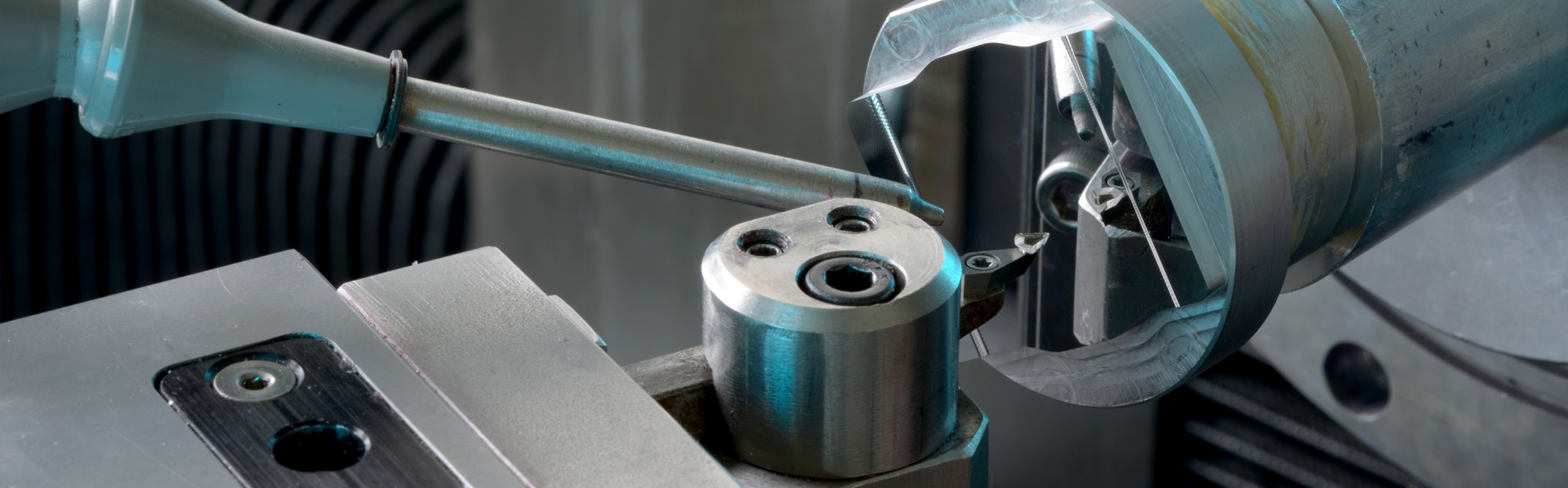

Finishing precision parts

In cutting processes in which a lathe is used, it is the level of process precision that determines whether the turning operation is described as precision, high-precision or ultra-precision. At the Fraunhofer IPT, we have been focusing particularly intensively on ultra-precision turning for a number of years. This process is used to finish precision components with super-finely surfaces and precise dimensional accuracy. Ultra-precision turning is an important manufacturing process, particularly when aspherical and free-form surfaces for optical components or components for medical and technical applications are being machined. It also presents an interesting alternative to grinding for some types of material.

Our offer: Know-how and state-of-the-art machinery

In ultra-precision turning operations, we utilize machines with air-bearing workpiece spindles and monocrystalline diamond tools. These are used to conduct high-precision machining operations in the sub-micrometer range, achieving highest levels of contour accuracy and surface quality even in the case of complex geometries. Our metrology experts ensure reliable qualification of processes and parts.

We draw on extensive experience in ultra-precision turning acquired over decades not only to progress our own scientific developments but also in the projects we undertake in collaboration with partners from industry. Our expertise extends way beyond turning: We maintain very close links and work intensively with staff from other specialist fields within Fraunhofer IPT, including experts from the Process Technology, Industrial Metrology and CAx Technology departments. Our scientific projects focus on process optimization, enhancing surface quality and on extending tool service life.

Our services

- Coordinating and undertaking publicly funded research and development projects

- Conducting feasibility studies into the manufacture of high-precision components

- Optimizing existing turning processes

- Qualifying and establishing new processes