Grinding high-precision parts made of hard and brittle materials

High-precision parts made of hard and brittle materials such as tungsten carbide, ceramics or glass, are used in a range of sectors including tool and die making industry, the optical industry or in medical technology applications. The outstanding features of these materials are their extremely high resistance to wear and temperature, high hardness and low fracture toughness. As a result of these characteristics, the materials can be machined only via cutting operations in which a geometrically undefined cutting edges are used. Grinding is one such operation. Accordingly, wherever a part with high-precision surfaces is to be produced, an ultra-precision grinding process is essential.

We draw on long year experience in grinding technology, particularly in ultra-precision grinding not only to further our scientific projects but also on behalf of our partners in the manufacturing sector. Our expertise extends way beyond grinding: We maintain very close links and work intensively with staff from other specialist fields within Fraunhofer IPT, including experts from the Process Technology, Industrial Metrology and CAx Technology departments.

Our offer: Know-how and state-of-the-art machinery

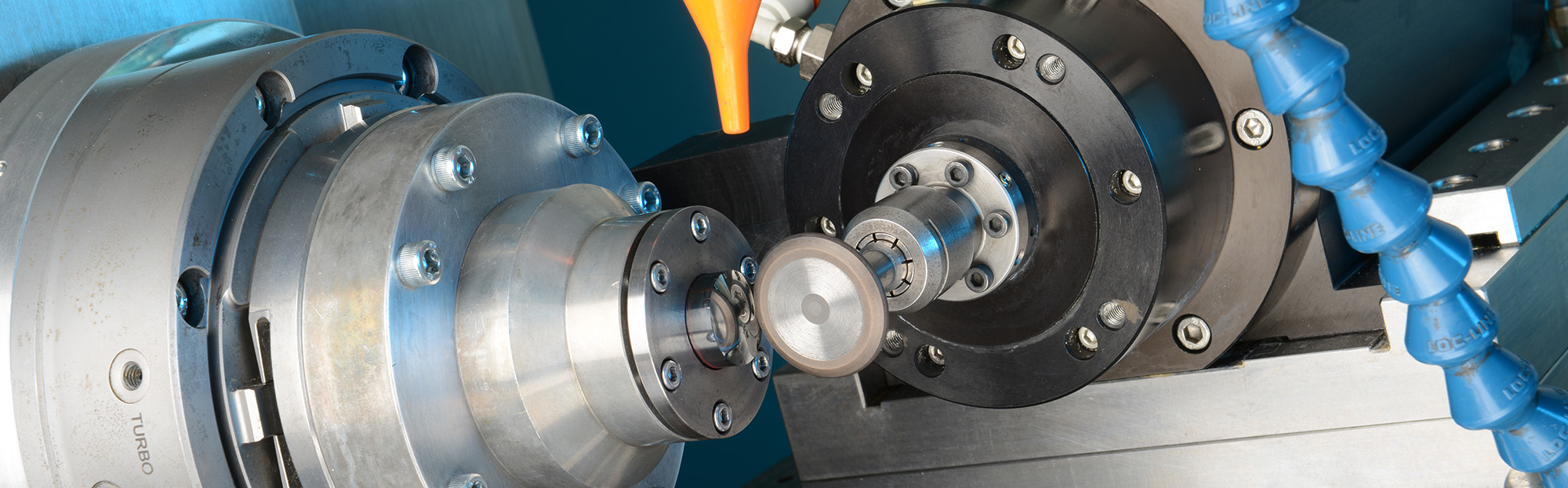

We deploy modern grinding machines with up to five axes for high-precision machining operations conducted on parts made of hard and brittle materials. We apply all of our know-how to ensure that we can meet the most exacting requirements in terms of contour accuracy and surface quality using these machines. As the machines have positioning accuracies well below one micrometer, even complex geometries can be machined in ultra-precision operations. Grinding and workpiece spindles with air bearings guarantee maximum form and surface qualities. Up-to-date measurement technologies ensure high quality of both the processes and the parts which are manufactured.

Our services

- Coordinating and executing publicly-funded research and development projects

- Conducting feasibility studies in the production of high-precision parts made from hard and brittle materials

- Optimizing existing grinding processes

- Qualifying and establishing new processes