Free digital platform with test offer for digital cloud services, NC data analyses and machine learning

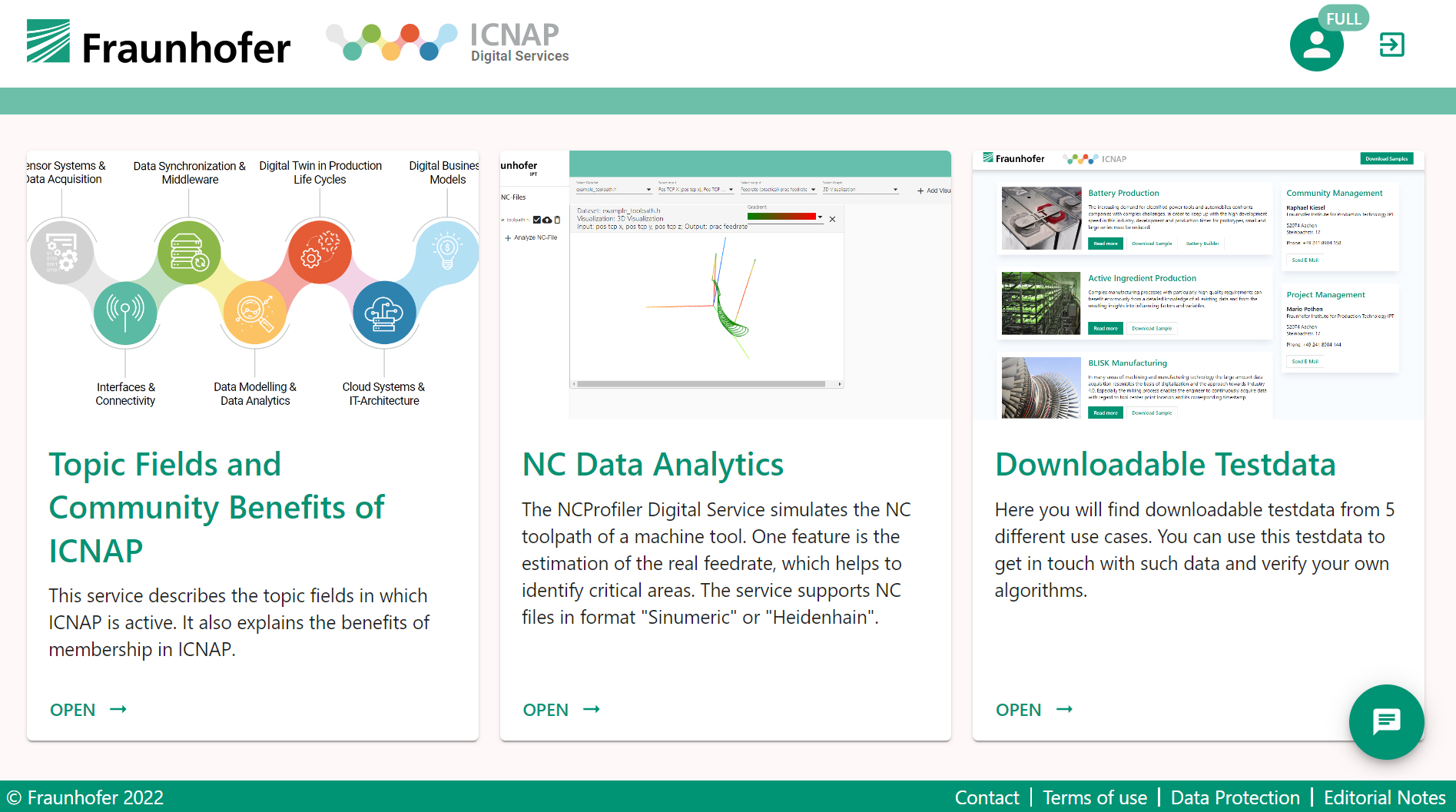

The digital networking of machines and systems offers enormous opportunities to make production chains more efficient, flexible and sustainable. However, small and medium-sized manufacturing companies are uncertain about which specific information technology solutions are suitable for their production environment and what benefits they actually provide. The "International Center for Networked, Adaptive Production ICNAP", a consortium of three Fraunhofer Institutes in Aachen, is now providing a digital service portal for interested companies, offering them the opportunity to familiarize themselves with the benefits of a digital toolbox for networked, adaptive production. As of now, services such as an NC data analysis or an assistance system for the targeted selection of machine learning algorithms can be tested free of charge.

Why should a company intervene in well-functioning production processes? To what extent can existing processes be optimized or even redesigned using digital methods? IT solutions can usually be better assessed and evaluated on the basis of actual applications than with the help of guided presentations and software or hardware demos at trade fairs or on-site at the provider's premises. To give companies a deeper insight into the digital toolbox of networked, adaptive production and to present concrete solutions, the Fraunhofer team of experts has developed the "Digital Service Portal" together with ICNAP's industry partners.

Service offerings and analysis tools for the digitalization of production

The portal makes numerous digital offers to users to familiarize themselves with Big Data analysis methods and other IT tools. For example, manufacturing companies can have individual production processes analyzed on the basis of NC data from different machines and systems. A new machine learning approach makes it easier for employees without special training to apply machine learning models by automatically processing the data and suggesting suitable algorithms by the system.

For example, a so-called battery module configurator is available for electromobility applications: The configurator suggests battery cells suitable for the respective application and recommends parameters for laser beam welding to join the individual modules.

The ICNAP Digital Service Portal is based on Fraunhofer Edge Cloud, which was developed in collaboration with the company's partner German Edge Cloud. Following registration, users can test the various service offerings. The scientific contact persons of the Aachen Fraunhofer institutes are available for more in-depth interest or questions about further, also individual applications.

Working out solutions together in the ICNAP community

The three Aachen-based Fraunhofer Institutes for Production Technology IPT, for Laser Technology ILT and for Molecular Biology and Applied Ecology IME are working together with other experts from industry and research in the ICNAP to identify the new solutions from information technology that can actually bring about the transformation to Industry 4.0 and the prerequisites that need to be met in the process. The ICNAP community currently comprises more than 20 partners who are working together to develop solutions for the intelligent digitization of their production processes and environments. Manufacturing companies cooperate here specifically with software and hardware providers who want to provide and further develop digital technologies.

The portal can be reached at https://s.fhg.de/ICNAP-digital-services.

ICNAP is funded by the Fraunhofer-Gesellschaft as part of a Fraunhofer Performance Center.