Material efficiency of 100 percent in the manufacture and repair of components

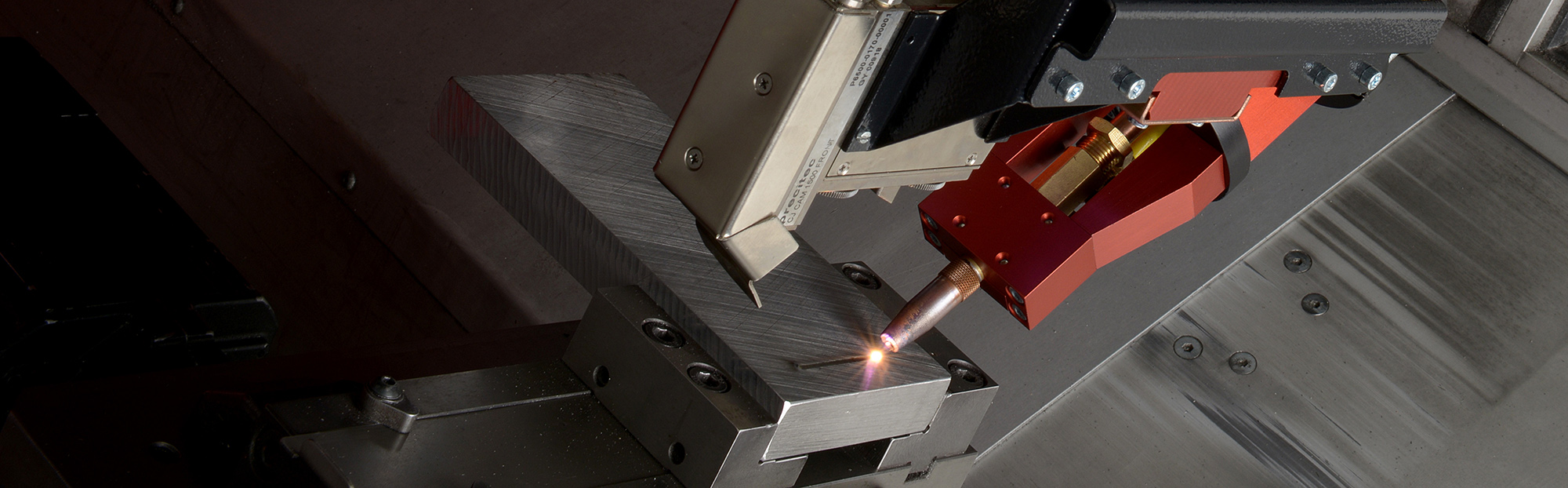

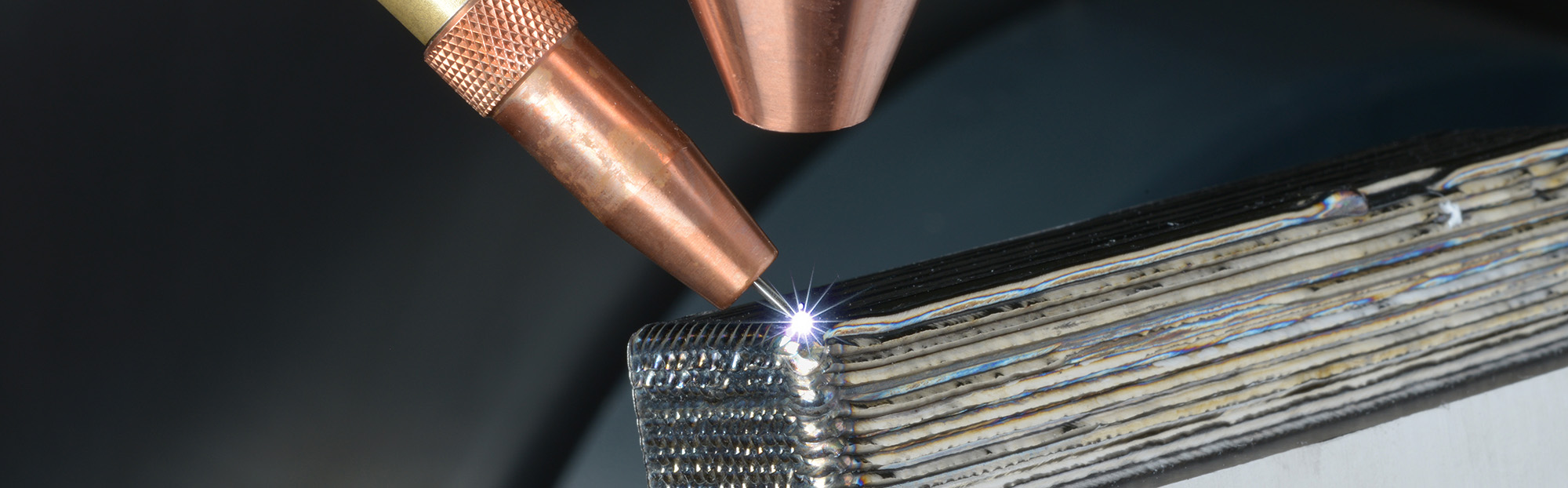

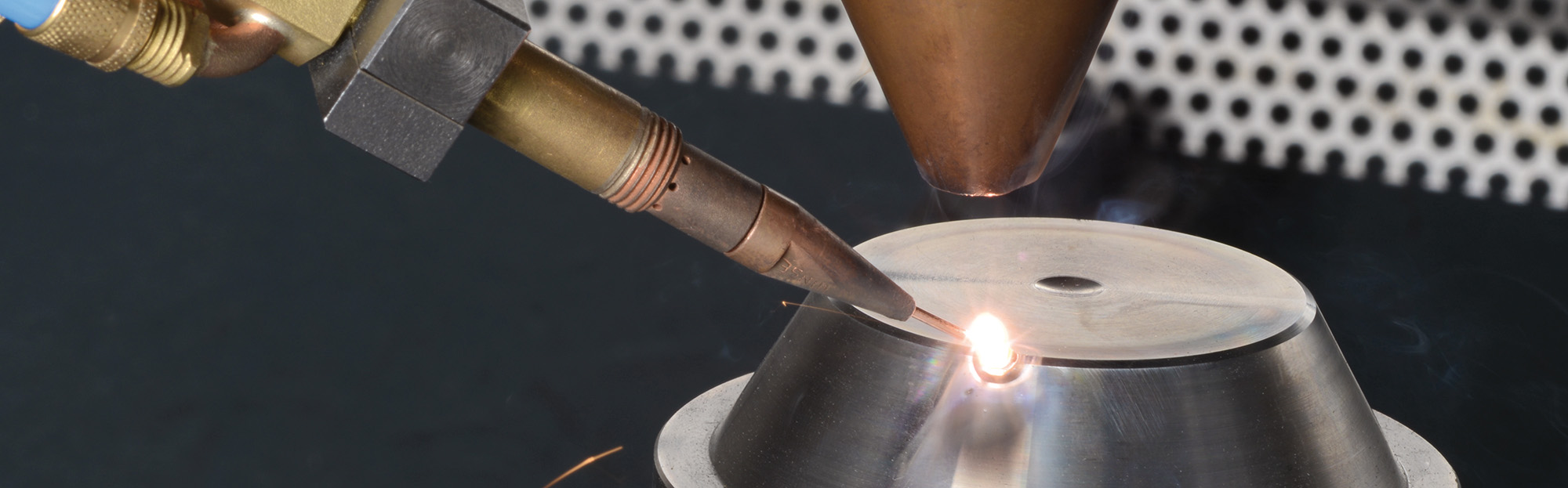

In wire-based laser metal deposition (LMD-w), a wire is melted locally with the laser beam and applied to the component surface in specific layers. In this way, the desired components or structures can be built up layer by layer. LMD-w was originally designed for wear protection. However, it is now increasingly being used as a process for additive manufacturing.

As an environmentally friendly and material-efficient alternative to powder bed-based processes, we are further developing LMD-w for the additive manufacturing of metallic components. We use our specially developed CAD/CAM software to control and regulate the production process. When using the wire additive, we have a wide range of different standardized cored wires, solid wires and special laser wires that can be processed cost-effectively and produce high-quality components.

Research and development along the entire LMD-w process chain

In our research work, we address technological and organizational challenges along the entire process chain: from optimal wire feeding to process control for different material combinations and various industrial applications.

We prepare feasibility studies for LMD-w and offer prototype manufacturing and small series testing on behalf of customers. We implement LMD-w into existing process chains and integrate laser and wire feeding systems into machine tools.

Our services at a glance

- Feasibility studies for LMD-w

- Process development and manufacturing

- Additive manufacturing of small series

- Implementation of LMD-w in existing process chains

- Construction of systems for LMD-w

- Integration of laser and wire feed systems into machine tools