Precise measurements are indispensable for the quality testing of incoming and outgoing products - both for series components as well as for prototypical test specimens from development. Targeted analyses and improvements in the production process also require continuous precise measurement results.

Whether a testing task can be solved with a special measuring principle depends on the geometry of the part, its material properties as well as external boundary conditions, which have to be analyzed in detail. The interpretation of the obtained data and its evaluation also present different challenges, depending on the application. As part of our research assignment for small and medium-sized companies, we provide recommendations for decisions regarding the selection of measuring equipment for quality assurance in production.

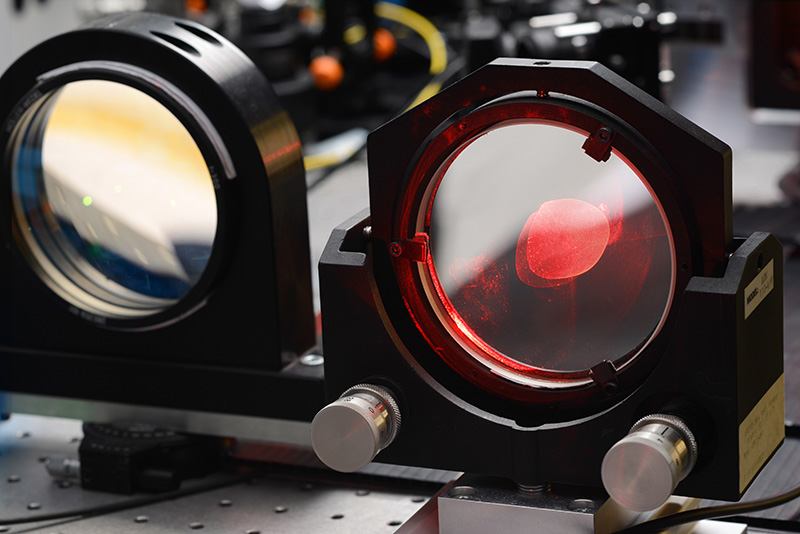

In addition, we carry out individual measurements including data evaluation, logging and feasibility studies. The Fraunhofer IPT has numerous measuring instruments for the characterization of components with dimensions from the metre to the nanometre range at its disposal. Our specialties are high-precision multisensory 3D geometry measurement, submicrometric surface measurements, e.g. for roughness analysis, and optical inspections.