Research project "ToolRep"

Plastic injection molding is one of the most cost-effective manufacturing technologies for large-scale production. Therefore, molds and mold inserts are the most important components as they are responsible for the quality and efficiency of the final products. Finely structured surfaces are applied to the molds in order to give a special product design or functionality to the final plastic part. Grained plastic parts are used in the automobile industry, for instance, where they can be found in dashboards or impact absorbers. During the plastic injection process, wear can occur by using fiber-reinforced plastic material or damages are caused due to wrong handling. In this case, repair is hardly possible these days or it requires a high amount of manual effort. This is a disadvantage for the manufacturing company as it leads to new time-consuming and costly purchases, long repair times or even production stop. In the project “ToolRep” (contract no. 02P14A032), which is funded by the German Federal Ministry of Education and Research (BMBF), Fraunhofer IPT and the Institute for Optical Systems Konstanz as well as four industrial partners jointly develop a holistic repair solution.

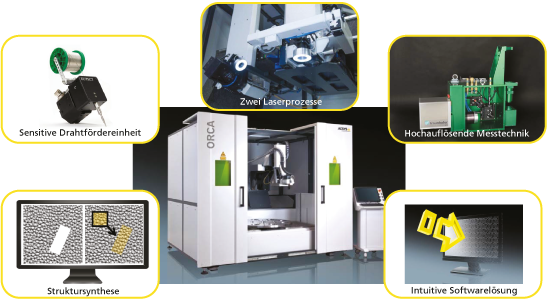

Lösungsweg – Systemlösung zur vollautomatisierten Reparatur

Our Objective

The objective of the research project “ToolRep” is the realization of a hybrid laser machining center for the automated repair of textured injection molds. For this purpose, a complete and consistent process chain for mold repair will be implemented as an automated laser-based process sequence. The combination of wire-based laser metal deposition and laser structuring within one single machine tool, which is controlled by an integrated optical metrology solution, offers the end user significant competitive advantages due to shorter set-up times and a lower space requirement. In addition to the optical metrology, a control technology as well as process monitoring and controlling routines will also be developed within the project. New algorithms for the software-based path planning for both laser processes as well as for the “digital” structural repair – known as texture synthesis – will be implemented into the existing CAM software developed by Fraunhofer IPT. All the results will be merged into the final machine tool demonstrator, which is based on already existing multi-axis machining concepts, and validated. Ultimately, the project results put the project partners in the position where they can offer manufacturers and users a quick and complete repair from a single source.

Project coordination

ACSYS Lasertechnik GmbH

Project partners

- EUTECT GmbH

- Fraunhofer Institute for Production Technology IPT

- Hochschule Konstanz Technik, Wirtschaft und Gestaltung

University of Applied Sciences – Institut für optische Systeme der Fachhochschule Konstanz - Precitec Optronik GmbH

- Werkzeugbau Siegfried Hofmann GmbH

Project management agency

Karlsruhe Project Management Agency (PTKA-PFT)