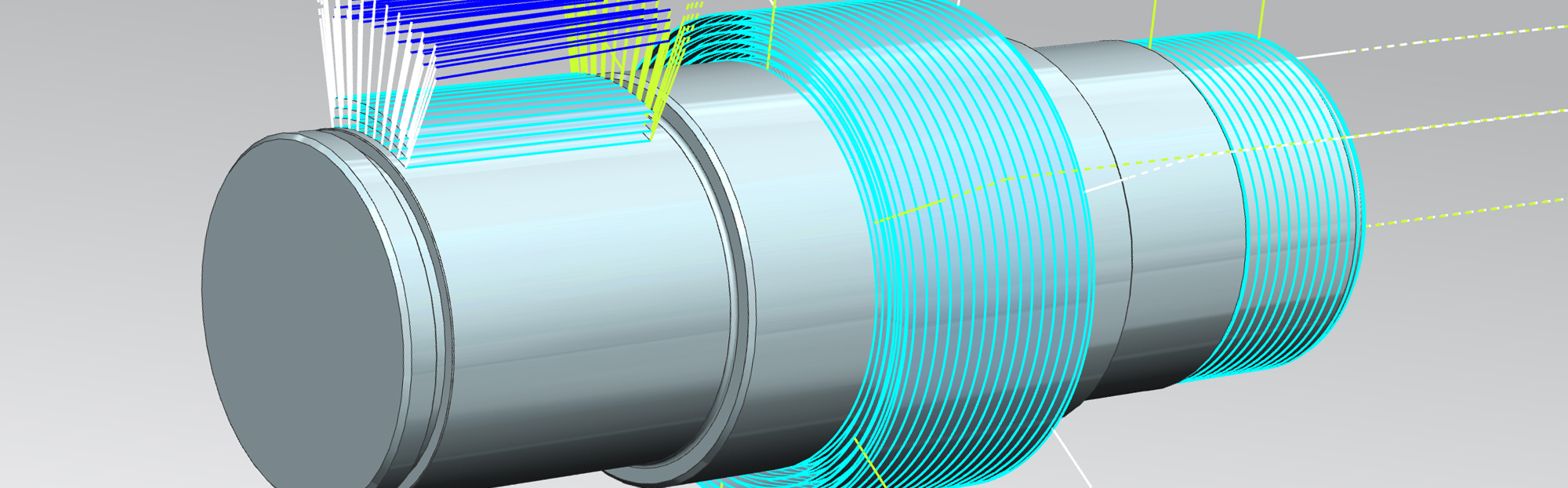

Technology modules combine process knowledge and process design. In the form of CAM modules, they quickly and efficiently provide programs for part and product manufacturing within the tool path and process planning phase. Through graphic interfaces and the integration into CAD environments, CAM modules allow the customized design of application-oriented processes. By combining and linking CAM modules, it is even possible to represent entire process chains, guaranteeing maximum levels of data consistency throughout the processing operation.

The Fraunhofer IPT is developing CAM solutions for a wide range of individual technologies, processes and production facilities in industry and research, for example designing modules with new functions for the use of wire-based laser metal deposition in additive manufacturing processes or for the functionalization of surfaces by laser structuring. We are also developing CAM modules for highly innovative processing functions such as the 5-axis water jet material ablation technology. We have already started also with the design of customized CAM solutions that will be capable of controlling complex robot-based multi-technology centers for several (non-)conventional manufacturing technologies.

Our Services

- Development and implementation of individual CAM modules, according to your specific requirements and existing production machinery

- Process design through our CAM modules

- Customized analyses to identify the potential of new CAM solutions

- Market analyses of CAM solutions for non-conventional manufacturing technologies or process chains