To manufacture structural components, industry needs to machine and process sheet metal made of steel, titanium or aluminum used in transfer or progressive dies in thicknesses in the millimeter range. In contrast, material thicknesses of below 0.5 mm are used in thin sheet metal processing.

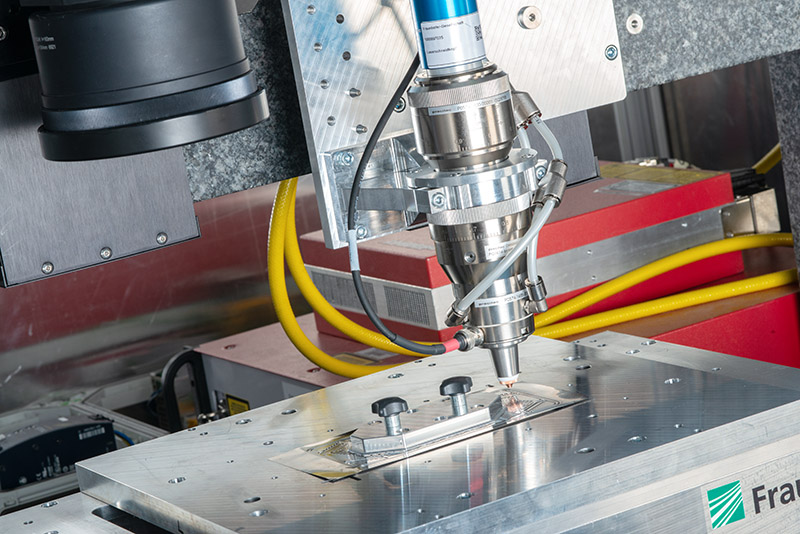

At Fraunhofer IPT, we process thin sheets as part of our hydrogen projects. Our research and development work focuses on the production of bipolar plates, a key component of fuel cells and electrolyzers.

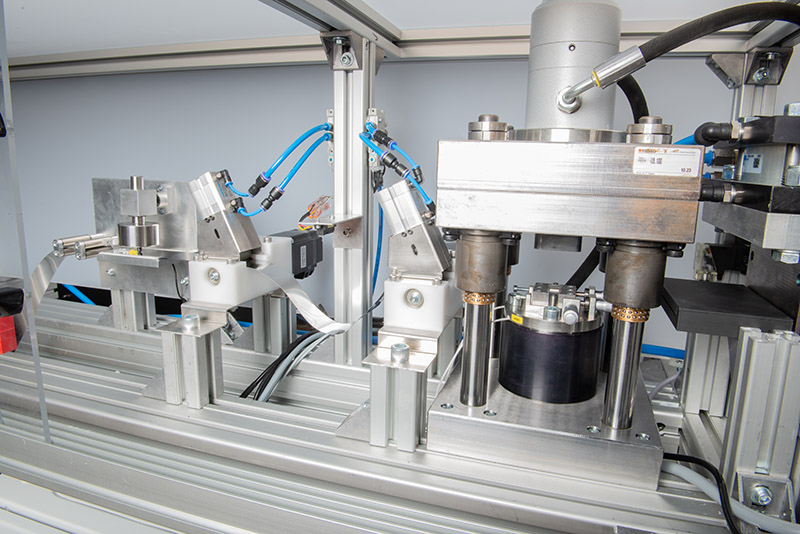

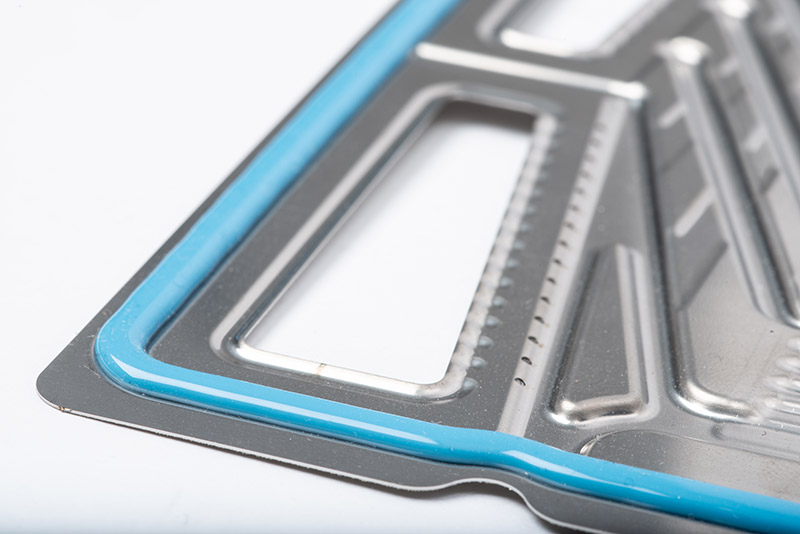

We have mastered all the key process technologies for the production of bipolar plates: from discrete or continuous forming, laser cutting and welding of the bipolar plate half-shells and their handling through to functional testing of the bipolar plate and the application of the sealing contour. In addition to bipolar plates, we also produce multilayer porous transport layers (PTLs) on our in-house expanded metal line and welding system.