Manufacturing processes for tissue engineering

Tissue engineering is where biology meets technology: the aim is to cure diseases and support natural tissue repair following trauma using tissue cells generated in vitro. Biotechnological tissue engineering processes are currently being used to obtain replacement human tissue cells from stem cells with the aim to deploy them for use in personalized medicine.

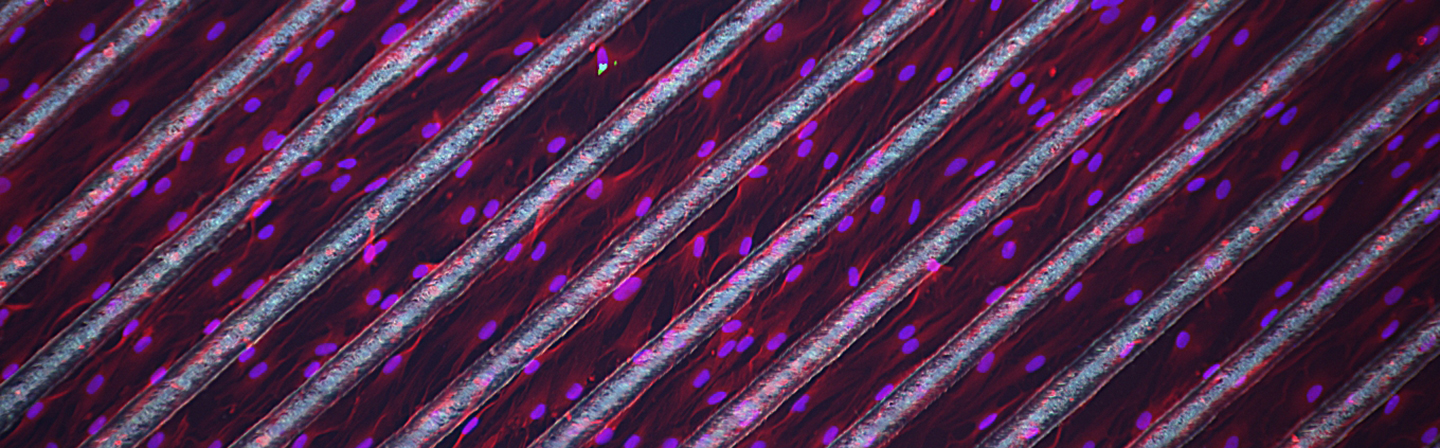

Structured biomaterials with tissue-specific stiffness

To trigger stem cells to grow and differentiate into specific tissues, it is crucial to simulate the direct, in vivo environment of these particular tissues. The Fraunhofer IPT has developed a tissue engineering process which allows biomaterials to be both nano and micro structured. Biomaterials with tissue-specific stiffness can be molded with a range of topographies at our in-house laboratory for applied cell biology. Added functionality and increased differentiation of the stem cells has been achieved through electrical and biomechanical pulses such as electromagnetic current, ultrasound, light, tensile stress or fluid flows.

Applying measuring technology to achieve controlled cell growth

By fostering interdisciplinary collaboration between biologists and engineers, we have successfully simulated biological systems such as tissue equivalent materials and stem cell niches and enabled stem cells to differentiate into specific tissue cells. In addition to this, we measure and interpolate the biological signals sent by the differentiated cells to enable us to record their particular functionalities.

From prototypes to scaling up production

We rely on diamond cutting, two-photon lithography and laser structuring to produce micro and nano structured embossing dies. The structures can be tested on the molded substrate prototypes. If cell differentiation is successful on the substrates, we can optimize the manufacturing process in the next step and carry out manufacturing processes to scale up production. In this context, we use roll-to-roll and injection molding operations.

Our services

- Developing specific stem cell niches and tissue constructs

- Mechanical stimulation via specific surface structuring, tensile stress, fluid flows and ultrasound

- Electromagnetic stimulation

- Analyzing the function of the target tissue by measuring cellular activity and external forces affecting the cell

- Characterizing differentiated cells at gene and protein level

- Up-scaling the production process to mass produce differentiated tissue cells.