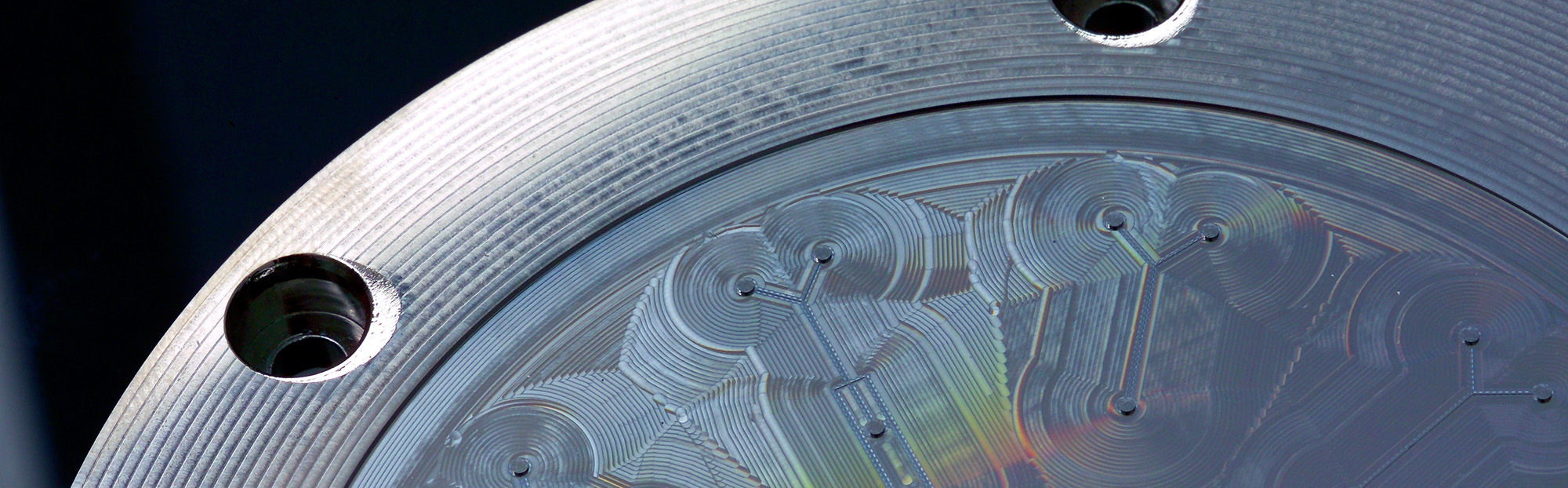

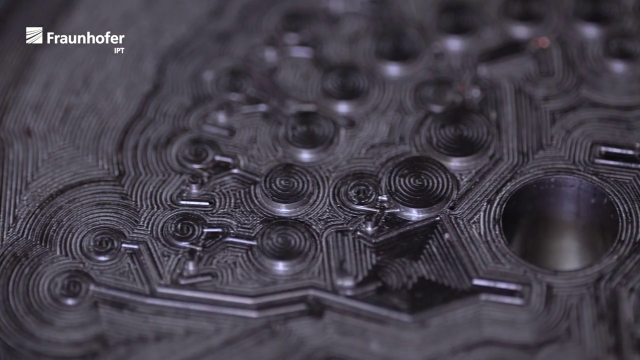

Each injection molding tool is a one-off – making customized tool design a necessity. The Fraunhofer IPT has been working to further develop and refine precision machining for over 20 years and produces high-precision plastic components with very tight tolerances for industrial application. Our focus is on injection molding tools for optical applications and medical engineering products such as Lab-on-a-Chip systems.

We have adapted our product development to hone in on the use of plastic as an engineering material. We accompany our customers from prototype production until the product is ready for mass production: In addition to our in-house tool making facility and our high-precision mold insert manufacture, we are on hand to support you through out the design, optimization and analysis of your product. Our expertise extends far beyond conventional injection molding to include micro-injection molding, injection-compression molding and over-molding. We work closely with our partners to ensure that we can continue to create solutions for our clients even when a cross-disciplinary approach may be required.

Our services

- Analyzing products and optimizing the design of articles

- Feasibility studies conducted using Autodesk Moldflow injection molding software

- 3D-design and related drawings in SolidWorks

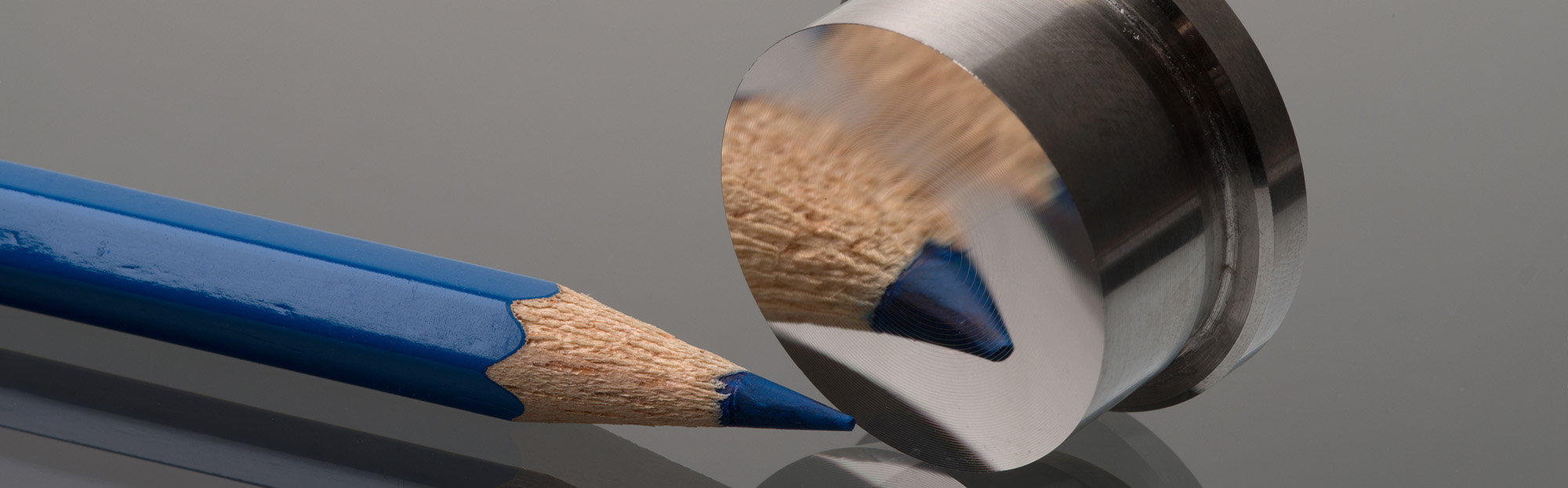

- Tool construction and high-precision mold insert production with tolerances < 0.01 mm

- Optical surface quality for mold inserts with roughness values < 10 nm

- Product development from prototype through to readiness for serial production

- Mold making for conventional injection molding, micro-injection molding, injection compression molding and over-molding