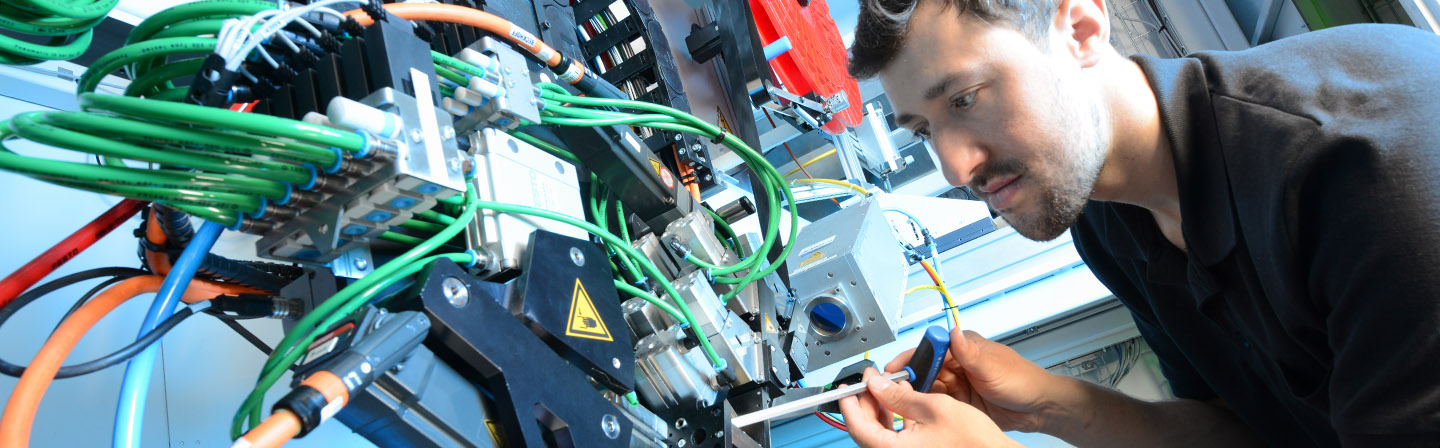

The multifunctional tape laying systems "PrePro 2D" and "PrePro 3D", which was developed at Fraunhofer IPT, can be used to process thermoplastic tapes and thermoset prepregs as well as spread and bindered dry fiber rovings. Processing these semi-finished products with just a single system reduces the amount of machinery required and increases flexibility in the production of lightweight components. Thanks to its modular design, the system can be quickly and flexibly adapted to different semi-finished products depending on requirements and individually retooled for the respective applications.