The Fraunhofer IPT is developing manufacturing processes and large-scale production chains for different components of a fuel cell stack. The aim is to reduce the high manufacturing costs of stack components. By further developing and automating the production steps, it should be possible to meet the growing demand for fuel cells and electrolyzers and to make large-scale production of stacks more efficient.

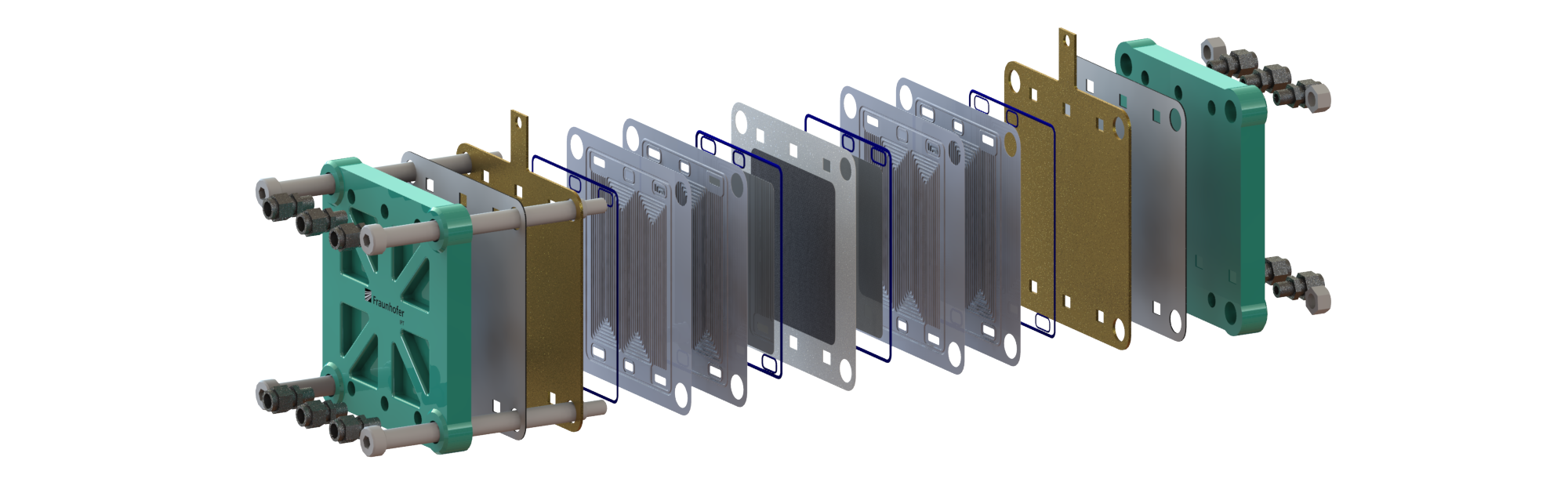

Here, the Fraunhofer IPT focuses on the core components of a stack: the bipolar plate (BPP) and membrane electrode assembly (MEA) as well as the assembly of the entire stack. Together, these components form one of many individual cells that are connected in series in hundreds. In the case of electrolyser stacks, an electrical input power of several megawatts can be used in this way for the production of green hydrogen. The electrical output power of such fuel cell stacks can be more than 100 kilowatts.

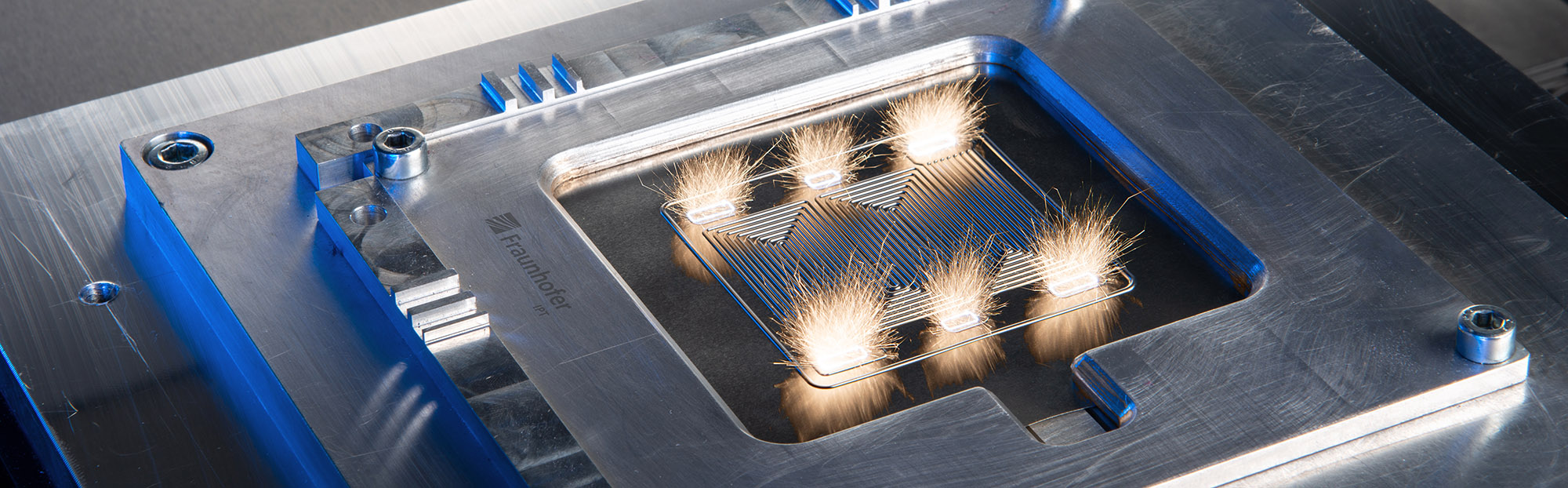

Bipolar plates go through several individual steps in production. The Fraunhofer IPT analyzes and optimizes key production steps in preparation for large-scale production. These include forming as well as laser cutting and laser welding. Different processes are tested and evaluated experimentally for the application of the seal.

The production of MEA consists of continuous processes for coating and discrete manufacturing of individual components continuous and discontinuous processes used.

In addition to high positioning accuracy of the individual components, the selection of production technologies is crucial for resource-saving insertion of the catalyst. In order to assemble the individual components into a stack in a fully automated manner within a short period of time, we analyze various technologies and select suitable processes for handling the components.