Harnessing the earth's heat to generate renewable energy is worthwhile. Geothermal wells in deeper layers of the earth's crust are particularly profitable. However, with in-creasing depth, the costs of drilling rise disproportionately due to wear of the drilling tools and low rates of penetration - and thus also the financial risk. The Fraunhofer IPT is using a combination of water and a high-power laser to develop a drilling method that can significantly reduce the costs of deep geothermal drilling and thus produce a more cost efficient supply of geothermal energy in Germany.

With the high-power laser through hard rock

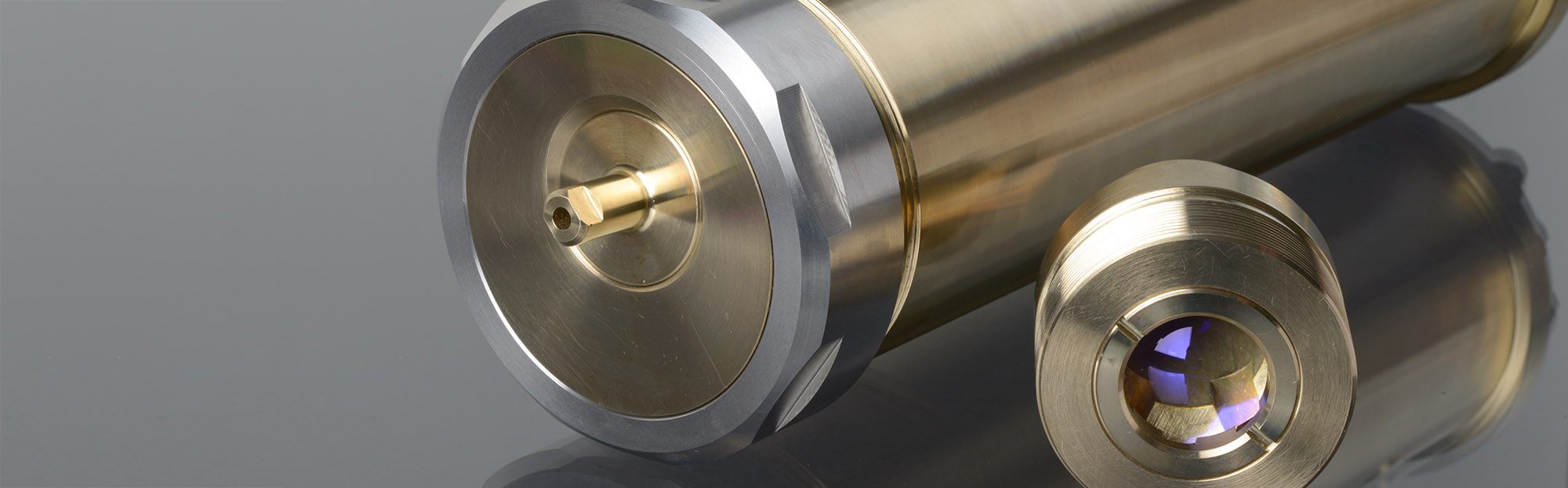

In addition to a conventional mechanical drill head, a water-guided high-power laser beam is used. In order to drill hard rock such as granite at a reasonable cost, a laser power of up to 30 kW is required, which is introduced into the borehole in a precise manner by the laser-water-jet and therefore supports the mechanical drilling process. In laboratory tests, the Aachen and Bochum engineers were able to demonstrate a weak-ening of quartzite and granite with an initial strength of more than 150 MPa by 40 to 80 percent. In this way, the wear of the drilling tool is reduced to a minimum - with faster ROP at the same time. The water jet not only guides the laser beam right down to the hard rock, but also prevents contamination and damage to the sensitive laser optics.

The system was developed in the "LaserJetDrilling" project and is similar to the technol-ogy that was previously only used in micromachining. The project partners now trans-ferred this technological approach to geothermal drilling on a large scale and validated the technology in mid-2018 at the Geothermal Center Bochum by conducting near-surface drilling tests in hard rock. In order to couple the laser radiation into the rotating drill string, the Fraunhofer IPT developed a special fiber optic rotary joint that allows the high laser power to be transmitted from the laser source to the drill head with virtually no losses.