Resilient production, reliable supply chains and local value creation are increasingly coming into focus. This poses a particular challenge for the production of plant products. The conventional cultivation of plants and food in the field is subject to locally varying location factors. These problems are further exacerbated by the ever-increasing effects of climate change, in extreme cases drought, hot spells or heavy rainfall. Therefore, in many parts of the world, plant cultivation under controlled, artificially climatized conditions can be a way out of the foreseeable consequences of climate change, which are already becoming apparent. In order to increase efficiency and reduce the amount of land required - this is particularly crucial for urban farming concepts - crops are increasingly being grown in vertical farming facilities. Vertical farming refers to the mass production of plants in a confined space in multi-storey systems and is suitable for various purposes.

Production-optimised vertical farming

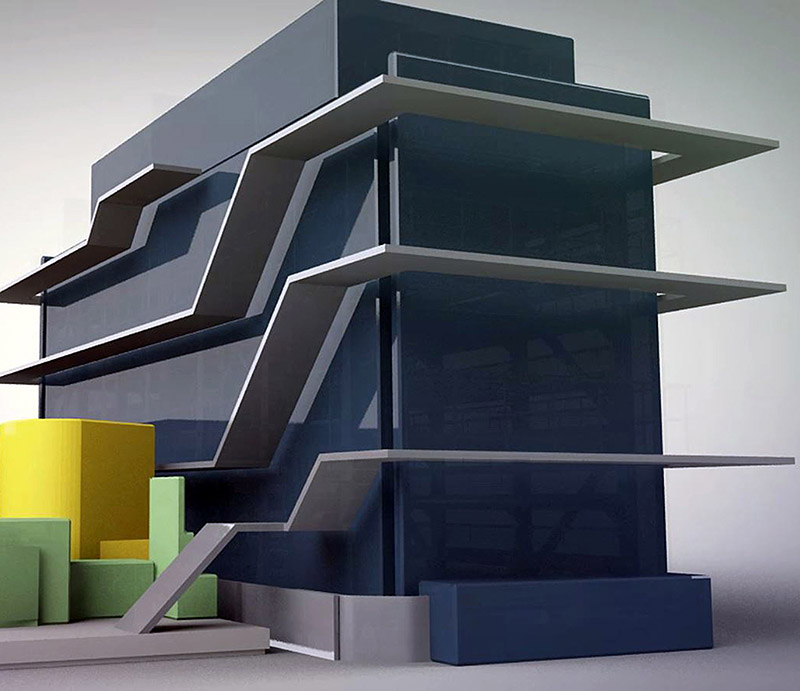

Fraunhofer IPT optimizes vertical farming systems for the respective application purposes and translates the biological requirements into engineering parameters. These design and planning parameters provide the basis for the concept of a vertical farming system for the respective application areas. The conceptual design also includes the definition of the technical building equipment as well as the superordinate production concept. We attach particular importance to the resource and energy optimisation of the vertical farming plant production system. In the overall system, all process steps are fully automated and digitized - from sowing to harvesting.

Unser Angebot

- Application-related concepts for vertical farming production systems

- Preparation of all necessary planning documents, including the technical building equipment

- Development of a customized automation solution

- Area- and resource-optimized plant design and process planning

- Supervision of the installation and commissioning

- Continuous optimization of ongoing operations

- Preparation of studies and concepts for Vertical Farming