Digitization and networking offer companies new ways of intervening in the production process of unprecedented breadth and scope. However, this also increases the complexity of the task profiles of employees. Important decisions have to be made quickly and reproducibly in order to produce efficiently and meet applicable quality standards. Adaptive decision support can make an important contribution to this.

Adaptive decision support

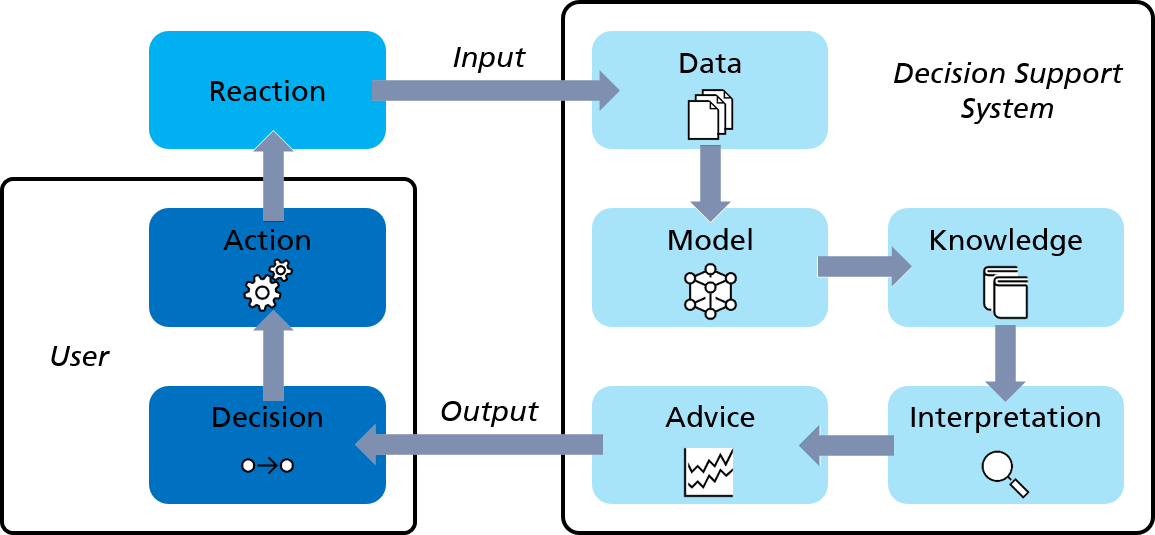

Decisions have to be made in response to different events such as sudden machine failures or new, time-critical production orders. To derive decision possibilities, the current state of production must first be analyzed. For this purpose, data from various sources, e.g. ERP, MES and CAQ systems, are combined and processed. Defined algorithms such as decision trees now automatically recommend actions to the decision maker in response to the resulting event. With artificial intelligence, decisions can be analyzed and further taken into account to derive future recommendations for action.

Our range of services

- Identification and formalization of relevant events

- Identification and analysis of influencing factors in decision-making and comparison with the previous state of digitization (data availability and quality, standardization and frequency of data recording)

- Concepts for automatic adaptive decision support

- Prototype implementation and validation