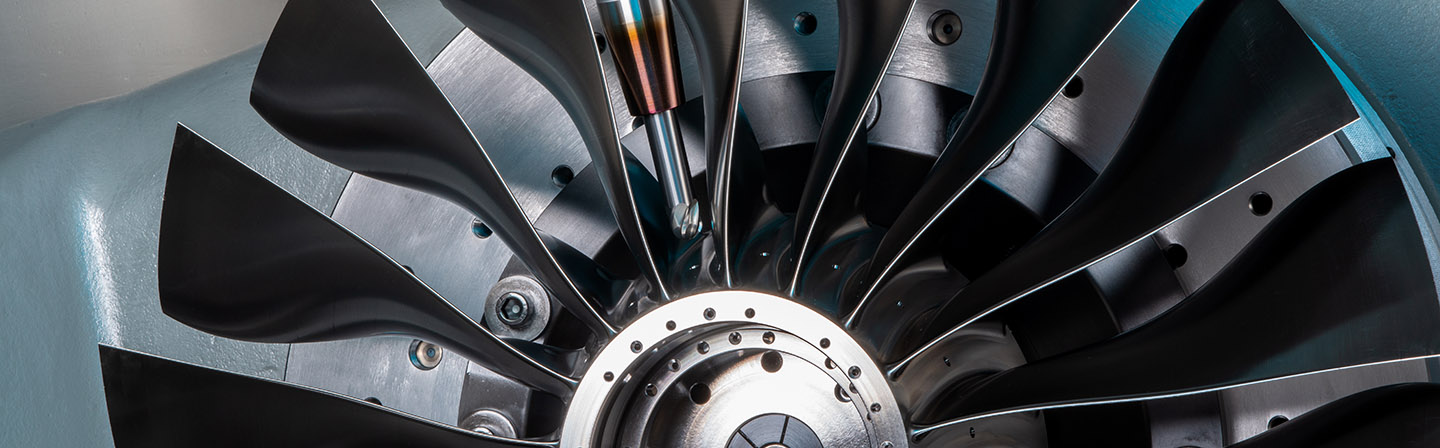

Before newly designed engine components go into series production, their efficiency and performance must be tested on the test bench. The highest quality standards must be met not only for rig use, but also later, when it comes to actual series production. To ensure that the component geometry and surface finish meet the extremely high requirements, the appropriate manufacturing processes must be selected from the outset. Precise documentation specifications for the entire production process chain are also required.

Prototype manufacturing: The entire production chain from a single source

Fraunhofer IPT has many years of expertise in the production of rotating engine components in integral and differential design. We always consider not only the individual process step, but the entire production chain: from production planning and machining to newer processes such as electrical discharge machining (EDM) and electrochemical machining (ECM). In addition to our specialty – the production of fluidic components – our research and development work also includes the manufacture of housing components and the machining of shafts.

We supplement our portfolio with special processes such as fluorescent penetrant inspection (FPI), shot peening, balancing, visual inspection and segregation etching. We ensure component quality using both optical and tactile measuring methods.

Digital production ensures the highest quality

We manufacture prototypes of engine components of the highest quality for our customers and project partners and continuously improve the manufacturing processes based on the production data obtained. To ensure efficient and rapid component production, we first simulate the process design and use our fully digitalized start-up environment. The manufactured components are suitable for immediate use as a "turnkey solution" for further testing in our customers' test environment. All manufacturing processes are subject to comprehensive quality assurance and documentation.