Fiber-reinforced plastics (FRP) are ideal for lightweight construction and are being used more and more frequently in many fields of application, from mobility and transportation to construction and energy generation: wherever low component weight is important, they also score with their good corrosion resistance and electrical insulation.

For this reason, lightweight materials such as glass fiber reinforced plastics (GFRP) can be found, for example, in numerous components for wind turbine blades, sport boat hulls, antenna, lantern and overhead line masts or pipe systems. Carbon fiber reinforced plastics (CFRP) are widely used in vehicle construction, aerospace and sports equipment and other lightweight but highly durable consumer products.

Automation solutions for the cost-effective series production of FRP components

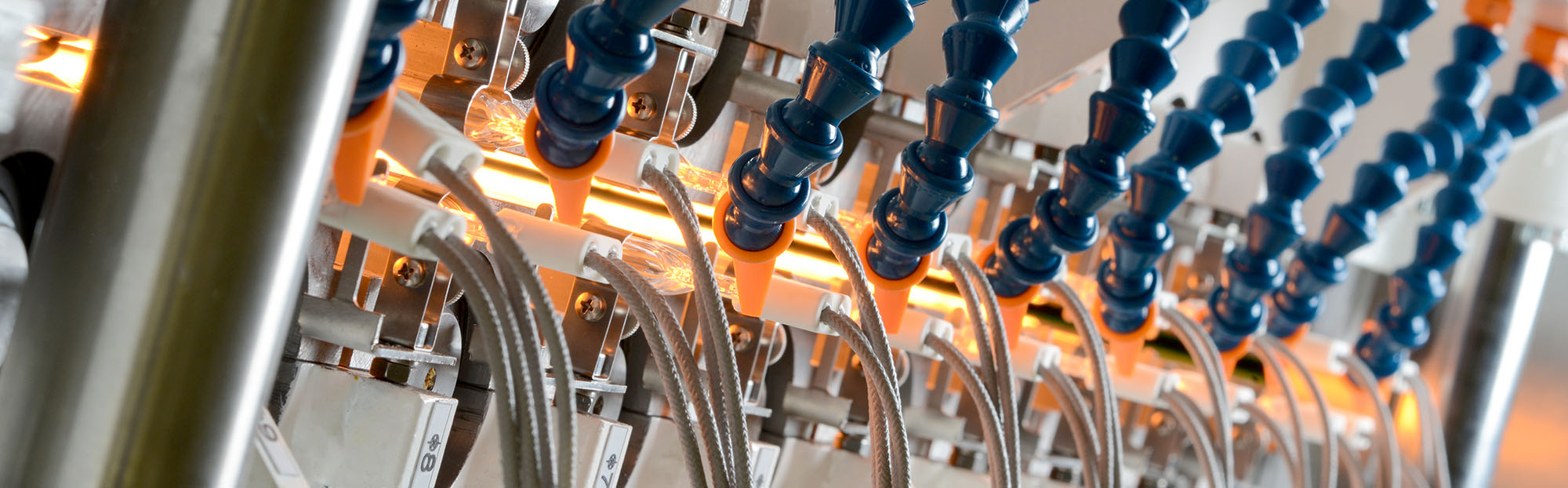

This increasing industrial use of a wide variety of FRPs is leading to growing demand for processing methods suitable for large-scale production. The use of unidirectional thermoplastic tapes and thermoset prepregs makes it possible to fully automate the manufacture of FRPs and transfer them to large-scale production. Fraunhofer IPT is developing systems and processes for automated tape and prepreg processing of such FRP materials, enabling companies to move into customized, efficient and cost-effective series production.

New approaches to data collection and utilization, as well as virtual process models, create the prerequisites for adaptable, large-series processing of glass- and carbon-fiber-reinforced thermoplastics and thermosets. Fraunhofer IPT automates the systems and processes for processing these materials, thus enabling efficient and flexible production of lightweight components for various industries.