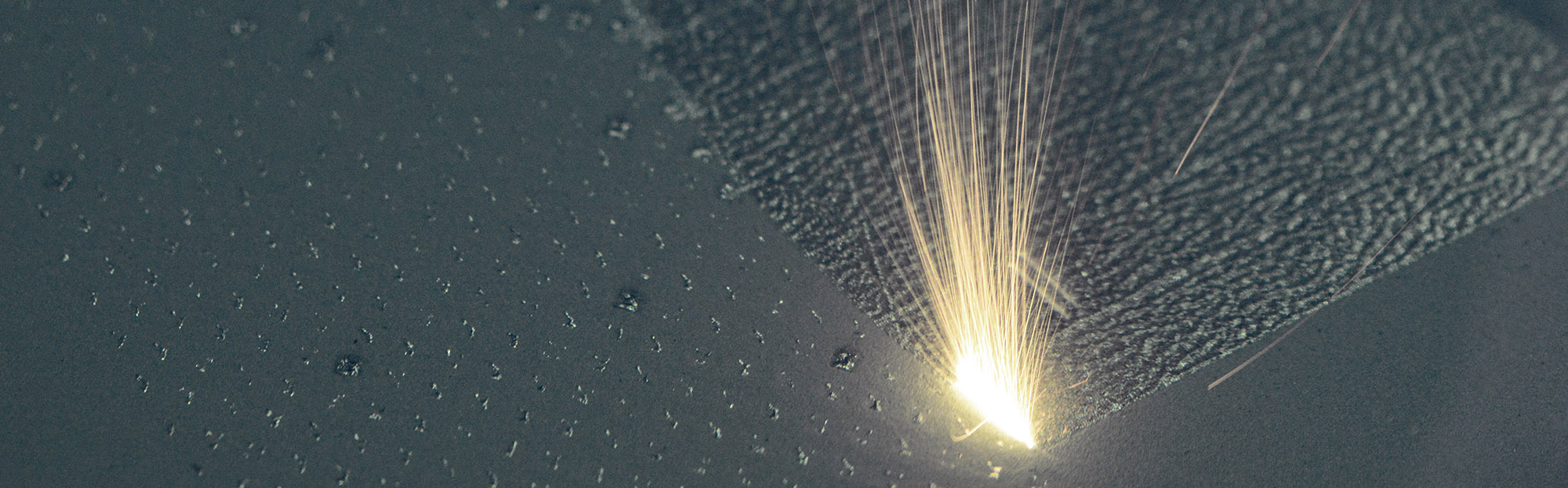

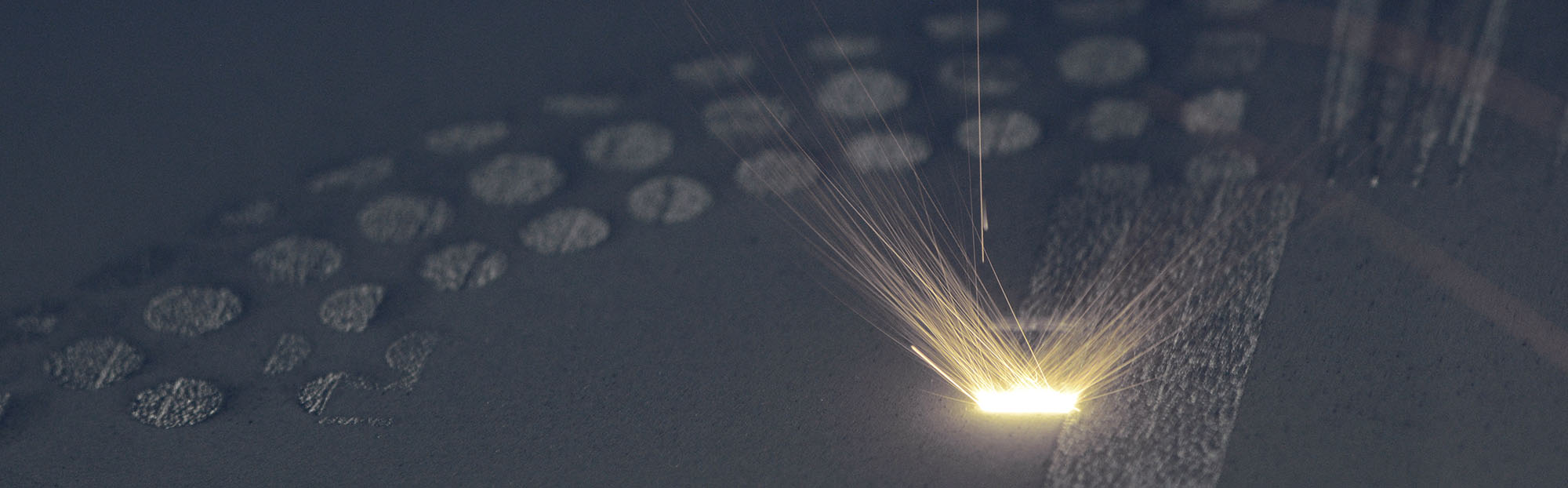

Laser powder bed fusion (LPBF) is one of the best-known additive manufacturing processes. In the LPBF process, components are manufactured by selective laser melting. First, the powder material is evenly applied to the build plate with the coater in a thin layer of 10 to 200 micrometers. The material is selectively melted with a directed laser beam. The build platform is then lowered and the process starts again. In this way, individual melt tracks are created next to each other, which together form a layer. Several layers on top of each other form a component.

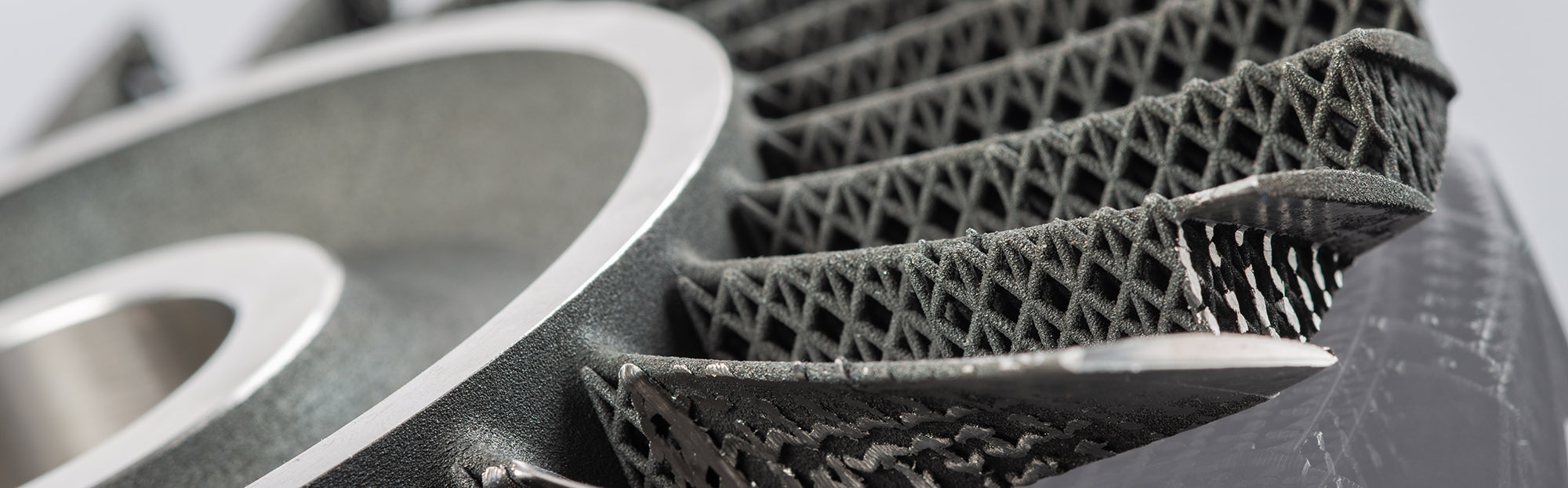

The extremely thin layer thickness enables a high detail resolution of the components. The LPBF process thus contributes to an expansion of the possible component portfolio beyond the limits of conventional production and extends the possibilities of the component geometry that can be realized.

Development of the optimal LPBF process

Like any production process, the LPBF method has advantages and disadvantages. For example, the above-mentioned advantages of the component geometry can be offset by the fact that the LPBF method is comparatively slow and expensive. There is still potential for optimization here, especially for industrial series production. For this reason, Fraunhofer IPT are developing new, optimized production processes for laser powder bed fusion.

