Image processing is an essential part of optical metrology, because any measuring system based on camera technology not only needs to capture images, but also to evaluate them.

The Fraunhofer IPT therefore researches and develops new image processing evaluation methods for metrological tasks. These include classical approaches such as object recognition as well as dimensional measurement and defect classification, but also current approaches based on deep learning methods.

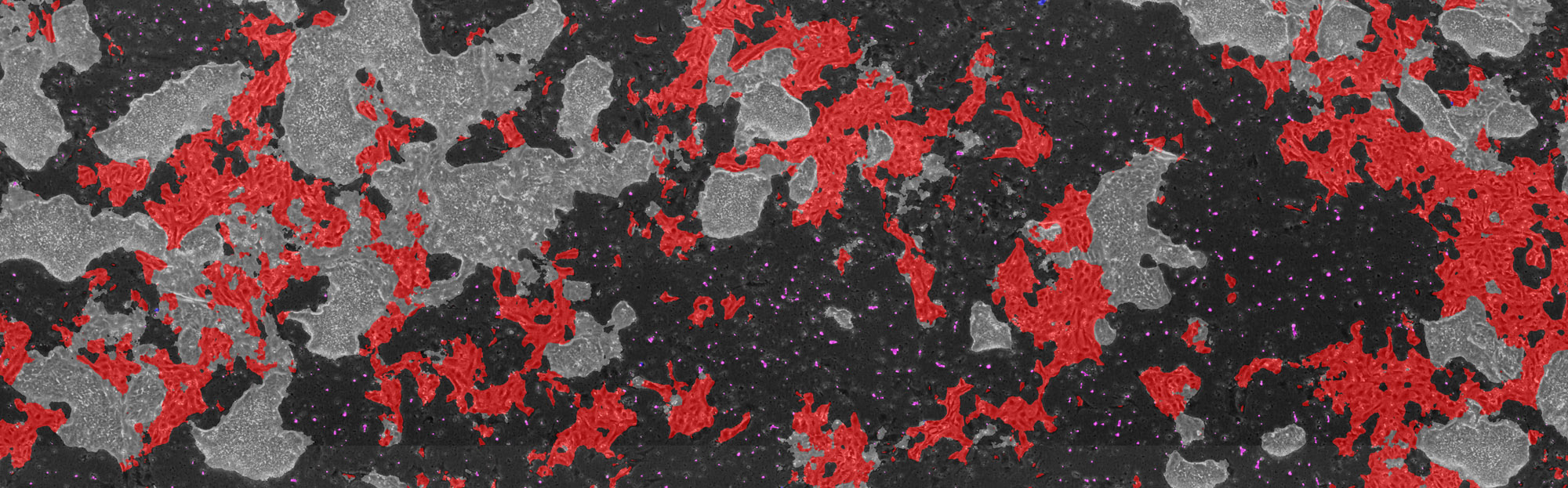

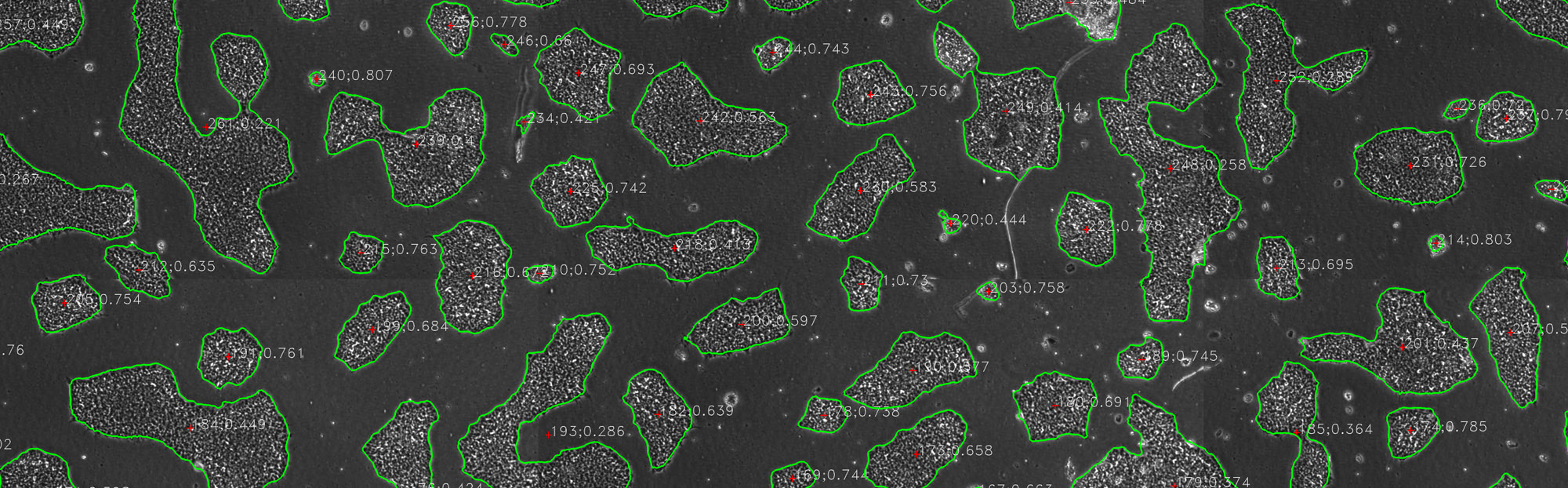

In automated cell cultivation plants, it is necessary to take large microscope images of stem cells in order to calculate key cell culture data such as confluence, location and size of individual colonies. The result of the classification, which is obtained using artificial intelligence approaches, is not only more accurate and robust against external influences, but is also available much faster, thus enabling efficient process control.

For quality control of technical components, image processing algorithms can detect and evaluate errors such as shape and position deviations. The Fraunhofer IPT develops individual algorithms for such automated manufacturing processes and integrates them into existing imaging and processing systems.

Our services

- Conception and development of test software based on deep learning algorithms

- Development of algorithms for quality assurance

- Development of image processing for process control

- Integration in plants and manufacturing processes