LASER World of Photonics 2022: Optical coherence tomography for more stable and safer laser processing

In laser processes, deviations in the laser's parameters quickly lead to serious defects in the component, which is why it is ideally necessary to react immediately. The Fraunhofer Institute for Production Technology IPT in Aachen has developed a modular system based on optical coherence tomography (OCT) that can detect deviations during laser processing. The Fraunhofer IPT will be presenting the new possibilities for measurement and data acquisition in the ongoing process at the trade fair using a prototype at the "Laser - World of Photonics" trade fair in Munich from April 26 to 29, 2022.

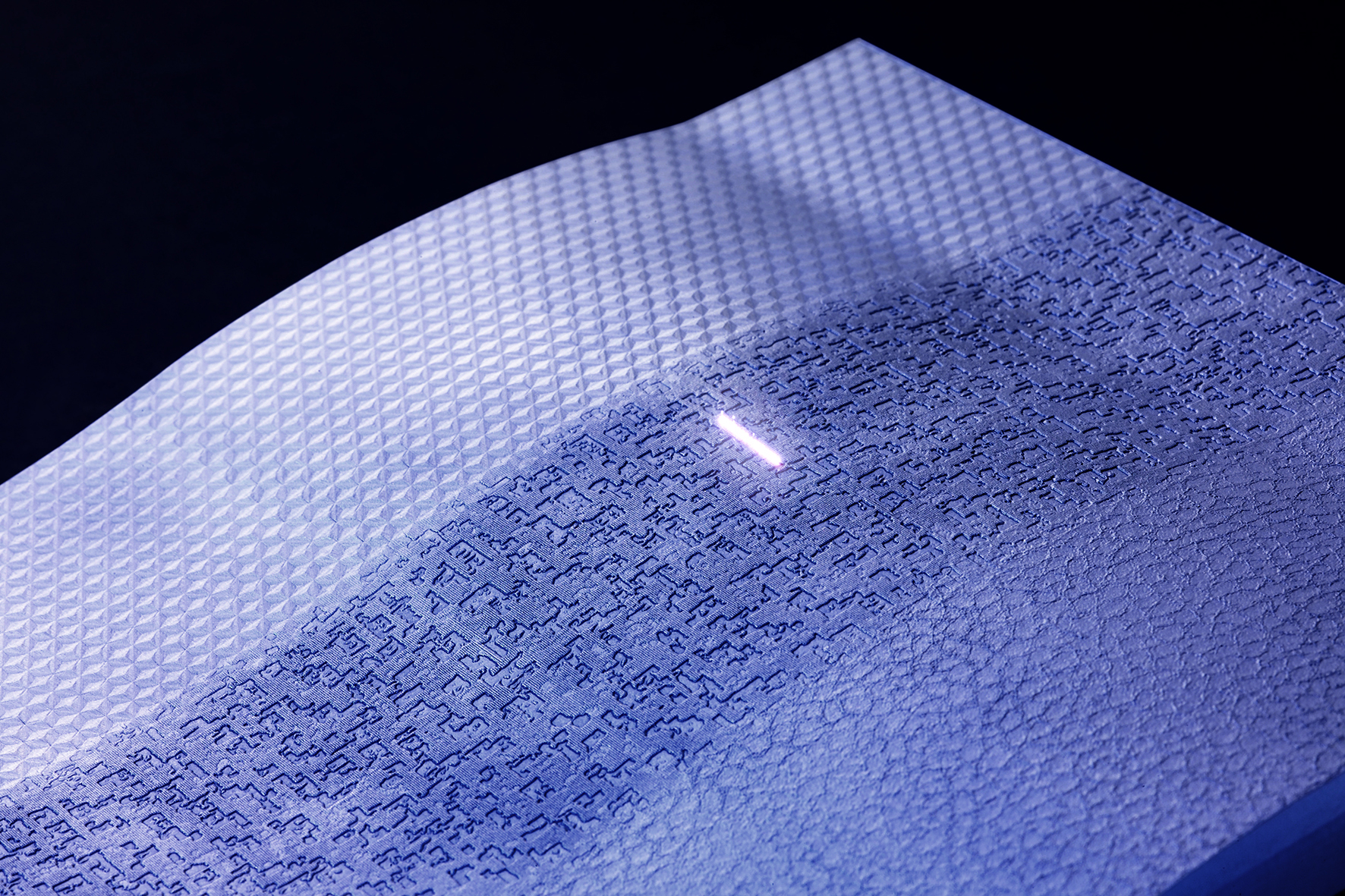

OCT is a non-contact measurement technique that can provide high-resolution two- and three-dimensional images of semitransparent materials and was originally developed for ophthalmology. But with its high measuring frequency of several kilohertz, OCT also makes it possible to measure surface distances of opaque technical components extremely precisely. This makes it possible to check the condition of workpiece surfaces during an ongoing production process. This is of particular advantageous for laser processing, as it allows real-time reaction to change in the process. The OCT system is coaxially integrated into the processing module in a common beam path with the laser. The laser and the OCT system use common optics - but at different wavelengths. This saves space and allows the installation effort of further expensive optics and allows measurements to be performed directly in the process.

With OCT to the adaptive laser process

In the project "ESSIAL - Electrical Steel Structuring, Insulating and Assembling by means of Laser Technologies", the Fraunhofer IPT has integrated an OCT system modularly into an existing laser processing system. Since the optics cannot meet the requirements of both systems equally, it was designed for the laser process. To prevent the OCT system from being damaged by the reflected light of the laser during the machining process, the Aachen researchers integrated a beam splitter into the overall system. This deflects the light from the laser and thus protects the OCT module. During a measurement, the light beam from the OCT system hits the workpiece through the optics at a slight offset to the processing laser. To correct the offset and control the measurement process of the OCT system independently of the laser process, the researchers integrated two scanners into the overall system: While the first scanner is used to control the laser process, the second directs the light beam of the OCT system in such a way that the beam offset is corrected. To compensate for beam misalignment, the Fraunhofer researchers have developed a correction method that determines its correction values based on the optics used. The measurement of the OCT system can thus be performed independently of the laser process. The laser processing is not influenced by the measurement and any number of measurement patterns can be defined. "The further development of machine-integrated OCT enables users and manufacturers of laser systems and special machines to obtain previously unavailable process data and use it for process monitoring, machine calibration or as a data basis for new applications with artificial intelligence," explains Fabian Zechel, research associate at the Fraunhofer IPT.

A first working prototype of the OCT-assisted laser processing system will be on display by the Fraunhofer IPT at the "LASER World of Photonics" trade fair in Munich from April 26 to 29 2022 at the Fraunhofer-Gesellschaft's joint booth in Hall A6, Booth 441.

The EU project "ESSIAL" is funded under the grant number 766437 for four years from the funding measure "EU H2020 RIA FOF-06-2017" of the European Commission.

Project partner

- ESIEE Amiens, Amiens

- Fraunhofer Institute for Production Technology IPT, Aachen

- LASEA, Liège

- CRM Group, Liège

- Jeumont Electronic, Carquefou

- EuraMaterials, Wijnegem

- EREA - Transformers

- MULTITEL, Mons

- Universidad Carlos III de Madrid, Madrid

- Euronovia, Rueil-Malmaison

- IRT M2P, Metz

- ANDALTEC, Jaén

- Université Picardie Jules Verne (UPJV), Amiens