In our investigations, we never consider the manufacturing process in isolation, but in the context of the entire process chain. Our researchers from different manufacturing technologies work closely together to realize the best possible process chains. For example, we use manufacturing simulations to identify the best possible LPBF process chain even before actual manufacturing begins. The interdisciplinary collaboration between Fraunhofer IPT and the Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University also guarantees the smooth integration of the LPBF process into our partners' existing process chains.

Integration of LPBF in hybrid production process chains

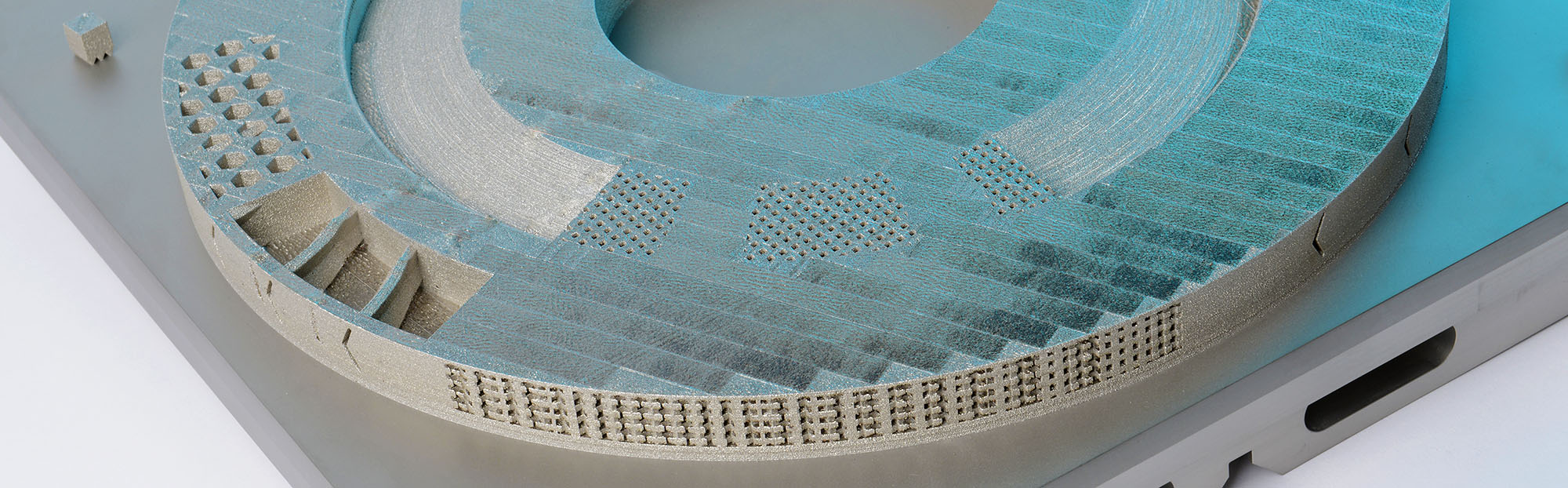

From Fraunhofer IPT's point of view, purely additive assembly of a component using the LPBF process is not always the most cost-effective and time-efficient solution. Therefore, one focus of our research work is the further development and optimization of "hybrid process chains".

By a hybrid process chain we mean the additive build-up of structures on already existing semi-finished products. These semi-finished products can be plates, forged or cast materials. Semi-finished products can also be components that have been pre-machined by means of milling, turning or electrochemical metal machining (ECM), for example, or that are post-machined after the structure has been built up.

Successful integration into hybrid production chains is an essential component for cost-covering use of the LPBF process in an industrial context. Hybrid production processes can save process time and costs because the "expensive" processes are used sparingly and in a targeted manner. Hybrid production extends the range of applications of the LPBF process beyond new part production to include repair processes.

Our services

At Fraunhofer IPT, we develop new production processes for powder bed-based laser beam melting. In our research work, we investigate all steps of the complete process chain. This begins with component design and extends to novel approaches for the production of hybrid manufactured components and the automated removal of support structures, through to optimized post-processing using various methods.