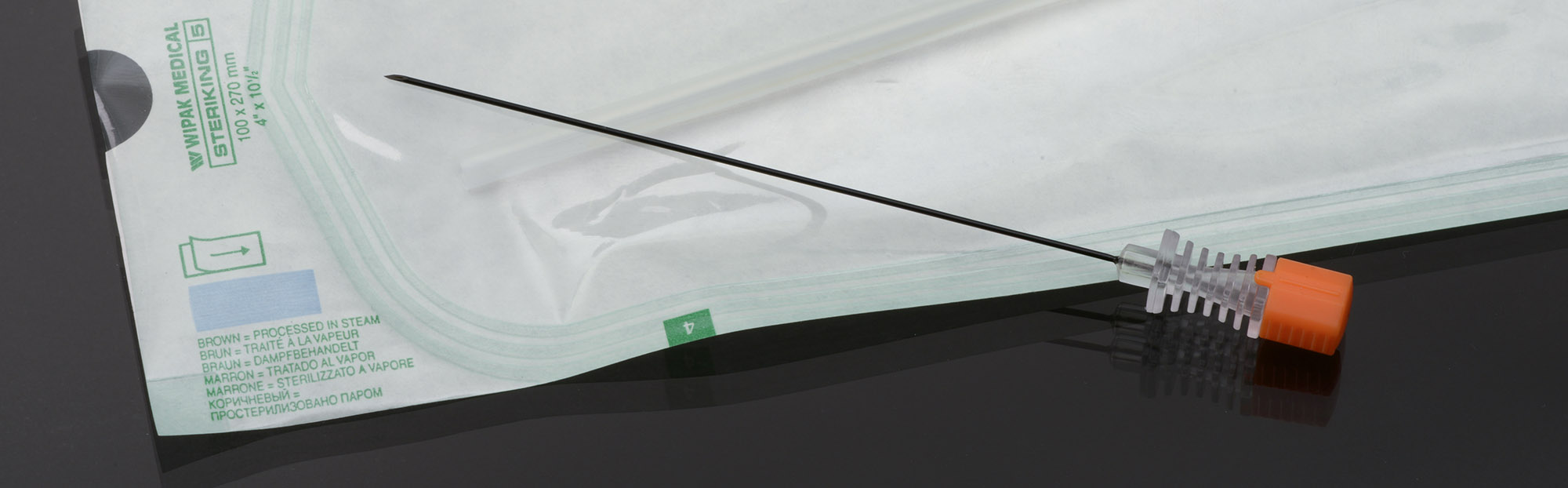

Micro profiles made of fiber reinforced plastics for MRI surgeries and diagnosis

Fiber reinforced plastics offer a valuable alternative to conventional materials for various medical applications: They can be used in magnetic resonance imaging (MRI) without any safety concerns, whereas metals interact with and disturb the magnetic field. At the same time, composites have the mechanical stability and flexibility required to replace instruments, prostheses and implants made of metal. Another advantage: Composite profiles are particularly lightweight and can be customized to perform specific functions. In miniaturized form, they offer enormous potential both for minimally invasive procedures and for post-op checkups without exposure to radiation.

Miniaturized pultrusion and pullwinding

At the Fraunhofer IPT, the micro-pultrusion and pullwinding processes were developed to produce miniaturized components made of fiber reinforced plastics. Our special purpose machines produce profiles with diameters below 500 µm and high fiber volume content. The fiber layers with continuously adjustable orientation are aligned in the micro-pullwinding process giving the profile its specific mechanical properties tailored to the requirements of the application. All commonly-used reinforcing fibers as well as thermosetting and thermoplastic materials can be processed. Customized semi-finished products, such as towpregs, can also be produced economically using the micro pultrusion process.

Our services

- Development and setup of special-purpose machines for micro-pultrusion and micro-pullwinding processes to produce FRP micro-profiles in large scale

- Providing support in terms of material selection, design, development and production planning

- Material qualification of all fiber and matrix materials as well as semi-finished products

- Providing support in the phase of medical certification of micro-pullwinding systems and products

- Consulting services, technology and market studies