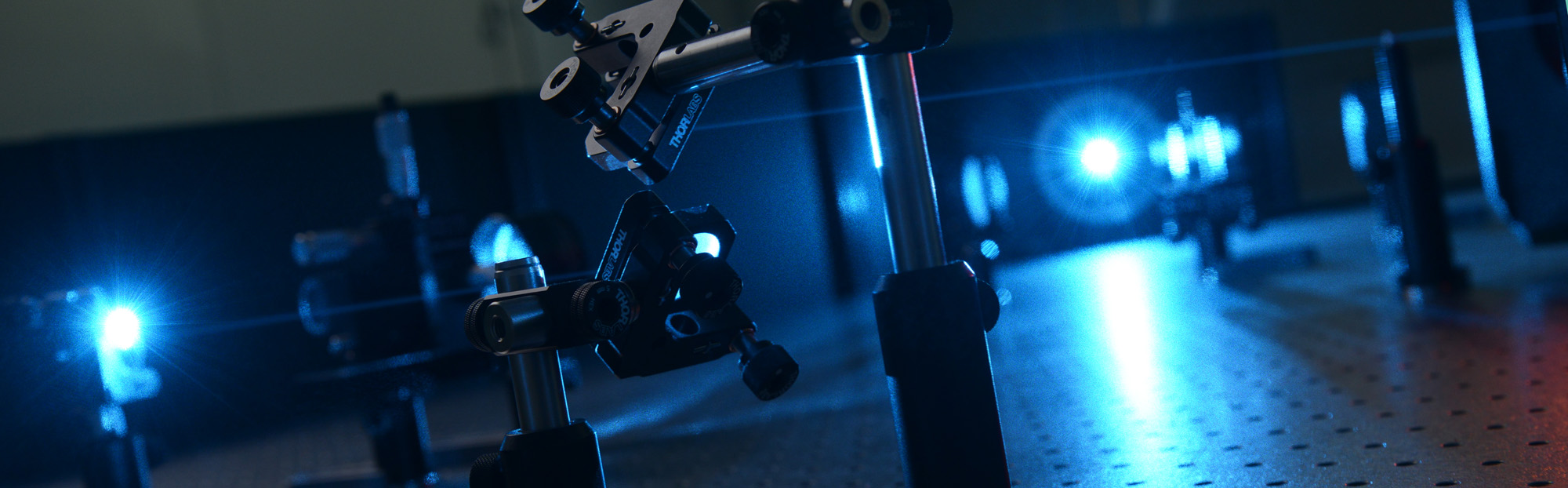

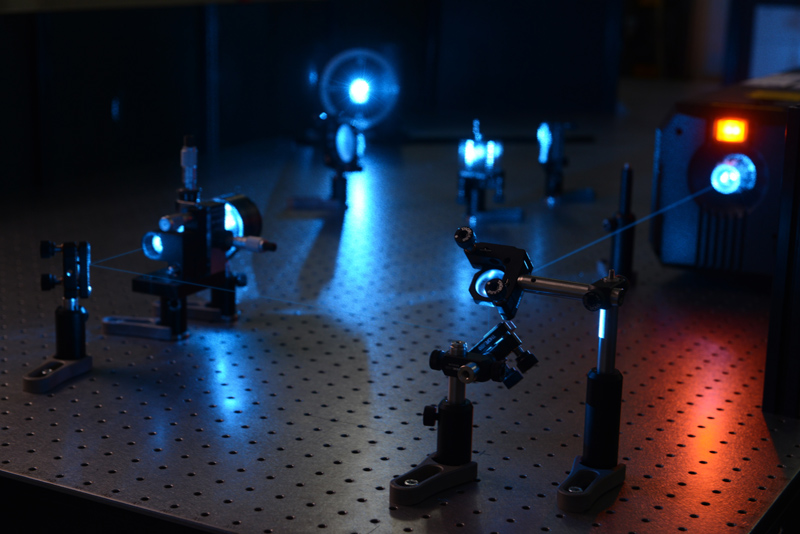

In interference lithography, the beam of an argon laser is widened, divided and brought to interference by superposition. By positioning a photosensitive sample in this interference pattern, the pattern is stored as a linear structure in the polymer. The superposition angle of the two partial beams and the wavelength used determine the lattice constant of the structure. Multiple exposure after rotation of the sample allows cross- or hexagonal structures in addition to line gratings.

The Fraunhofer IPT uses a Spatial Light Modulator (SLM) to individualize the wave front of a partial beam and thus the structural geometry. The structures serve as masters for a galvanic impression in nickel, which is finally used as a tool in precision moulding.

The aim of the Fraunhofer IPT is to use SLM to create more individual structures and structures on curved surfaces in order to optimize the energy efficiency of the corresponding optical systems.

Our service

- Feasibility studies for periodic structures, also on curved surfaces

- Parameter tests to optimize individual structures

- Impression of the structures in silicone or nickel