The mechanical properties of glass and carbon fiber reinforced plastics (FRP) make these particularly suitable for the manufacturing of lightweight, stable and corrosion-resistant components. New methods of collecting and utilizing production data combined with virtual process modelling are crucial for the large scale manufacturing of this composite components. The Fraunhofer IPT develops automated systems and processes for these materials. One example is the laser-assisted tape winding process. Thus, lightweight pipes and pressure vessels made of FRP for oil and gas exploration, for use in the energy sector or in the automotive industry can be produced efficiently and flexibly.

The tape winding process has paved the way for a wide range of products

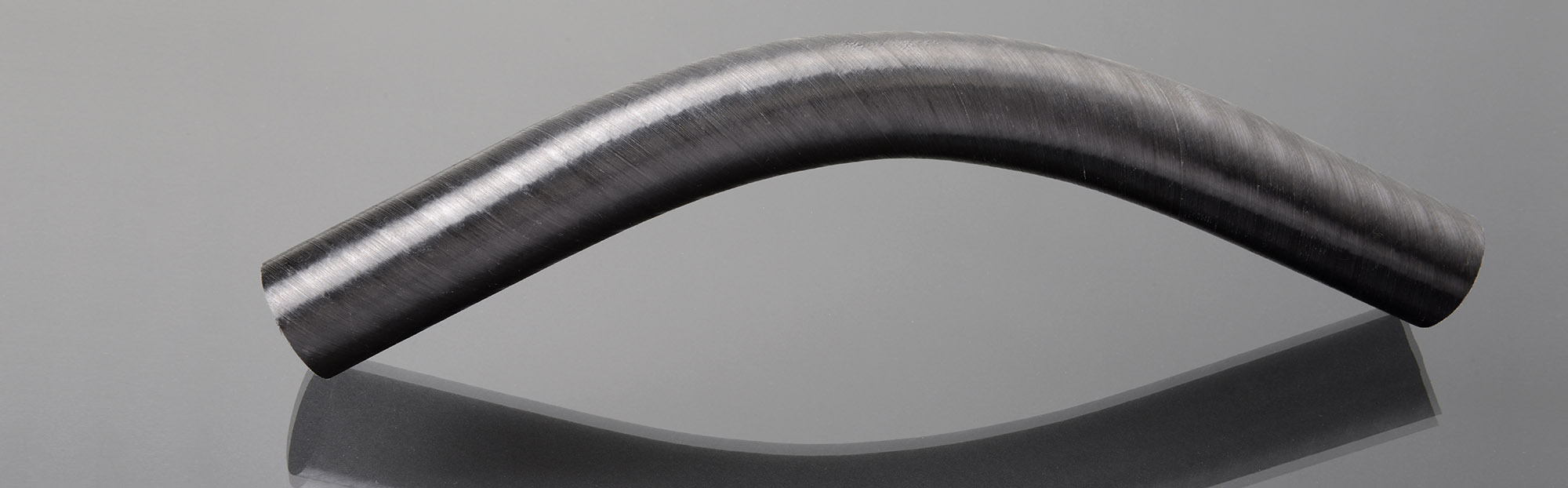

The Fraunhofer IPT has developed systems capable of the automated manufacturing of rotationally symmetrical components. The layers of thermoplastic FRP tape are fully consolidated during winding, eliminating any need for subsequent curing and autoclave processes. Whether oil and gas pipelines or pressure vessels for the automotive industry, the production process, is capable of manufacturing continuous or discontinuous components for a wide range of sectors, such as gas and hydrogen storage systems for automotive industry. Additionally, other non-symmetrical products for any specified structure can be designed entirely as required by the individual application and load.

Process optimization and prototype production

We design the process and system technology to be application-specific, focusing on increased process speed and enhanced production quality. We use the flexible tape-winding systems developed in-house to validate the optimized processes via the production of prototypes. The processes are documented on the basis of data such as process temperature, compression force or feed speed which are recorded online. A digital shadow of the part is generated by linking the data with the position of the measuring point. Direct correlation between faults in the part and irregularities in the production process further expand and deepen our understanding of the process enabling us to target process optimization activities.

Our services

- Conducting market studies and consultancy relating to application of FRP tape-winding processes

- Providing proof of concept and profitability calculations for FRP pressure vessels and pipes

- Process development for the series production of continuously and discontinuously manufactured components

- Documented prototype production and product studies for load tests

- Developing and setting up tape winding systems adapted to customer requirements for continuous and discontinuous component production