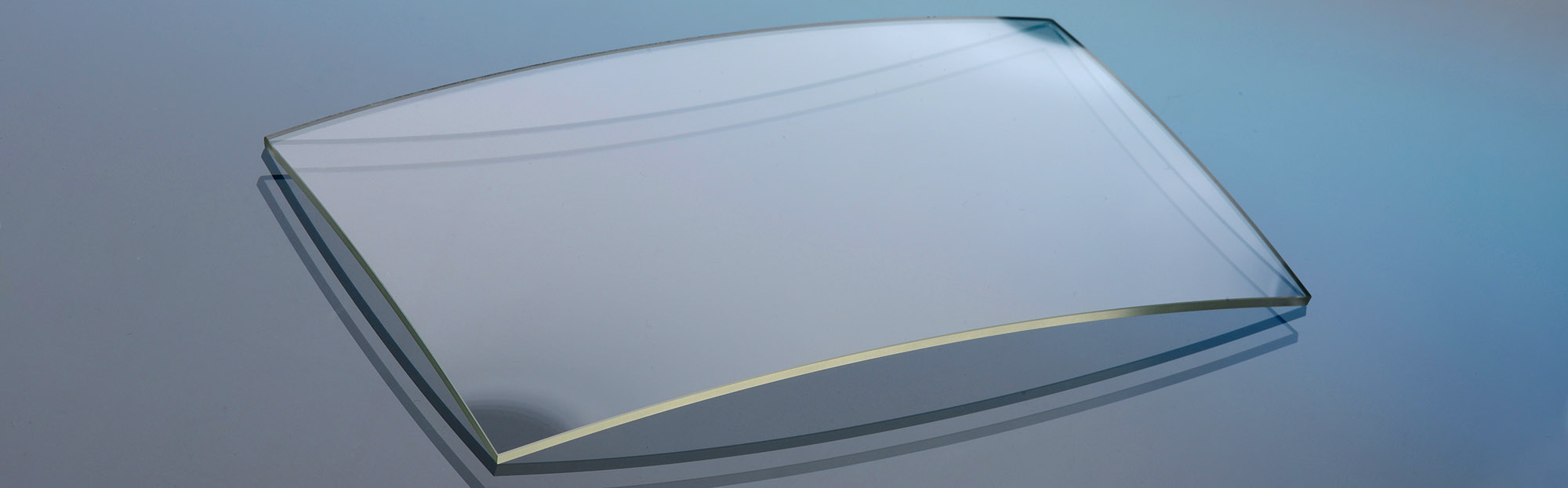

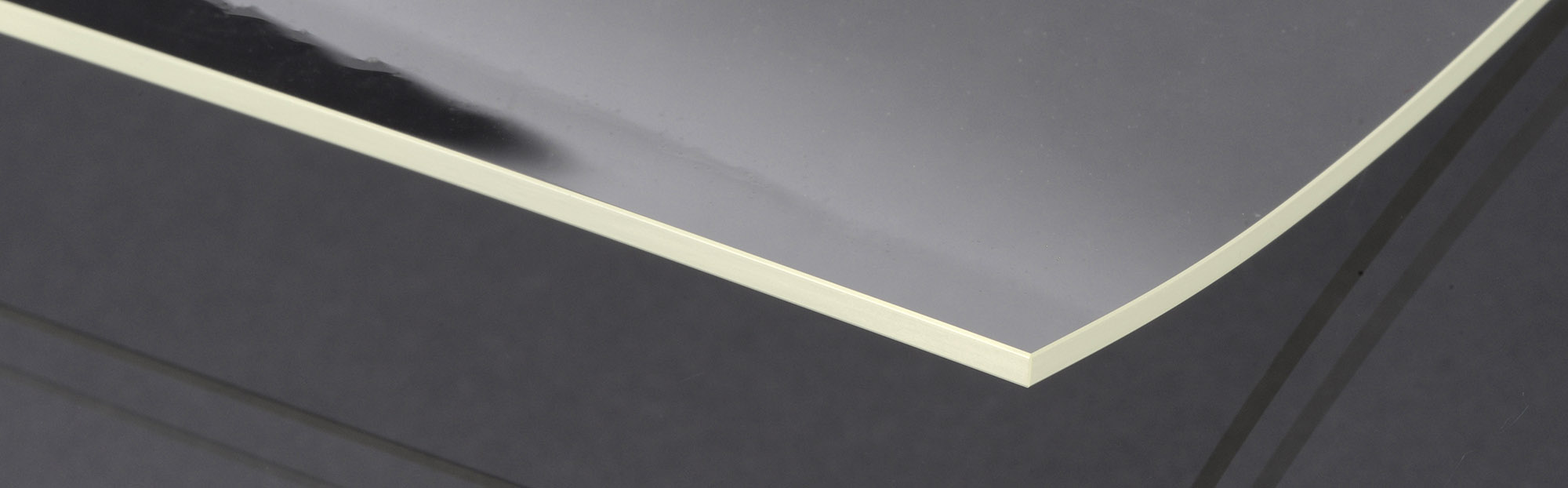

In gravity lowering, a thin glass is heated and formed under its own weight. Vacuum-assisted process control enables us to achieve high forming rates even with small surfaces, especially for thin glass with a thickness of less than one millimeter. Furthermore, the use of vacuum can significantly reduce the forming temperature, which has a positive effect on the service life of the forming tools. In addition, the tool occupancy time can be greatly reduced. For gravity lowering and vacuum assisted lowering, we develop automation solutions and manufacturing concepts for mass production.

Our services

- Process knowledge and process execution along the entire production chain

- Market studies on the recycling of thin glass products

- Design and layout of the moulds

- Production of forming tools

- Simulation

- Implementation of systematic test series

- Data management: Solutions for recording data along the entire process chain

- Development of strategies for economic qualification

- Development of optimal measuring processes

- Analysis of the value stream