Replicative manufacturing of glass optics with functional microstructures

Microstructures on glass optics can improve the optical performance and enable new functions: Diffractive optics are used to achieve more effective light distribution or to shape the beam in laser systems, for example. Furthermore, the transmission of optical systems can be increased by specially designed anti-reflection (AR) structures. So far, microstructures are brought into the lens’ surface via lithographic processes mainly. These, however, are comparatively time-consuming and high in costs.

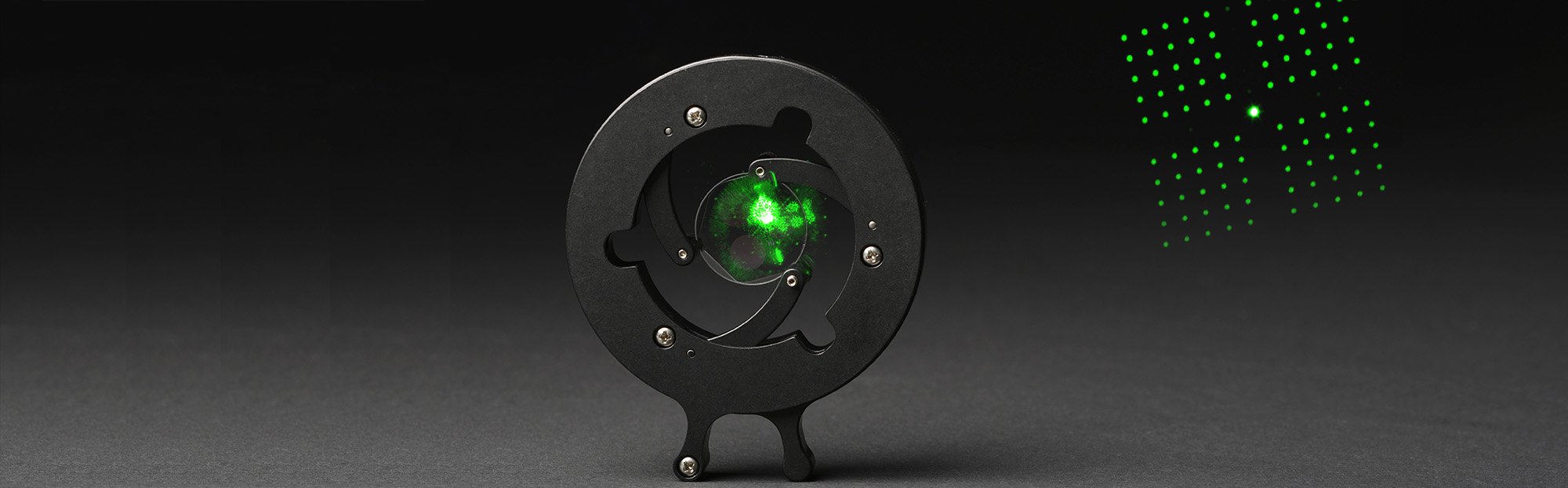

As part of interdisciplinary project teams we are developing a manufacturing technology which can significantly reduce the cost involved in producing microstructured optics: Precision glass molding (PGM) allows the macro-geometric molding and the manufacturing of micro/nanostructures to be carried out simultaneously.

Thus, we can manufacture diffractive optical elements from a range of glass types including fused silica, for example. Furthermore, PGM is able to apply AR-structures on high performance infrared optics made of chalcogenide glass. High-resolution measuring methods such as scanning electron microscopy and atomic force microscopy enable us to provide a qualified assessment as to the quality of the outcome of the replication process.

Services

- Micro/nanostructured glass optics

- Feasibility studies into the production of prototype series

- Geometry- and material-based process design and optimization