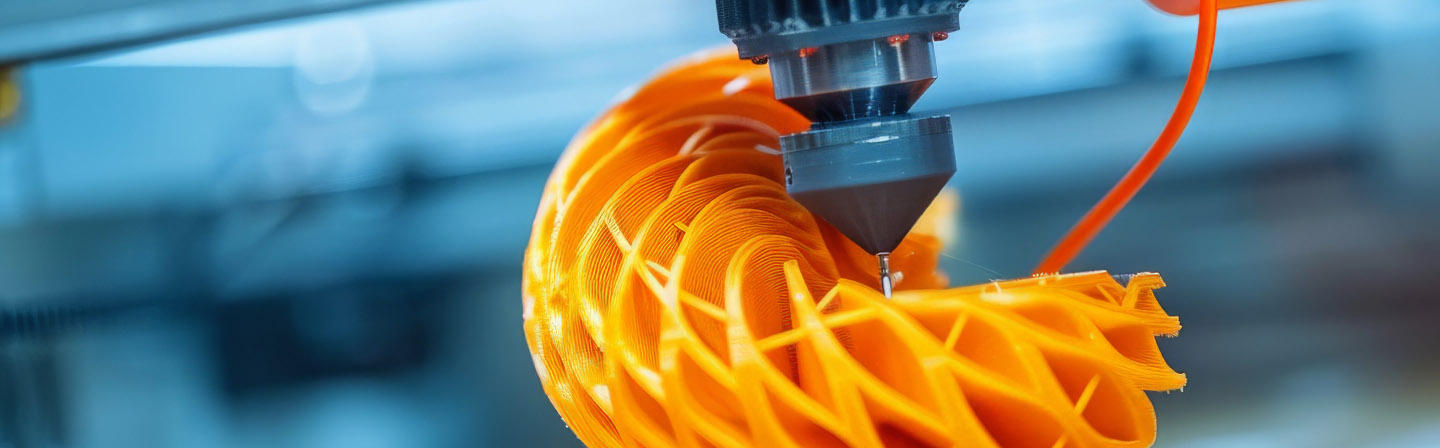

Over the past few years, the family of production technologies has welcomed a new member: additive manufacturing. The term additive manufacturing covers different processing technologies including their variations, materials with different processing properties and qualitative properties of components. None of these technologies has, however, so far been able to meet the strict standards of certain industries such as tool manufacturing, because they require component surfaces of a very high quality. The surfaces that are delivered by additive manufacturing – the technique of building up components layer-by-layer – are simply too rough.

We aim to integrate additive manufacturing techniques into existing process chains to allow companies to build on their manufacturing experiences and competencies. Such a strategy also ensures that the competitive edges that these companies have created over many years will not only be preserved but even extended by the introduction of this new and innovative technology. Our systematic approach enables you to proceed with confidence in selecting the right technologies for your components and their requirements and in determining the right spots in the process chain where to deploy them. We will enable you to base your decisions on your entire process chain structure which may also include milling processes, spark erosion and other technologies.

Our services

- Component range analysis to identify the specific requirements of the additive manufacturing facility and the process chain

- Assessment of the existing machinery in order to optimally integrate additive manufacturing technologies

- Selection of the most suitable additive technology based on a comprehensive technology survey, the analysis of existing machinery and precise specifications for the required components

- Development of a component manufacturing process chain featuring conventional, non-conventional and additive manufacturing technologies

How you can benefit

A systematic approach gives manufacturing companies the confidence to select the correct technologies for their components and to deploy these technologies at the correct points of their process chains. Decisions are based on thorough analysis of the entire process chain that may integrate a range of technologies including milling and spark erosion.

- Systematic selection of components and technologies

- Analysis and benchmarked comparisons of the existing machinery

- Integration of additive manufacturing and downstream processing activities into efficient process chains