Laser structuring with an industrial robot: Functionalizing large areas faster and more cost-effectively

Laser structuring is one of the most precise and environmentally friendly technologies for functionalizing surfaces – but structuring large surfaces is still too expensive for many companies. The Fraunhofer Institute for Production Technology IPT has now created the conditions for structuring large, shiny surfaces of metallic components with high precision using a conventional industrial robot. The Aachen researchers have reduced the enormous amounts of data generated in conventional path planning by using so called procedural structures. The new methods are being verified using a five-meter-long structured turbine rotor blade.

Microstructures and nanostructures change the optical, mechanical, haptic and biological properties of surfaces. When provided with microstructures, plastic surfaces in automobiles, for example, have a better grip and higher quality. In engine components, the right surface treatment reduces air resistance. A fairly new and promising process for introducing structures into freely formed surfaces is laser structuring. In this process, a focused, pulsed laser beam is passed quickly and with high precision over the component surface. Compared to conventional processes such as coating or etching, laser structuring is more environmentally friendly, more precise and offers more design freedom.

Existing laser systems work with high precision and deliver excellent results, However, they are very limited in processing large components due to the rather small working area of those machines. In order to provide large surfaces with functional structures, large, expensive machine systems are required – in other words, high investments that not every company can or wants to make.

Structuring large surfaces with conventional industrial robots

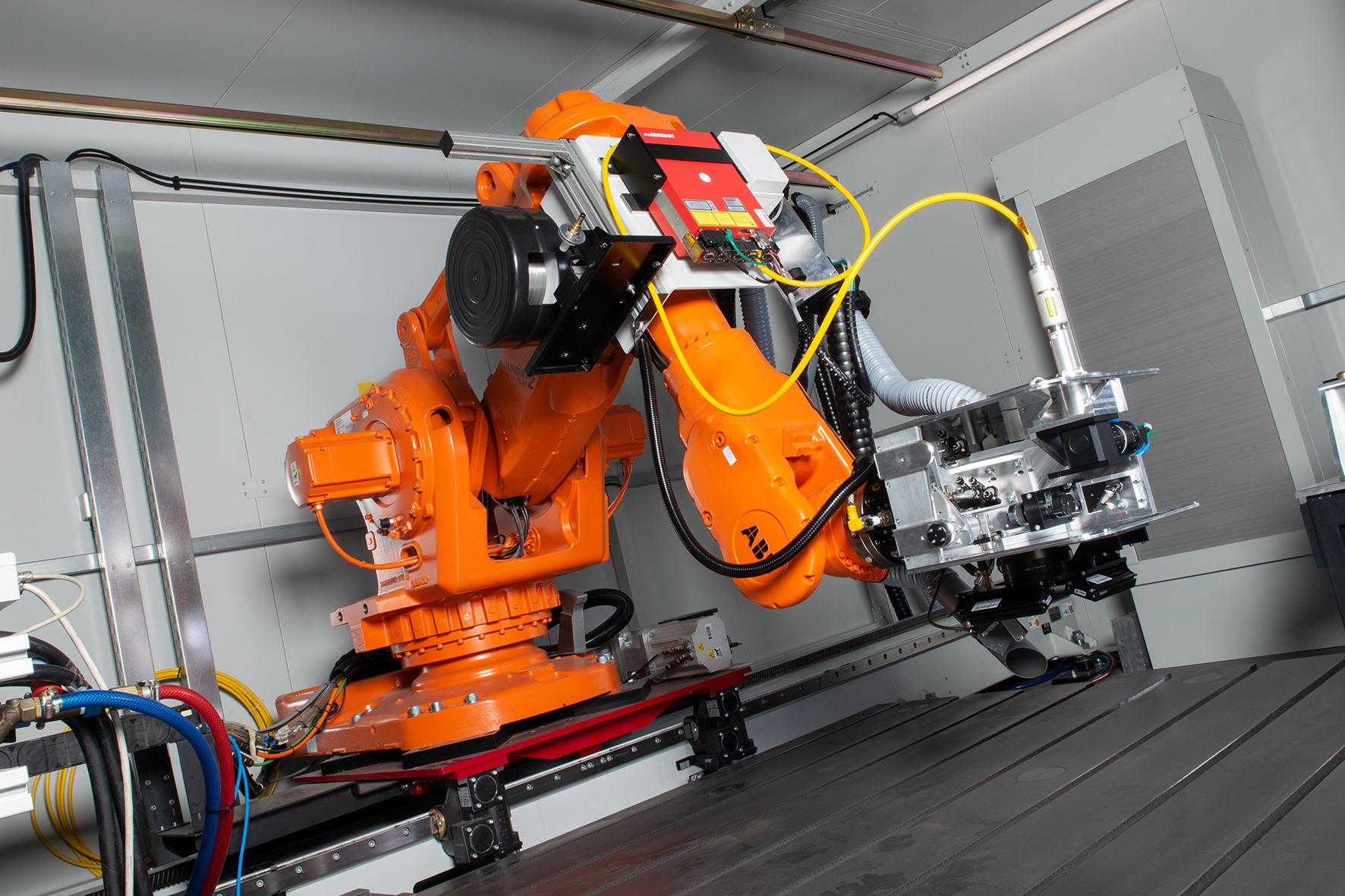

In the "GroRoLas3D" research project, Fraunhofer IPT has developed a method for structuring large three-dimensional surfaces of metallic components with a laser using a conventional industrial robot. The new method can be used to significantly reduce the costs of large structured components.

To compete with existing high-precision laser systems, the research team had to optimize the positional accuracy of the robot and overcome other challenges in processing metallic glossy surfaces with lasers: The result is modeling software that predicts surface reflections for different materials and positions of the processing head and can be integrated into an existing CAM system for path planning. The researchers also improved the system technology: They designed an intelligent laser structuring head that automatically detects and independently corrects position deviations.

Initial test series confirmed that the new system delivers precise results not only on matte, painted surfaces, but also on reflective, flat and curved surfaces.

Procedural structures reduce data volume and speed up the structuring process

One challenge in generating large-area micro- and nanostructures in the CAM system is that this generates huge amounts of data. In order to use conventional path planning algorithms for laser structuring, the IPT researchers had to create an extremely fine, detailed digital grid that contains all the structural information. Large components generate data volumes that cannot be processed with today's computing systems in an industrial environment.

As part of a research project at the Digital Photonic Production (DPP) research campus in Aachen, researchers at Fraunhofer IPT are translating the description models into so-called procedural structures for laser beam structuring. In this process, the micro- and nanostructures are described by mathematical functions and algorithms. The new method is much faster than the conventional, image-based method. It allows the data to be calculated in near real time and permits resolution-independent, distortion-free structuring.

Large-scale functionalization of five-meter rotor blade planned

In the coming months, the elements developed so far will be verified using a large demonstrator component: With the aid of the procedural structures, a five-meter-long turbine rotor blade in the Fraunhofer IPT's robot cell will be provided with technical structures over a large area that will significantly reduce flow resistance.

Further information on the "GroRoLas3D" research project:

www.ipt.fraunhofer.de/de/projekte/grorolas3d.html

More information on current projects in the Digital Photonic Production (DPP) research campus:

www.ipt.fraunhofer.de/de/projekte/dpp-open.html