and our expertise in special-purpose machine construction to answer the ever-changing production engineering questions that this raises with regard to new materials and precise manufacturing.

Ensuring safety standards through complete documentation of manufacturing processes

In aviation in particular, all components are subject to extremely high safety standards. We can achieve seamless documentation of manufacturing by using digital twins.

Improving sustainability and quality with manufacturing data

To further develop hydrogen into a sustainable yet economical alternative for transportation and energy supply, we are focusing on digitizing production. By simulating manufacturing steps, storing and evaluating process data, we optimize production and can thus reduce material usage, minimize waste and improve product quality.