Digitization and networking are increasingly finding their way into production. The consistent use of data opens up far-reaching potential for production optimization. Traditional approaches, for example to identify fluctuating quality parameters, are reaching their limits due to the increasing individualization of products.

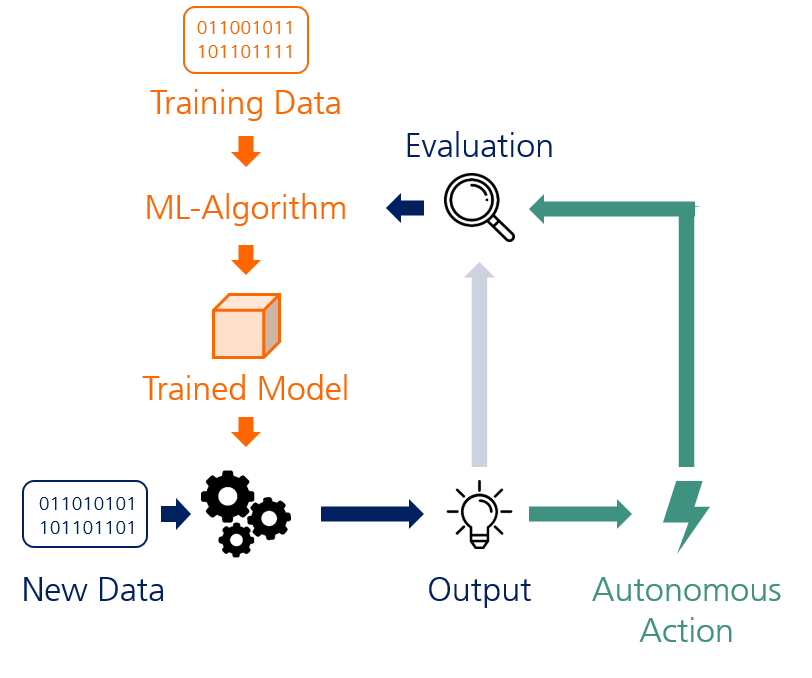

A systematic and cross-process analysis of data using new technologies such as machine learning and artificial intelligence makes it possible to further improve both processes and products. In this way, process and product data can be used specifically for predictive maintenance, process optimization or predictive quality. Thus data contributes to avoiding machine downtimes, shortening throughput times and improving the quality of processes and products.

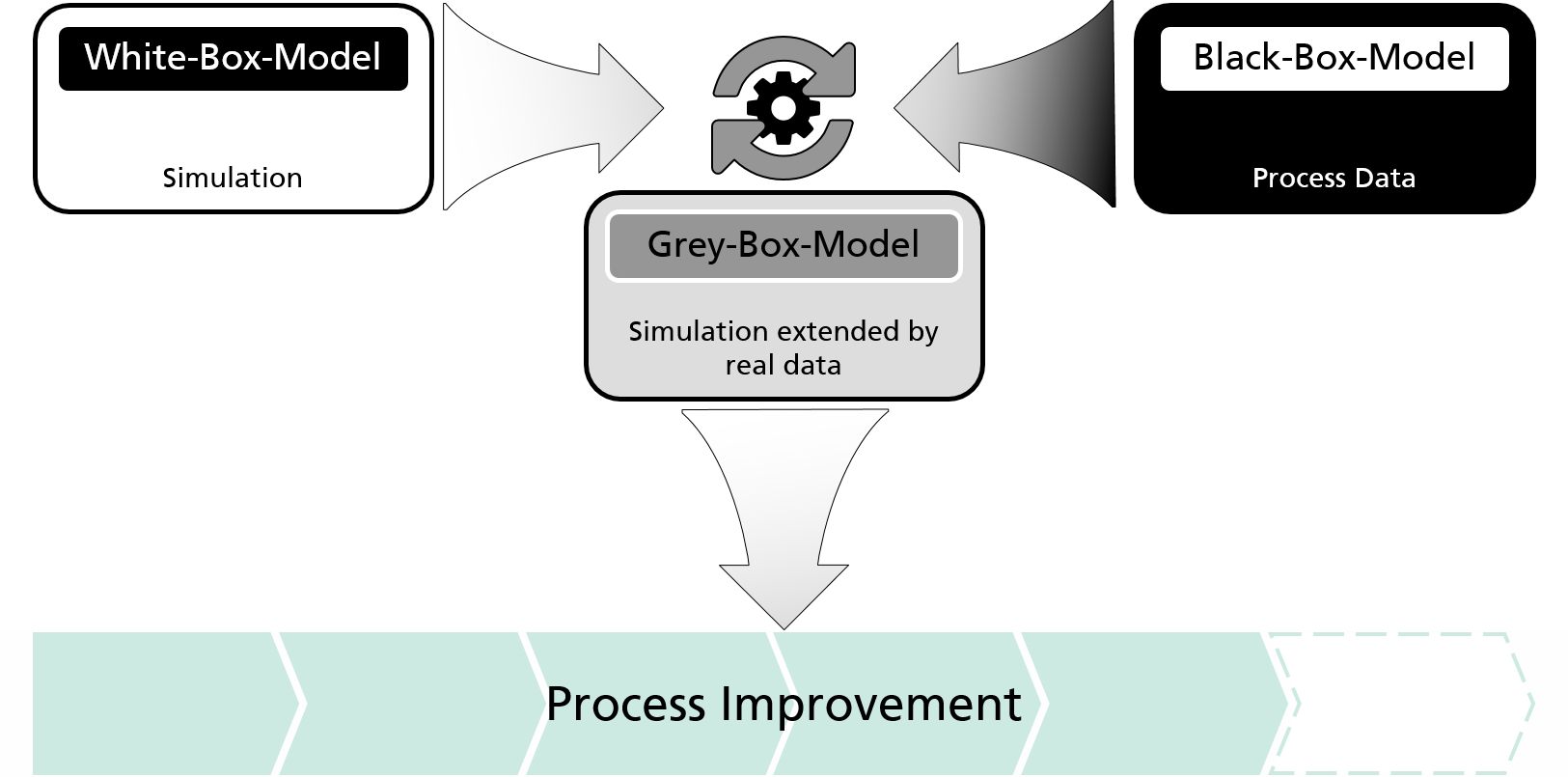

Hybrid modelling

In order to further improve data-driven modeling, the Fraunhofer IPT is researching various modeling strategies and their possible combinations (grey-box modeling). The aim is to combine the advantages of different modeling strategies by skillful combination. For example, the Fraunhofer IPT is investigating approaches for combining physical simulation (white-box modeling) and data-driven approaches (black-box modeling) with a view to their potential for application in production.

Automation of the modelling process

New approaches to machine learning such as AutoML help to automate the creation of machine learning models to a large extent. The aim is to improve the accessibility of machine learning by increasing its ease of use without special training. This is for example achieved through automated data preparation or the targeted selection of algorithms and hyper-parameters.

However, modelling is not enough to fully exploit the potential of data-driven approaches. Practice-oriented optimization strategies support the acquisition of new knowledge by combining modelling and the use of existing knowledge about processes and products in the company.

Our range of services

- Industrie 4.0 audit

- Data-driven modelling of production processes

- Project work for data-driven optimization

- Identification of promising applications in industry